Low Weight,Insulating Refractory Products Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

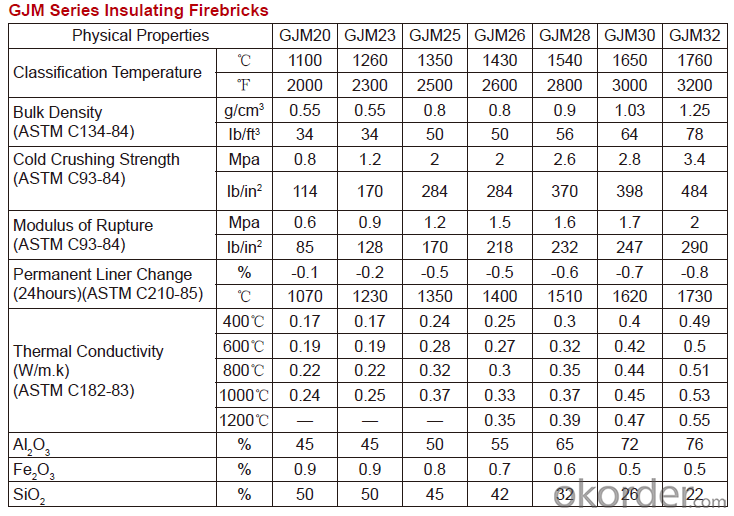

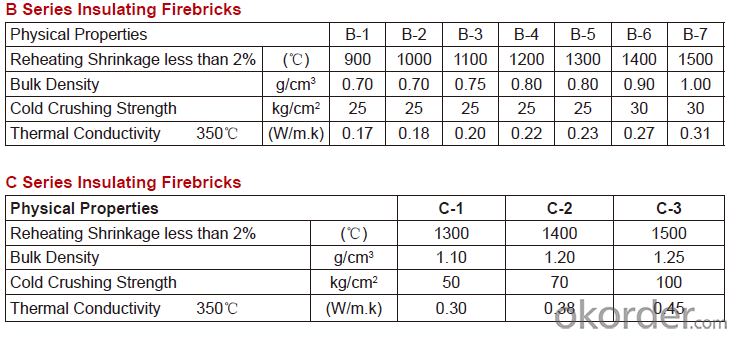

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Are insulating fire bricks resistant to chemical attack?

- Insulating fire bricks are generally known for their resistance to chemical attack. These bricks consist of high-purity refractory materials, such as alumina or silica, which possess excellent chemical stability. Their design allows them to endure high temperatures, making them highly resistant to the corrosive effects of chemicals. However, it's worth noting that the extent of chemical resistance can vary depending on the specific composition of the insulating fire brick and the type of chemical used. In some instances, certain aggressive chemicals may still cause gradual degradation or erosion. Hence, it is always advisable to consult the manufacturer or supplier for precise information regarding the chemical resistance of insulating fire bricks, considering their intended application.

- Q: Are insulating fire bricks suitable for use in autoclaves?

- No, insulating fire bricks are not suitable for use in autoclaves. Autoclaves require materials that can withstand high temperatures and pressure, while insulating fire bricks are designed for insulation purposes and may not have the necessary strength and durability.

- Q: Are insulating fire bricks resistant to thermal conductivity?

- Insulating fire bricks possess the capability of withstanding thermal conductivity due to their design. These bricks are composed of materials that possess low thermal conductivity, such as lightweight refractory fibers or insulating substances like vermiculite or perlite. The main objective of insulating fire bricks is to offer thermal insulation and hinder the transfer of heat, making them a perfect fit for situations where temperature control is of utmost importance, like in kilns, furnaces, or fireplaces. By minimizing thermal conductivity, insulating fire bricks aid in preserving heat within the desired area and minimizing energy loss, thus proving to be an effective insulation choice in high-temperature environments.

- Q: Are insulating fire bricks fireproof?

- Indeed, insulating fire bricks possess fireproof properties. Their design allows them to endure elevated temperatures while offering insulation to impede heat transfer. Composed of refractory materials with a high melting point, insulating fire bricks can withstand intense heat without disintegrating or liquefying. These bricks are frequently employed in scenarios involving high temperatures, such as kilns, furnaces, fireplaces, and ovens. As a means of fireproofing, insulating fire bricks are highly recommended due to their exceptional thermal insulation capabilities and their ability to effectively safeguard against the propagation of fire.

- Q: Can insulating fire bricks be used as a lining for incinerators?

- Yes, insulating fire bricks can be used as a lining for incinerators. Insulating fire bricks have excellent thermal insulation properties, which help to reduce heat loss, increase energy efficiency, and maintain high temperatures within the incinerator. Additionally, they can withstand high temperatures and provide good resistance to thermal shock and chemical erosion, making them suitable for lining the walls, floors, and roofs of incinerator chambers.

- Q: Do insulating fire bricks have a high insulating capacity?

- Insulating fire bricks possess a remarkable capacity for insulation. Crafted with utmost precision, these bricks exhibit exceptional thermal insulation characteristics, rendering them exceptionally proficient in obstructing heat transfer. Their composition entails lightweight materials like ceramic fibers, known for their minimal thermal conductivity. Consequently, insulating fire bricks adeptly capture and maintain heat, effectively thwarting its escape and ensuring adequate insulation of the surrounding space. Owing to their superior insulating capacity, these bricks find extensive utilization in domains that prioritize heat retention and energy efficacy, including furnaces, kilns, and fireplaces.

- Q: Can insulating fire bricks be used in chimneys or flues?

- Insulating fire bricks are not recommended for use directly in chimneys or flues. While these bricks are designed to withstand high temperatures, they are primarily used for insulation purposes rather than as a structural component. Chimneys and flues require bricks that are specifically engineered to withstand the intense heat and corrosive byproducts of combustion. These bricks, known as refractory bricks, are designed to have high thermal resistance and exceptional durability to ensure the safe and efficient operation of the chimney or flue. Therefore, it is advisable to use refractory bricks instead of insulating fire bricks when constructing or repairing chimneys and flues.

- Q: What are the different sizes available for insulating fire bricks?

- Insulating fire bricks come in various sizes to accommodate different construction and insulation needs. The sizes available for insulating fire bricks can vary depending on the manufacturer and the specific requirements of the project. However, some commonly available sizes include standard bricks measuring 9" x 4.5" x 2.5", which are commonly used in residential and commercial applications. Additionally, smaller sizes such as 9" x 4.5" x 1" or larger sizes like 12" x 6" x 3" may also be available. It is important to note that these sizes are just examples and the actual sizes and dimensions can vary. It is always recommended to consult with the manufacturer or supplier to determine the specific sizes available for insulating fire bricks for your particular project.

- Q: Are insulating fire bricks resistant to chemicals?

- Yes, insulating fire bricks are generally resistant to chemicals. They are specifically designed to withstand high temperatures and resist the corrosive effects of chemicals, making them suitable for various industrial applications.

- Q: Can insulating fire bricks be used for insulation in chemical plants?

- Yes, insulating fire bricks can be used for insulation in chemical plants. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for insulating equipment, furnaces, and other structures in chemical plants where heat management is crucial.

Send your message to us

Low Weight,Insulating Refractory Products Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords