LSAW Carbon Steamless Steel Pipe In Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Pipe ASTM A106/53:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

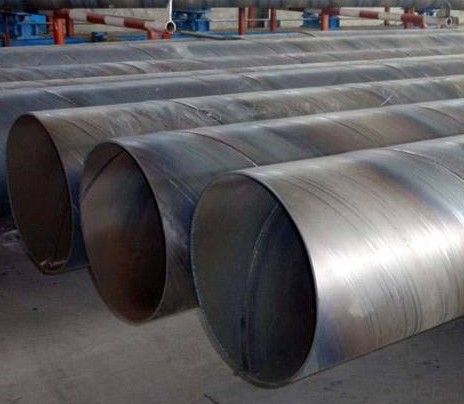

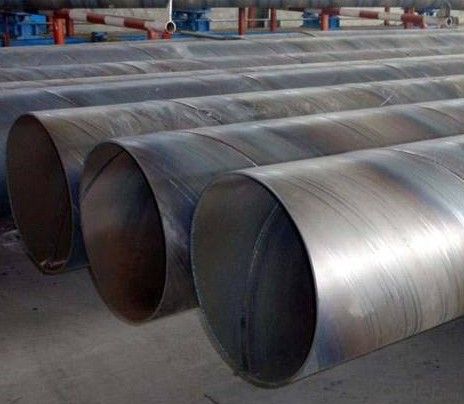

LSAW Steel Pipe

1 Size: 219-3200 mm*5-25.4mm

2 Material Q235/Q345/20#/X42-X65/J55 etc

Standard:

EN-10208-1/2, GB9711.1/2 etc.

Steel Grade:

B, X42 up to X70; L245, L290 up to L48

Usage:

Used for Steel Structure

Size:

LSAW from 219.1mm to 3200mm, thickness from 5mm to 25.4mm

Ends: Beveled ends with protector

Surface:

Bare / Varnish coating / FBE, 3PE coating DIN30670 / or by client option

Packing:

Casing, bundled shipping in containers or by break bulk vessel

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Seamless Pipe ASTM A106/53 Images:

- Q: Can steel pipes be used for water wells?

- Yes, steel pipes can be used for water wells. Steel pipes are commonly used in water well construction due to their durability, strength, and resistance to corrosion. They provide a reliable and long-lasting solution for extracting and transporting water from underground sources.

- Q: How are steel pipes used in desalination plants?

- Steel pipes are used in desalination plants for transporting and distributing water throughout the plant's various processes, such as intake, pre-treatment, reverse osmosis, and post-treatment. They are preferred due to their durability, corrosion resistance, and ability to withstand high pressure and temperature conditions. Steel pipes ensure the efficient and reliable conveyance of water, contributing to the overall effectiveness of desalination plants in producing freshwater from seawater.

- Q: Can steel pipes be used for conveying hazardous chemicals?

- Steel pipes can be used for conveying hazardous chemicals, as they are highly resistant to corrosion and can withstand high pressures. However, it is crucial to consider the compatibility of the chemicals with steel and ensure that appropriate safety measures and protective coatings are in place to prevent any potential leaks or reactions.

- Q: How do steel pipes handle soil movement?

- Steel pipes are highly resistant to soil movement due to their strength and durability. The rigid nature of steel pipes allows them to withstand ground shifting and settling without deforming or breaking. Additionally, steel pipes are often installed with proper anchoring and support systems to further enhance their ability to handle soil movement.

- Q: Can steel pipes be recycled and used for other purposes?

- Yes, steel pipes can be recycled and used for other purposes. Steel is a highly recyclable material, and steel pipes are no exception. Recycling steel pipes helps to conserve natural resources and reduce the demand for new steel production. When steel pipes are recycled, they are typically sent to a recycling facility where they are sorted, cleaned, and processed. The pipes are then crushed into smaller pieces or melted down to be reshaped into new steel products. Recycled steel pipes can be used for a variety of purposes. They can be used in construction projects, such as for building bridges, roads, or buildings. They can also be used in the manufacturing of new steel products, such as automotive parts, appliances, or furniture. Additionally, recycled steel pipes can be used in the energy sector, for example, in the production of wind turbines or oil and gas pipelines. Using recycled steel pipes not only helps to reduce waste and conserve resources but also has environmental benefits. The recycling process requires less energy and produces fewer greenhouse gas emissions compared to the production of new steel. Therefore, recycling steel pipes is a sustainable option that contributes to a circular economy and helps to protect the environment.

- Q: Can steel pipes be used for underground transportation tunnels?

- Yes, steel pipes can be used for underground transportation tunnels. Steel pipes are often used in the construction of underground tunnels due to their durability, strength, and resistance to corrosion. They can efficiently withstand the pressure and weight of the surrounding soil and provide a reliable transportation infrastructure.

- Q: What are steel pipes?

- Steel pipes are hollow cylindrical tubes made from steel, which are mainly used for transporting fluids and gases in various industries such as oil and gas, construction, and plumbing. They are known for their strength, durability, and resistance to corrosion, making them an essential component in infrastructure and industrial applications.

- Q: Are steel pipes suitable for underground installations in areas with high moisture content?

- Yes, steel pipes are suitable for underground installations in areas with high moisture content. Steel pipes are known for their durability and resistance to corrosion, which makes them ideal for withstanding moisture and underground conditions. Additionally, steel pipes can be coated or lined with protective materials to further enhance their resistance to moisture, ensuring their long-term performance and reliability in such environments.

- Q: What are the safety measures to be followed while working with steel pipes?

- There are several safety measures that should be followed while working with steel pipes. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect against potential hazards. Secondly, workers should be cautious of sharp edges or burrs on the pipes and handle them with care to avoid cuts or injuries. Additionally, proper lifting techniques should be employed when moving heavy steel pipes to prevent strains or back injuries. It is also crucial to secure pipes properly during transport or storage to prevent accidents. Finally, workers should be trained on the safe use of tools and equipment associated with steel pipe work to minimize the risk of accidents or damage.

- Q: Can steel pipes be used for conveying liquids and gases?

- Indeed, the utilization of steel pipes extends to the conveyance of both liquids and gases. These pipes find widespread application across a multitude of industries, including oil and gas, water supply, plumbing, and industrial processes. Their commendable attributes encompass robustness, longevity, and resistance to corrosion. Consequently, steel pipes possess the capacity to withstand elevated pressure and temperature, rendering them ideal for the transportation of an extensive array of liquids and gases such as water, oil, natural gas, steam, and chemicals. Furthermore, the convenience of welding or threading steel pipes together facilitates effortless installation and maintenance procedures.

Send your message to us

LSAW Carbon Steamless Steel Pipe In Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords