Mahogany Oak Engineered Wood Veneers

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the Oak Engineered Wood Veneer

| Name | Oak Engineered Wood Veneer |

| Type | sliced |

| Length | 2200-3100mm |

| Width | 320-900mm |

| Thickness | 0.15-1mm |

| Thickness tolerance | 0.02mm |

| Grade | A/A Grade |

Instruction of the Oak Engineered Wood Veneer

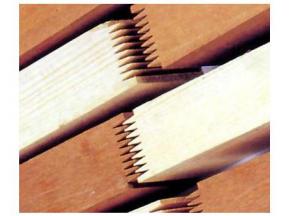

Oak Engineered Wood Veneer is sliced reconstructed real wood veneer, it is made from nature

timber which color is enhanced,reformed to a square and then re-sliced into rectangular veneer

sheets.

The usage of the Oak Engineered Wood Veneer

The engineered wood veneer is applicable for modern new decoration and traditional classic

decoration. And now the engineered wood veneer has mainly developed the following techinical

wood of white oak serious, red oak serious, ebony serious, res sandalwood serious,soluble red

wood serious,zebra serious, cherry serious, walnut serious,wenge serious, and so on. Several

serious and ten of types have been promoted to the markets and hundreds of types are in our

technical storage.

Popular of the Oak Engineeres Wood Veneer

Various types and colors of the The oak engineered wood veneer meet the increasing

individual consumption needs of people. There is at last one type suitable for your selection,

the engineered wood veneers saves your material cost on residential decoration and prevents

you from the trouble of difficult and impossible connection resulted from texture and color of

nature wood. You can make good use of each raw material that you bought.

The following pictures for your reference.

- Q: Advantages and disadvantages of Technology veneer and natural veneer

- much better. the reason is simple. Should be natural for his natural growth without being controlled. The lines will be natural.

- Q: Often, the processing of natural vines is done by slicing the method. The process flow is as follows

- The use of these saws to produce veneer, the board rate is high, the quality of thin wood is better, chopper machine is more efficient.

- Q: What is the veneer process?

- Such as the use of Wan Nengjiao, not environmentally friendly, easy to blister on the paint, arc when the veneer is easy to break,

- Q: The following table lists the cooking criteria for several types of wood,

- The most widely used is the drum dryer. Comparison of thin wood, especially the thickness of less than 0.4mm of thin wood, must use a belt dryer.

- Q: Wooden door with veneer ruled, pattern is produced by different cutting methods

- Sweep veneer can be wide to provide the whole board (single) board.

- Q: The principle of veneer dyeing

- Dyed veneer production process by screening high-quality imported veneer, the use of high-tech processing technology to take off the veneer in the impurities and mineral lines

- Q: Different veneer has different production processes

- . Of course, there are some furniture enterprises to understand the technology more comprehensive

- Q: What is the veneer panel

- Veneer panel commonly known as panel. Is the solid wood board precision cut into a thickness of about 0.2mm meager veneer for the surface layer to the splint as the substrate,

- Q: The Production process of cooking

- The following table lists the cooking criteria for several types of wood, for reference only.

- Q: What is the size of the veneer?

- , imports of veneer up to 3 meters long. Width is generally more than 9 cm wide natural.

Send your message to us

Mahogany Oak Engineered Wood Veneers

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords