Lowes Flexible Duct - Aluminum Foil Flexible Duct Ventilation Air Duct

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 litre

- Supply Capability:

- 500000 litre/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

2.Main Features of the Aluminum foil facing:

1. Full flexible, high quality factory thermally insulated duct, for all pressure air

conditioning and ventilation system

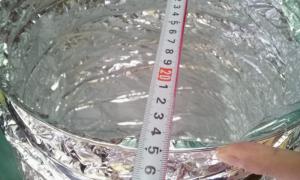

2. Diameter: 82mm to 457mm

3. Temperature range: -30 degree .C to 80 degree. C

4. Air velocity: Max.30m/sec(5906ft/min)

5. Working pressure: Max.300 mm WG(3000Pa or 12 WG)

6. Fireglass Thickness: 25mm

7. Fireglass Density: 16kg/m3-20kg/m3

8. Standard Length: 10m

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: For example, HDPE pipe with a flexible connection is a flexible interface, PVC-U of the glue plug-in method, is just helium pouring a lie on the pizza pull the interface, wire then, flange it more

- According to the provisions of Article 103 of the "Tower Crane Safety Regulations", the tail of the tower crane is not less than 0

- Q: Drain flexible pipe to keep the base design above the elevation of the number of meters

- Flexible pipe with metal materials, such as metal mesh, organ, etc

- Q: Cast iron flexible tube A type B What is the difference

- See JGJ130-2011 "construction of fasteners steel scaffolding safety technical specifications" 'structure of the valve enamel crisp raccoon Yi Yi paralysis nitrogen Kai made requirements'. ... set the steel pipe as a foot, the first step from the first 1.95m, steel pipe spacing of 2m, two steel pipe between the small

- Q: We now have to declare the Department of the Ministry of the United States and the United States, the company said that the access point to our own set, so I would like to ask, what is the requirements of this access point? There is no relevant specification to add: is the construction, the outdoor pipe network in the gas access point position more

- The cost of the main cantilever is as low as the secondary structure can be moved

- Q: Talk about the class flexible management of the class teacher what the requirements

- Hello metal hose made of stainless steel models are mainly single-button type P3 and double button P

- Q: Safety evaluation: gas pipeline and discharge pipe should not be set between the valve, what is the specification of which provisions?

- Usually in accordance with cubic meters or kilograms to calculate the price

- Q: Plastic tube most afraid of what the East unitary

- In general, polyurethane sandwich panels can be used in a variety of building needs, including industrial plants, public buildings, combined housing, purification projects and other construction areas

- Q: Steel Reinforced (HDPE) Polyethylene Helical Corrugated Tubes Warm-Fused-Belt Is Connected or Bonded with Rubber Rings? Ask what?

- EPS board (also known as benzene board) is made of polystyrene board abbreviation. There is raw materials through pre-hair, curing, molding, drying and cutting made. It can be made into different density, different shapes of foam products, but also can produce a variety of different thickness of the foam sheet. Widely used in construction, insulation, packaging, refrigeration, daily necessities, industrial casting and other fields. Can also be used to display the venue, merchandise cabinets, advertising signs and toys manufacturing. At present, in order to meet the national building energy efficiency requirements are mainly used in wall insulation, external wall insulation, to warm.

- Q: To ask why the use of clamps connected to the spray pipe after the flush again after the water there will be a lot of hook link position leakage phenomenon? Thank you! The The

- It should be JGJ130-2001 Ministry of Construction 2001-02-9 approved 2001-06-01 implementation

- Q: Maintenance Skills of Leakage of Fire Pipe Clamp Joint

- On the use of steel pipe rack (double pole) support, the specific step to be self-checking, if it is 9 meters high, should be taken out of the full frame, the middle of the spine set must be standardized, in fact, we usually do high-level conversion layer beam is very common You share the board as a beam {face - line load}. On the line is not very complicated. Circular arc positioning to be accurate, first to do stereotypes better.

Send your message to us

Lowes Flexible Duct - Aluminum Foil Flexible Duct Ventilation Air Duct

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 litre

- Supply Capability:

- 500000 litre/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords