Low Price Automatic packaging line made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low Price Automatic packaging line made in China

Description of Low Price Automatic packaging line made in China

Robotic palletizers are suitable for chemical, beverage, food, beer, plastics, air conditioning and other manufacturing companies to box and palletize, canned, boxed, bottled, and other shapes of finished products. The structure is very simple, easy to maintain and repair; the main components of fewer parts, fewer parts, so the maintenance costs are very low; robot hand palletizing machine can be set in a narrow space, you can effectively use; all control can be operated on the control cabinet screen , the operation is very simple. Can work all day, equipped with robots can replace the workload of many workers.

Main Features of Low Price Automatic packaging line made in China

Automatic L-type sealing and shrinking packaging machine is a fully automatic unmanned packaging machine, which can be used with automatic packaging lines. Feeding, bagging, sealing and shrinking are automatically completed. With high work efficiency, it is widely used in mass production industries such as printing, color box, greeting cards, photo albums, photo frames, medicine, electronics, daily chemicals, and cosmetics.

★ Sealing knife adopts imported special materials, the surface coating adopts DuPont FRON high-temperature resistant anti-sticking material to ensure that the sealing does not crack, and the sealing line is strong;

★ The use of horizontal and vertical two sets of photoelectric, easy to switch, for thin or small products, can easily complete the packaging;

★ Automatic feeding, the length can also be automatically adjusted by the combination of photoelectric and timer, equipped with induction motor, automatic winding waste;

★ When the package size changes, the adjustment is very simple, without changing the mold and bag device;

★ Seal cutter with automatic protection function to effectively prevent accidental cutting of packaging;

★ Sealing and cutting part is equipped with plexiglass protective cover, and has an automatic alarm function, which greatly improves operator's safety;

★ The sealing and heat shrink packaging are continuously and automatically completed. The performance is stable, the manpower is greatly saved, the quality is reliable, the contraction efficiency is high, and the applicability is strong.

Specifications of Low Price Automatic packaging line made in China

| Package Size | L500×W400×H200mm |

| Furnace cavity size | L1000×W450×H250mm |

| Packing speed | 20-40 pieces/minute |

| Net weight | 185kg |

| Power | 10kw |

| Power supply | 380v 50/60Hz |

| Maximum current | 30A |

| Machine size | L1300×W715×H1455mm |

Applications of Low Price Automatic packaging line made in China

Robotic palletizers are suitable for chemical, beverage, food, beer, plastics, air conditioning and other manufacturing companies to box and palletize, canned, boxed, bottled, and other shapes of finished products.

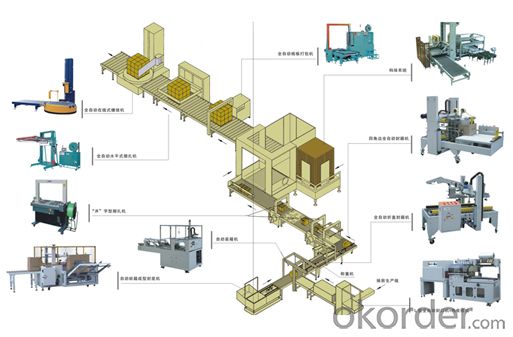

Robotic palletizers can be integrated in any production line to provide intelligent, robotized, and networked production sites, palletizing logistics for a wide variety of jobs in the beer, beverage and food industries. They are widely used in cartons, pharmaceuticals, chemicals, and beverages. , food, beer, plastics, air conditioners, plastic boxes, bottles, bags, drums, film bags and filling products. Supporting three-in-one filling lines, etc., for all types of bottles and bags for palletizing. The automatic operation of the palletizing machine is divided into steps such as automatic feeding, transfer, sorting, stacking, shifting, stacking, feeding, down stacking, and exporting.

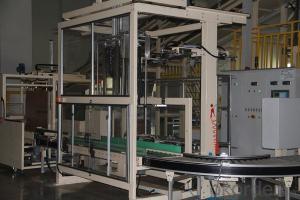

Images of Low Price Automatic packaging line made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q: The role of food packaging machinery

- 3) to achieve manual packaging can not achieve the operation, some packaging operations, such as vacuum packaging, inflatable packaging, body packing, isobaric filling, etc., are manual packaging can not be achieved, can only be achieved by mechanical packaging.(4) can reduce labor intensity, improve the working conditions of the labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease. Carton folding machine(5) in favor of labor protection for some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the cost of packing and save the storage and transportation expenses. It can reduce the volume and reduce the packing cost by compressing and packing the loose products, such as cotton, tobacco leaf, silk and hemp. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.(7) ensure product health of certain products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.

- Q: What is the general packing cost of beer beverage packaging?

- Beer beverage hot shrink packaging generally use PE heat shrinkable film, packaging temperature is usually in accordance with the film material and thickness to set,

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- Hello, in recent years, Chinese packaging industry, although the annual growth rate ranked in the traditional industry for the first time, but in line with the international market, to accelerate the development of packaging technology, make its development to the economic, efficient, multi-functional direction. According to the development plan of Chinese national economy and to realize well-off life level, this year a few years for the packaging industry, the food industry to provide equipment for 100 billion yuan to 200 billion yuan, 80 billion yuan to 100 billion yuan to provide equipment for the "vegetable basket", this is a good opportunity for development of enterprises. At the same time, I learned from the relevant ministries, "95" period, will invest 10 billion yuan in the packaging industry to support and transform large and medium-sized packaging enterprises.

- Q: What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;Can use blister sealing machine or high frequency plastic welding machine hot pressing;

- Q: What are the structures of the packaging machinery?

- Is a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on.

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

Low Price Automatic packaging line made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords