Low Price Automatic conveyor made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low Price Automatic conveyor made in China

Description of Low Price Automatic conveyor made in China

The roller dragging the work plane transmission movement is used to achieve the purpose of the production process. The assembly line assembly mode is adopted in the assembly line, and the number of stations and the distance between the rollers can be set according to the process requirements.

Main Features of Low Price Automatic conveyor made in China

Structural form:From the driving form, there are power, no power, and electric roller. According to the layout, it is divided into horizontal conveying, inclined conveying and turning conveying.

Size specifications:The width of the roller conveyor is specified by the customer and can be made according to customer's requirements. The standard turning inner radius of turning roller line is 300, 600, 900, 1200mm, etc. Other special specifications can also be used according to customer's requirements. The drum diameter used in the straight section drum is 38, 50, 60, 76, 89mm and so on. The taper of the turning drum is designed based on the weight, size, and line speed of the conveyed object.

Rack material:carbon steel spray, stainless steel, aluminum profiles.

Power mode: gear motor drive, electric roller drive and other forms.

Transmission mode: single sprocket, double sprocket, O-belt, plane friction transmission belt, timing belt and so on.

Speed control method: frequency control, stepless speed change, etc.

Equipment characteristics: easy to connect between the drum line filter, can use a number of roller lines and other conveyor equipment or special machine to form a complex logistics delivery system and diversion confluence system, to complete a variety of process needs. Accumulation drum can be used to achieve the accumulation of materials. Roller line structure is simple, high reliability, easy to use and maintenance, power roller line considering the tensile strength of the chain, the longest single line length generally does not exceed 10 meters.

Specifications of Low Price Automatic conveyor made in China

| Line length | According to customer's process needs |

| Line width | According to customer's process needs |

| Roller spacing | According to customer's process needs |

| Face width | 750±25mm (selected value) |

| Recommended speed | Mechanical fixed type, electromagnetic control type, frequency conversion type |

| Operation mode | Continuous, beat |

| Scope of application | Electromechanical, home appliance product assembly, transportation, packaging |

Structure type:According to the driving mode, it can be divided into power roller line and non-power roller line, and can be divided into horizontal conveying roller line, inclined conveying roller line and turning roller line according to the arrangement form. Can also be specially designed according to customer requirements to meet the requirements of various types of customers. The standard gauge drum line width is 200, 300, 400, 500, 1200mm and so on. Other special specifications can also be used according to customer requirements. The standard turning inner radius of the turning drum line is 600, 900, 1200mm, etc. Other special specifications can also be used according to customer requirements. The drum diameter used in the straight section drum is 38, 50, 60, 76, 89mm and so on.

Applications of Low Price Automatic conveyor made in China

For mineral water, juice, beverage, liquor, beer, infusion bottles and other product development, speciality, stable performance, product packaging, fastening, beautiful.

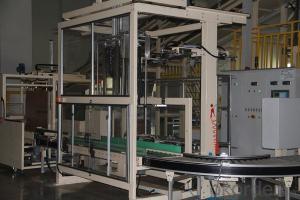

Images of Low Price Automatic conveyor made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q: What is the general packing cost of beer beverage packaging?

- Beer beverage hot shrink packaging generally use PE heat shrinkable film, packaging temperature is usually in accordance with the film material and thickness to set,

- Q: What are the main functions of packaging machinery?

- In order to meet the requirements of many customers, our company has learned from all aspects of the role of packaging machinery and equipment, so that we need customers for reference

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- In today's world, the upgrading of packaging machinery and equipment and production lines are far ahead of Japan, which has earned a large number of dollars in this field. Southeast Asian Four Dragons also follow Japan, a heart in the performance of manufacturing packaging machinery equipment and production lines; in the European community, Italy packaging machinery equipment and production line upgrading faster than other members faster.Renewal is the means of replacing the local parts and components or key components and key technologies, so as to achieve the replacement of one of the unit, so that the original packaging machinery equipment or production line production capacity, performance, efficiency, and assembly way of updated models. In this way, most parts and machine parts are reused, which can improve the equipment value, save the raw materials and the labor force, and reduce the cost. This development trend shows that the packaging machinery, equipment and production lines are becoming more and more standardized, serialized, integrated, integrated and on-line. Civilian, military and high technology will also be more and more widely used in the field of packaging machinery equipment. Fierce market competition will undoubtedly speed up the upgrading of packaging machinery and equipment in all walks of life and technological transformation.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q: What is the name of the paper used in packing machine parts and yellow?

- Also, according to the use of composite PE or textile cloth, in order to improve the physical strength and tightness.Hope to help you.

- Q: What is the delay time of the packer's cross sealing?

- The sealing time is how long the delay is when the sealing dies are joined together.

- Q: What are the structures of the packaging machinery?

- Is far from a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on. It is well received by Chinese enterprises!

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

- Q: Energy saving reform of packaging machine

- First, the working principle of food packaging machinePillow type automatic packaging machine of the present domestic leading and most mature and reliable design and production technology, the essence of a collection of many years of experience in the field of packaging machinery, the packing machine can be used in a variety of composite packaging film coil on the packaging of bulk food, very suitable for the majority of users need to Chinese. 1) the electrical parts of the automatic packing machine are usually made up of the following parts:

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

Low Price Automatic conveyor made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords