LOW CREEP FIRECLAY CHECKER BRICKS FOR HOT BLAST FURNACE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | Low Creep Fireclay Checker Bricks for Hot Blast Furnace |

Material | Fire Clay |

Quality Code | DRN120, DRL125 |

Al2O3 | 40 - 42% |

Supply Ability | About 100000 tons per year |

Package | Wooden pallet with plastic films |

Loading port | Tianjin port |

Lead time | 30 days for 300 tons To be confirmed for other quantities |

Features

1. Very low creep rate

2. Excellent Refractories under Load

Technical data for LOW CREEP FIRE CLAY BRICK DRN-120

ITEMS | UNIT | VALUE |

Al2O3 | % | ≥42 |

Fe2O3 | % | ≤2.5 |

Bulk Density 体密 | g/cm3 | 2.1 |

Apparent Porosity 气孔 | % | ≤24 |

CCS 常温耐压强度 | Mpa | ≥35 |

0.2 MPa RUL 荷软, 0.2MPa | ℃ | ≥1400 |

Refractoriness 耐火度 | ℃ | ≥1750 |

0.2 Mpa Creep Rate 1200℃×(0~50)h 蠕变率, 0.2MPa, 1200℃×(0~50)h | % | ≤0.8 |

Photos

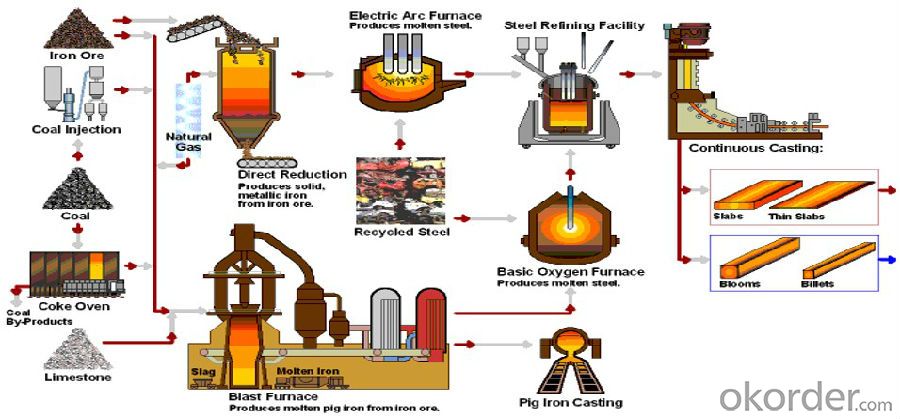

Refractories for all process in steel mills

Factory photos

Package

Company profile

CNBM Group is short for China National Building Materials Group Corporation, which is established in 1984 with approval from the State Council

CNBM Group is the largest comprehensive building materials industry group in China.

CNBM Group is listed No.187 in on Fortune Global 500, 2020.

Refractory is one of the main products of the group. At the same time, under the globalization strategy, CNBM International is the exporter, logistic and local service supplier.

- Q: The matching ratio of masonrying refractory bricks cement

- When building refractory bricks, use matching chamotte, do not use cement

- Q: High alumina refractory bricks (Universal arc) weight for hot metal ladle

- Climbing, C23B ladle generally use T3 ladle bottom brick, brick wall with C23 package, C231 Some permanent layers are built from high alumina bricks, and some are built from castable refractory, T82, T43. Specific size can be checked according to the type of brick

- Q: refractory bricks of fireclay

- According to the preparation process, it can be divided into bricks, high alumina brick, magnesia brickand so on, such as refractory clay brick, and ordinary brick; according to the shape and size, it can be divided into standard brick and silica?brick, it can withstand all kinds of physical and chemical changes and mechanical action at high temperature; silica?brick can be used as high-temperature building materials and structural material to build kiln and kinds of thermal equipments. Refractory material and fused brick with a certain shape and size are called refractory?brick for short.

- Q: Does circulating fluidized bed boiler's furnace wall use refractory to have thermal insulation?

- Heat insulation cotton is laid behind refractory brick.

- Q: Are sintered brick concrete bricks?

- Many kinds of brick, according to the raw materials used for clay brick, shale, coal gangue brick, fly ash brick, lime sand bricks and slag brick;According to the production process can be divided into sintered brick and non fired brick, in which non fired brick can be divided into compressed brick, steam brick and autoclaved brick;With or without holes, ordinary bricks, porous bricks and hollow bricks can be divided into ordinary bricks.

- Q: What are the main raw materials of refractory brick and runner brick?

- Category of refractory , runner brick mainly is clay brick

- Q: What to do if refractory bricks saltpeter when they are used outdoor

- Efflorescence is usually dialysised from brickwork joints, dealing with the gap is ok These white substaince inside the pan tile: Cement efflorescence efflorescence is wow cake section from light leather intestinal common disease inumiya Hua building surface, according to their different causes and manifestations, there is pan cream, white, whitening, cream, on the walls and decorative surface erosion and other names, is the change of soluble saline alkali soil, adobe, brick, cement, mortar, concrete, masonry, ceramic tile, paint and other building materials with temperature, humidity and other external environment, in a water absorption, water transfer, water evaporation process with physical and chemical changes of the original building material damage disease phenomenon, erosion degree also has the very big difference there is a common, get damp, foaming, powder, drum, hollowing, cracking, spalling, mildew and crystallization phenomenon. Cement efflorescence may have some relationship with the quality of the cement, sand, water, air, temperature, humidity, it is a common fault in building. Use cement to do the pebble shape, it also prones to the above problems: A layer of white stuff on the surface. Terms of settlement: Scrape the dust in brickwork joint, pointing again. Use special pointing agents, more resistant to corrosion, not easy to efflorescence.

- Q: The making process of clay brick

- Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks. In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q: Are buildings allowed to use red bricks?

- Is the red brick with clay, shale, coal gangue as raw materials, crushing, mixing kneading with artificial or mechanical pressing, sintering and building bricks after drying at 900 centigrade temperature by oxidizing flame firing. Also called clay brick. Red brick technical specifications are generally from 75 to 100. Ordinary fired brick (red brick) is also called standard brick. The size is 240*115*53. (mm) red colour, sometimes dark. Ordinary clay brick has a certain strength and durability, but also because of its porous and has a certain insulation, heat insulation, sound insulation and other advantages. Therefore, it is suitable for wall materials and masonry columns, arches, chimneys, floors and foundations. Old buildings use it as building materials. Invented by the Romans, many of the remaining classical structures in Europe had red brick and brick roofs and walls.

- Q: The boiler is divided into several categories according to the structure, what characteristics does each have?

- package boiler and assemble boiler are divided into vertical boiler and horizontal boiler. Vertical boiler. Assembled boiler adapts to boiler more than 6 tons, the package adapts to boiler less than 10 tons.

Send your message to us

LOW CREEP FIRECLAY CHECKER BRICKS FOR HOT BLAST FURNACE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords