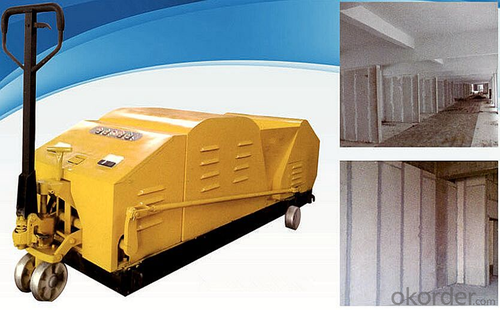

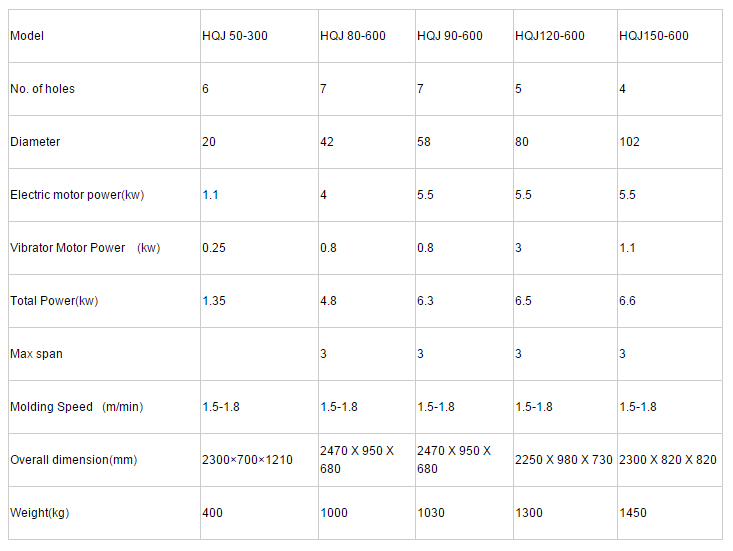

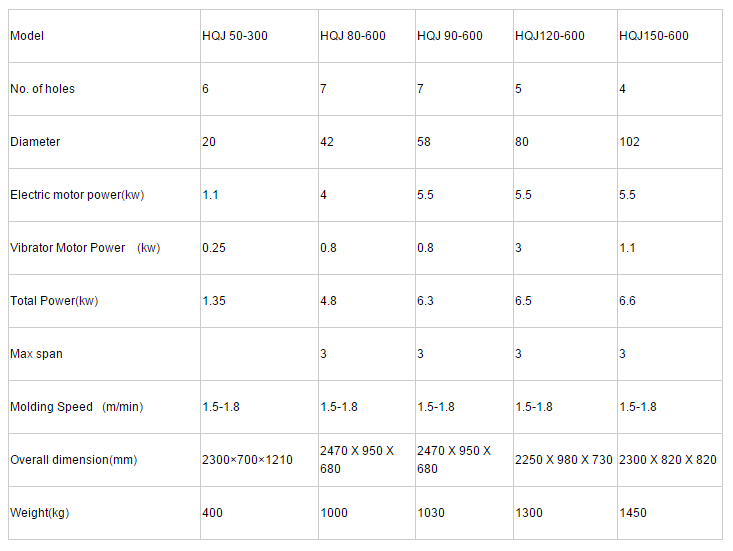

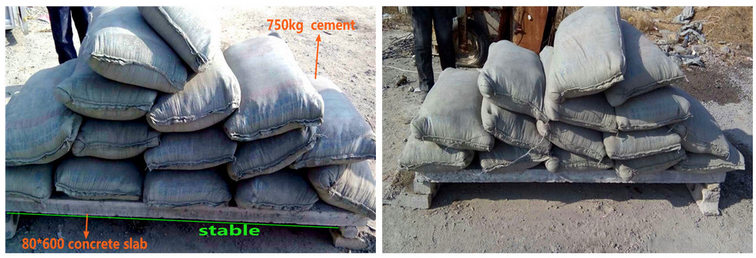

Lightweight concrete wall panel forming machine HQJ 80-600

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HQJ 80-600 Lightweight concrete wall panel forming machine

Quick Details

· Condition: New

· Application: prefab building

· Automatic Grade: Automatic

· Production Capacity: 60-70m/h

· Place of Origin: Shandong, China (Mainland)

· Brand Name: LING FENG

· Model Number: SL80*600

· Voltage: 360v

· Power(W): 4.5-8.0kw

· Dimension(L*W*H): 2.5*1.0*1.0m

· Weight: 2.0T

· Features: high efficiency

· Certification: ISO9001/CE

· Warranty: 12 months

· After-sales Service Provided: Engineers available to service machinery overseas

· Main frame: 2.0*1.4m

· Color steel thickness: 0.3-0.8 mm

· Insulation: first class

· Shaft axis: diameter 80

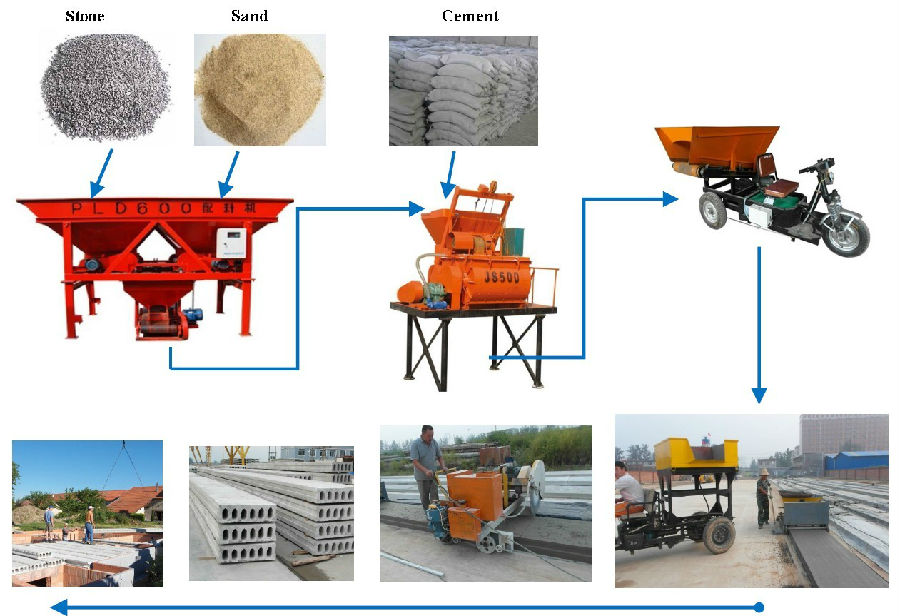

· Brick Raw Material: Cement, sand, stone.

· Strength: water proof, fireproof, sound proof

· Vibrator type: ZW type 3.0kw

· Motor model: YEZ132S-4-B5

· Color: yellow or custom

· OEM: available

Products

Quality

Packaging & Delivery

Packaging Details: Wooden case and wood flour into the bottom of the box.

Delivery Detail: Within 15 days

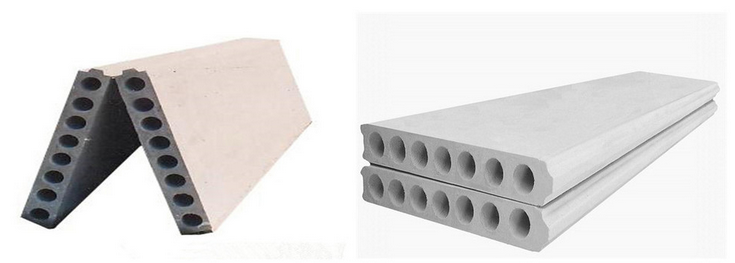

Major Parts and advantage of lightweight wall panel machine

Features:

I. Anti-corrosion and wear-resistant.

The machine frame is made of manganese steel whose quality is better than normal steel. The interior side of the mould is made of stainless steel (its thickness can be 2.2mm) which can stand repeated use and corrosive materials. It can be used for over 10 years. Besides, panels made by this kind of machine have better quality than other kinds. The panel will not be deformed. Its surface is smoother than others.

II. High capacity

Normal hollow core wall panel machine can make only ten panels in one mould, but this machine can make 14 panels at one time.

III. Energy-saving

The machine uses storage battery as power which can save a lot of electricity and is safe to use. Besides, if there is something wrong with the machine in the production line, it will not influence the use of other machines.

IV. Lower the cost of production

We use stainless steel for the mould instead of traditional steel. Steel mould machines need brushing de-molding agent or the panels can't be taken out. Stainless steel machines need a little de-molding agent, this can save both labor and material cost for manufacturers.

V. Hydraulic mould closing and opening

The mould is opened and closed by hydraulic. Its moving is very smooth and stable. All the four sides of the mould can be opened together, so it is very easy to use and it can save labor and cost.

VI. Unique design

We have special design not only for the single machine, but also for the whole production line. Our mixer can be customized for the customer according to their requirement. We also have special equipment to get rid of the dust so that the production is very clean.

Our Services

Interests in the good faith, interests in quality, interests in the service

Customer visits and technical guidance provides 24-hour service and lifetime maintenance services, supply of spare parts. Site church consumer operation, teach operating essentials, equipment maintenance and production experience, considerations.

Our factory can produce all kinds of equipment and prefabricated factory accessories according to customer demand.

Flow chart:

Other available machines:

- Q: I am writing a fantasy novel and part of it has to deal with farming and so I'd like to have a bit more information about low tech farming methods. Farming during the middle-ages and before the industrial revolution etc.

- You carried a scythe empty baskets w/ you into the field. Set the baskets down at one corner of the field, then walked a straight line away from the baskets swinging the scythe as you walked. When you turned around to walk back toward the baskets you stooped down used long lengths of wheat wrapped around the middle of an armful of wheat to bundle it into a sheath. You kept repeating this process until the field was harvested, then you put the sheaths into the baskets loaded the baskets into wagons to be driven to the grist mill to be ground. There were usually several people doing this in one field.

- Q: I wanna go into the woodwool or wood shredder manufacturing...plz tell where the machinery can b bought from? second hand m/c will also work........thnx a tonnn

- No body knows. Try google or craigslist or OKorder.

- Q: What subjects are specialized in mechanical manufacturing in secondary schools?

- [] [mechanical drawing machine design foundation [] [] engineering mechanical hydraulic and hydraulic transmission] [] "mechanical manufacturing technology of NC machining materials" "special processing" technology is still the main focuses on the operation, so there will be a variety of training etc.

- Q: What is a mechanical mouse?

- At present, the mouse on the market is divided into two major categories according to principle: one is mechanical mouse, and the other is photoelectric mouse. And now the wireless mouse. Mechanical mouse identification is very simple, the mouse flip over, if there is a small ball, it is a mechanical mouse.

- Q: Human capital refers to:Answerthe skills and knowledge that enable a worker to be productive.machinery used by labor in production.the accumulated financial wealth of households.physical capital owned by households rather than businesses.

- the skills and knowledge that enable a worker to be productive.

- Q: What kind of job is a mechanic in the end?

- Mechanical engineer is a person who works in a mechanical engineering field and has some experience and level. Mechanical engineers are generally divided into three levels, Junior Mechanical Engineer, intermediate mechanical engineer, senior mechanical engineer. The mechanical engineer is usually referred to as the three level of mechanical engineers, mechanical engineers can also refer to the intermediate.

- Q: methods of attaching condition monitoring of machinery?

- Your question is too vague to even attempt an answer. What type of machinery are you monitoring? What parameters of said machinery do you want to monitor - temperature, broken tool, air hydraulic pressure, motor current, vibration...etc., on and on. Please clarify what you are asking so that we can attempt to give you a reasonable answer.

- Q: Can anyone supply me with information on hydraulics and hydraulic machinery, it is for an engineering project, which involves lifting a heavy item and i would like to get information on hydraulics which can be used in this situation.

- how about a simple hydraulic floor jack

- Q: I want to know if someone can give me websites or something about places that sell modern machines for elaborating jewelry, ill like to know about a machine named stamping press for jewelry.. and if it is possible companies that sell machines for building jewelry in new york, or anywhere in the united states

- I would ask a jeweler.

- Q: i need info on the following machinery that were used in the WWIpics and videos are accepted as well bolt-action rifle machine guns artillery/ shells flamethrowers thanx !!!! :D

- World okorder /

Send your message to us

Lightweight concrete wall panel forming machine HQJ 80-600

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords