Automatic box wrapping machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic box wrapping machine made in China

Description of Automatic box wrapping machine made in China

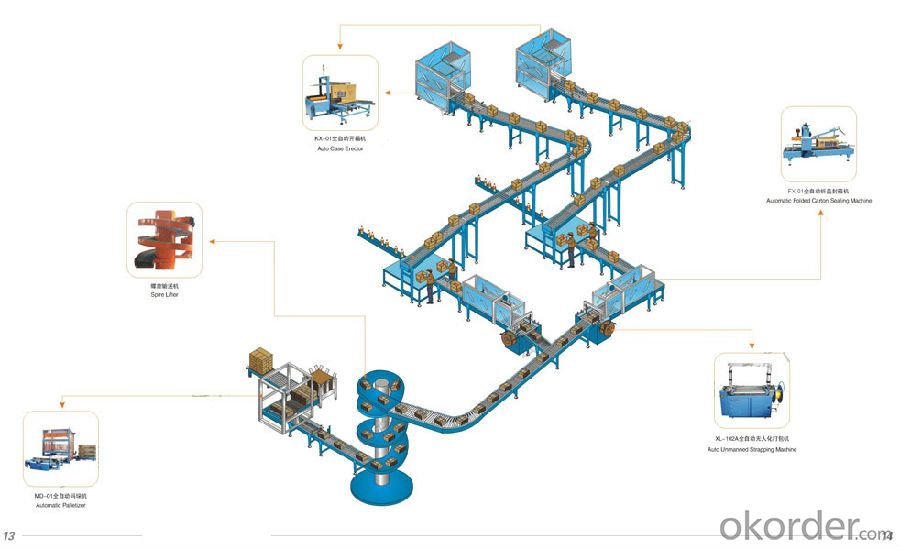

Packaging machinery refers to machinery that can complete all or part of the product and product packaging process. The packaging process includes major processes such as filling, wrapping, and sealing, as well as related processes such as cleaning, stacking, and disassembling.

In addition, packaging also includes processes such as metering or stamping on packages. The use of mechanical packaging products can increase productivity, reduce labor intensity, adapt to the needs of large-scale production, and meet the requirements of cleanliness and hygiene.

Main Features of Automatic box wrapping machine made in China

★ The seal cutting line adopts imported special materials, and the surface coating adopts DuPont FRON high temperature resistant anti-sticking material to ensure that the sealing does not crack and the sealing line is firm;

★ Adopt horizontal and vertical two sets of photoelectric, easy to switch, for thin or small products, can easily complete the packaging;

★ Automatic feeding, the length can also be automatically adjusted by a combination of photoelectric and timer, equipped with induction motor, automatic winding waste;

★ When the package size changes, the adjustment is very simple, without changing the mold and bag device;

★ Seal cutter with automatic protection function to effectively prevent accidental cutting of packaging;

★ The sealing and cutting part is equipped with a plexiglass protective cover and has an automatic alarm function, which greatly improves the operator's safety;

★ Sealing and heat shrink packaging are continuously and automatically completed, the performance is stable, the manpower is greatly saved, the quality is reliable, the contraction efficiency is high, and the applicability is strong.

Specifications of Automatic box wrapping machine made in China

| Model | GWS-6030 | GWS-6040 |

| Machine Parameters | L2600*W1350*H2000 | L2700*W900*H300MM |

| Cutter size and Cavity size | 700mm | L1800*W600*H400 |

| Package Size | W*H≦700MM | L1500*W450*H300 |

| Packing Speed | 6~14 pieces per minute | 20~80 pieces per minute |

| Power | 2KW | 22KW |

| Use gas source | 6kg per square centimeter | |

| Using electric | 220v~380v50~60hz | 220v~380v50~60hz |

| Maximum current | 10A | 35A |

Applications of Automatic box wrapping machine made in China

For mineral water, juice, beverage, liquor, beer, infusion bottles and other product development, speciality, stable performance, product packaging, fastening, beautiful.

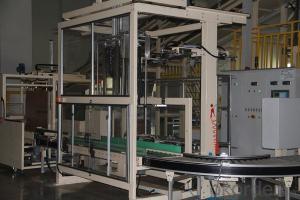

Images of Automatic box wrapping machine made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q: What are the main functions of packaging machinery?

- Eight main functions of packaging machinery and equipmentPacking is a necessary condition for products to enter the circulation field

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping of objects of different shapes according to their appearance.

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- In today's world, the upgrading of packaging machinery and equipment and production lines are far ahead of Japan, which has earned a large number of dollars in this field. Southeast Asian Four Dragons also follow Japan, a heart in the performance of manufacturing packaging machinery equipment and production lines; in the European community, Italy packaging machinery equipment and production line upgrading faster than other members faster.Renewal is the means of replacing the local parts and components or key components and key technologies, so as to achieve the replacement of one of the unit, so that the original packaging machinery equipment or production line production capacity, performance, efficiency, and assembly way of updated models. In this way, most parts and machine parts are reused, which can improve the equipment value, save the raw materials and the labor force, and reduce the cost. This development trend shows that the packaging machinery, equipment and production lines are becoming more and more standardized, serialized, integrated, integrated and on-line. Civilian, military and high technology will also be more and more widely used in the field of packaging machinery equipment. Fierce market competition will undoubtedly speed up the upgrading of packaging machinery and equipment in all walks of life and technological transformation.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q: What are the main functions of packaging machinery and equipment?

- Such as cleaning, stacking and disassembly. In addition, also includes the measurement or the package seal etc.

- Q: The role of packaging equipment in packaging equipment

- Some products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.(8) it can promote the development of related industriesPackaging machinery is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, any discipline problems will affect the overall performance of packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.

- Q: What is the delay time of the packer's cross sealing?

- The sealing time is how long the delay is when the sealing dies are joined together.

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;But to use the hot pressing machine there is to do bakelite mold. Our company specializing in the production of blister, in addition to help customers hot packaging, directly to the finished products to customers

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Mechanical sales are nothing more than two points: first, equipment aging, need to update; two, equipment efficiency is low, need to improve. You don't know anything about the customer. Come up and sell the product. If you are a customer, I don't think you have the patience to listen

Send your message to us

Automatic box wrapping machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords