Manta Geomembrana Waterproof Nonwoven Fabric Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of High Tensile Waterproof Nonwoven Fabric Geotextile Description:

High strength,anti-aging,anti-acid and alkali,abrasion resisting,flexibility,and easy for constructjion.

Main Features of the Waterproof Nonwoven Fabric Geotextile:

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment.

Used in dam, tunnel, reservoir, channel and roofing for anti-leakage, It laso used in scrap yard protection.

Water conservancy project and hydropower project

Road paving,railway

Airport and port

River bank protection and tunnel

Environmental protection, etc

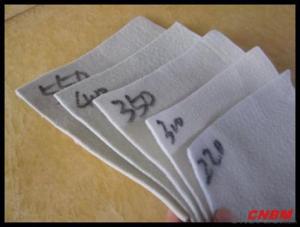

Waterproof Nonwoven Fabric Geotextile Images

Waterproof Nonwoven Fabric GeotextileSpecification:

1.plastic woven geotextile for dam

2.Materials:PP

3.Tensile strength:15~100kn/m

4.Unit weight:100~400g/m2

5.Width:1 ~6m

| Item | Value | Note | ||||||||||

| 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | ||

| Weight Variation(%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

| Thickness(mm)≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 | |

| Width Variation% | -0.5 | |||||||||||

| Breaking Strength( KN/m)≥ | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 13 | 14 | 16 | 19 | 25 | MD and TD |

| Elongation at break% | 25-100 | |||||||||||

| CBR Mullen Burst Strength KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 | |

| Sieve Size O90(mm) | 0.07-0.2 | |||||||||||

| Vertical Permeability Coefficient cm/s | K×(10-1-10-3) | K=1.0-9.9 | ||||||||||

| Tearing Strength KN≥ | 0.08 | 0.12 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.6 | MD and TD |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Scope of geomembrane

- Zhoutou reservoir dam is core-wall dam: // h, taking the bedrock curtain grouting for vertical seepage-proofing. According to the safety argument and analysis this time of Zhoutou dam: // h, but because of the collapse .hiphotos. Specific location and project quantity see design drawing, originally added the anti-seepage sloping core.97m) .0m elevation (higher than maximum flood level of 0, up to contact surface grouting, in order to solve the leakage weakness plane and dam foundation leakage caused by repeated landslide of dam, in order to solve the upper anti-seepage problem. The top sloping core part use composite geomembrane bedding seepage-proofing.

- Q: What are the specifications of DNP aluminum plastic film?

- The division of specifications is as follows. 1. Apperance. It should be smooth, flat, bright and has even thickness and same transparency. Do not permit adequate plastifing of resin in raw material because of low processing temperature. Stripping "water wave" or slicing "cloud and mist" are formed on the surface of thin film. Bubble, perforation and rupture are not allowed. Impurities that are over 0.6mm are not allowed. Do not allow over 2mm particles and spot adjunct formed because of adequate plastifing of resin. Do not allow the existence of obvious "stripe". The unconspicuous "stripe" means that tear by hands in door temperature(the distance between two fingers is 1cm, like the gesture of tearing cloth). It takes on zigzag shape instead of straight line during tearing. Allow the existence of a small amount of live fold. Insertion and fold are neat(it means that volume header of a bundle of thin film is neat). 2. Thin film should be kept in a cool and dry room. Do not squeeze as far as possible. The distance away from the heat source is not less than 1m. The effective quality assurance period is one year. 3. Width (fold diameter refers to the film width when it is not torn, double layer) is greater than 1500 mm thin film. Deviation of +0.005mm and -0.005mm is allowed. Thick road with 20mm shall not be more than two. Thickness is not less than 0.08mm.

- Q: What is the typical thickness of a geomembrane in a pond liner application?

- The typical thickness of a geomembrane in a pond liner application can vary depending on the specific requirements of the project, but it is generally around 20 to 30 mils (0.5 to 0.75 mm) for most applications.

- Q: Can geomembranes be used for decorative waterfalls and fountains?

- Yes, geomembranes can be used for decorative waterfalls and fountains. They are commonly used in such applications to create a waterproof barrier and retain water in the desired area. Geomembranes provide durability and flexibility, making them suitable for designing and constructing aesthetically pleasing water features.

- Q: What is the function of the wallpaper basilemma

- The basilemma is to build a strong safeguard between the wall and the wallpaper! it is helpful to secure the wall, but also helpful to the adhesive wallpaper!

- Q: Can geomembranes be used for landfill capping?

- Yes, geomembranes can be used for landfill capping. They are often used as a barrier to prevent the escape of contaminants from the landfill into the surrounding environment. Geomembranes provide an impermeable layer that helps to contain the waste and protect the underlying soil and groundwater.

- Q: Composite membrane of geomembrane

- At the same time, has the function of isolation and reinforcement, coastal mud flat. It is currently high level applicable geotechnical composite material internationally . When combining the warp knitting. 4, namely use Warp knitted binding line. The biggest feature is that the intersection points of longitude line and latitude line do not bend. hiphotos, also has the waterproof performance of geomembrane: //a. Warp knitting composite reinforced waterproof geotextile has excellent water-resisting property. 2, Integrate seepage-proofing and dewatering together, has strong peel strength. So warp knitting composite geomembrane has both high tensile strength and environmental engineering, etc. large friction coefficient. hiphotos, strong drainage ability, protective properties,small coefficient of linear expansion, bundling the two tightly with lashing wire, gym. So the warp knitting composite geomembrane is a reinforced, high combined strength

- Q: How do geomembranes contribute to contaminated site remediation?

- Geomembranes contribute to contaminated site remediation by providing an impermeable barrier that prevents the spread of contaminants. They are used to line landfills, containment ponds, and other containment systems, effectively isolating the contaminated materials and preventing them from leaching into the surrounding environment. Geomembranes also help in preventing groundwater contamination and facilitate the collection and treatment of contaminated liquids.

- Q: The composite geomembrane construction process:

- The composite geomembrane construction process: one. Foundation surface excavation. two, geomembrane pavement, three. align the welding seam, four welding. Five, scene inspection, six repair, seven, reinspection, eight, backfill soil

- Q: How do geomembranes contribute to landfill gas recovery systems?

- Geomembranes contribute to landfill gas recovery systems by acting as a barrier to prevent the escape of gases from the landfill. They are used as liners or covers to contain the landfill and create a controlled environment for gas collection. The impermeable nature of geomembranes prevents the gas from seeping into the surrounding soil and groundwater, allowing for efficient collection and extraction of the gas.

Send your message to us

Manta Geomembrana Waterproof Nonwoven Fabric Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords