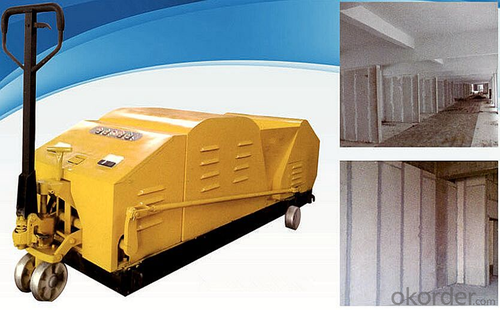

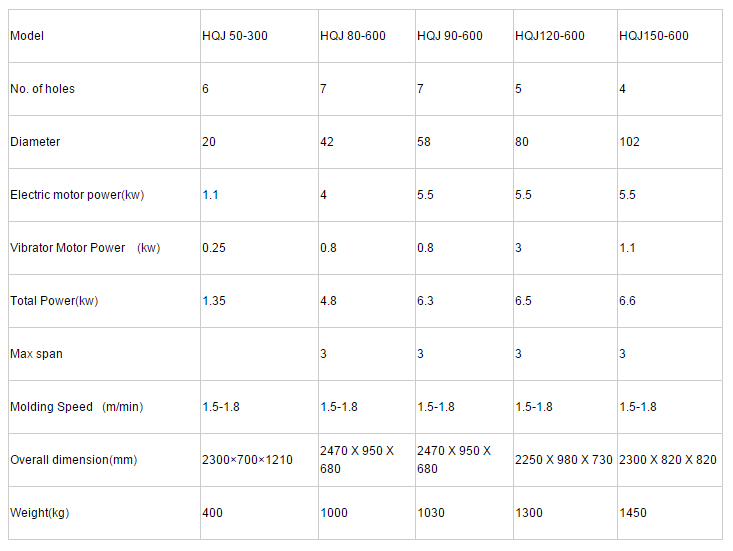

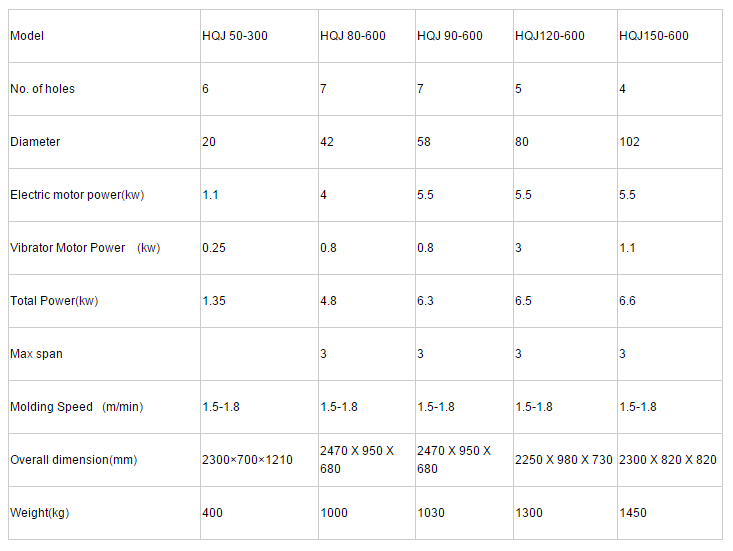

Lightweight concrete wall panel forming machine HQJ 50-300

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HQJ 50-300 Lightweight concrete wall panel forming machine

Quick Details

· Condition: New

· Application: prefab building

· Automatic Grade: Automatic

· Production Capacity: 60-70m/h

· Place of Origin: Shandong, China (Mainland)

· Brand Name: LING FENG

· Model Number: SL80*600

· Voltage: 360v

· Power(W): 4.5-8.0kw

· Dimension(L*W*H): 2.5*1.0*1.0m

· Weight: 2.0T

· Features: high efficiency

· Certification: ISO9001/CE

· Warranty: 12 months

· After-sales Service Provided: Engineers available to service machinery overseas

· Main frame: 2.0*1.4m

· Color steel thickness: 0.3-0.8 mm

· Insulation: first class

· Shaft axis: diameter 80

· Brick Raw Material: Cement, sand, stone.

· Strength: water proof, fireproof, sound proof

· Vibrator type: ZW type 3.0kw

· Motor model: YEZ132S-4-B5

· Color: yellow or custom

· OEM: available

Products

Quality

Packaging & Delivery

Packaging Details: Wooden case and wood flour into the bottom of the box.

Delivery Detail: Within 15 days

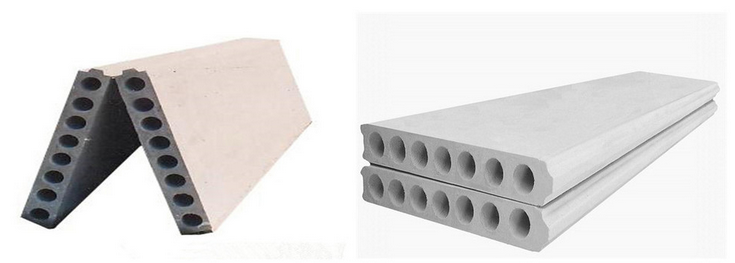

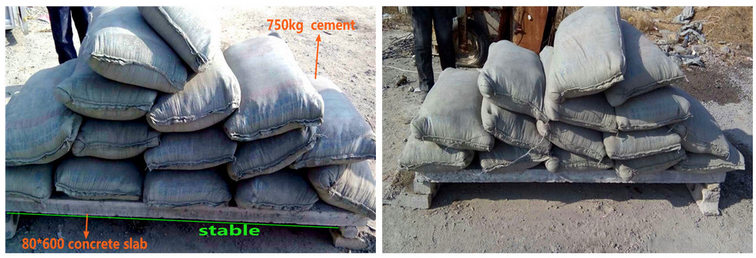

Major Parts and advantage of lightweight wall panel machine

Features:

I. Anti-corrosion and wear-resistant.

The machine frame is made of manganese steel whose quality is better than normal steel. The interior side of the mould is made of stainless steel (its thickness can be 2.2mm) which can stand repeated use and corrosive materials. It can be used for over 10 years. Besides, panels made by this kind of machine have better quality than other kinds. The panel will not be deformed. Its surface is smoother than others.

II. High capacity

Normal hollow core wall panel machine can make only ten panels in one mould, but this machine can make 14 panels at one time.

III. Energy-saving

The machine uses storage battery as power which can save a lot of electricity and is safe to use. Besides, if there is something wrong with the machine in the production line, it will not influence the use of other machines.

IV. Lower the cost of production

We use stainless steel for the mould instead of traditional steel. Steel mould machines need brushing de-molding agent or the panels can't be taken out. Stainless steel machines need a little de-molding agent, this can save both labor and material cost for manufacturers.

V. Hydraulic mould closing and opening

The mould is opened and closed by hydraulic. Its moving is very smooth and stable. All the four sides of the mould can be opened together, so it is very easy to use and it can save labor and cost.

VI. Unique design

We have special design not only for the single machine, but also for the whole production line. Our mixer can be customized for the customer according to their requirement. We also have special equipment to get rid of the dust so that the production is very clean.

Our Services

Interests in the good faith, interests in quality, interests in the service

Customer visits and technical guidance provides 24-hour service and lifetime maintenance services, supply of spare parts. Site church consumer operation, teach operating essentials, equipment maintenance and production experience, considerations.

Our factory can produce all kinds of equipment and prefabricated factory accessories according to customer demand.

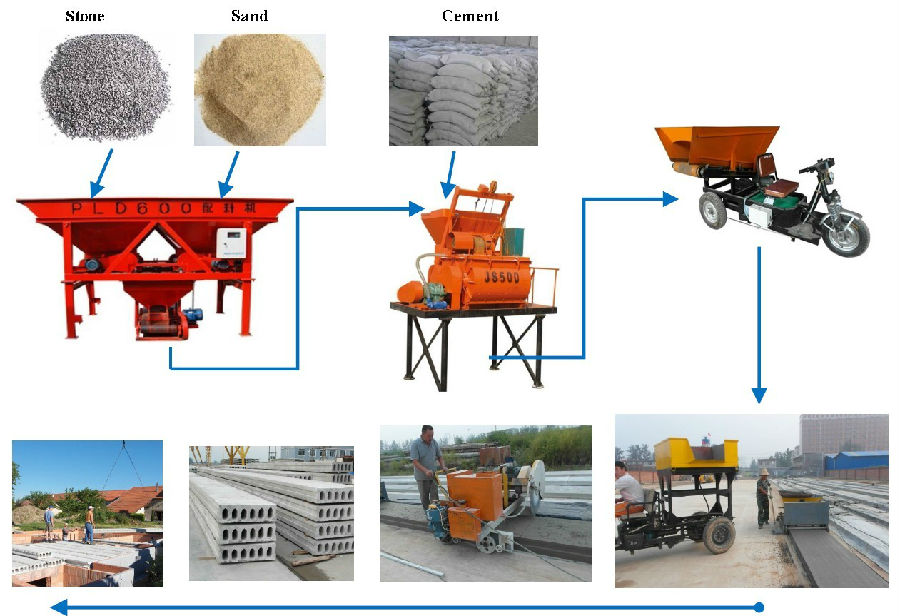

Flow chart:

Other available machines:

- Q: mechanic technician who can weld or bachelors in engineering? Or probably both right? I am a guy who is really into the hands on building of machinery, but I want to actually have a role in designing as well. I am really debating on going back to school for engineering or mechanics/welding. I am 34, work full time, and would only be able to go to school part time. I really want to get into a field where I am building, designing, and testing new machinery. HELP!!!

- You really should finish an Mechanical Engineers degree. If you don't do it now, you'll just wish you had in 5 years and by then you'd likely be done. All of the things you describe will require an engineering degree. Oh, BTW, ME's can make about 2-3X what a welder does. Astrobuf

- Q: Is the use of exercise machinery the best way to get fit?

- The use of fitness equipment such as elliptical, treadmills, weight training stations at the local gym are the best ways to improve your overall physical fitness. You can receive instructions on how to use the equipment by the Fitness Center monitors at your local gym. If you join a gym you will be amongst like-minded people. You may meet someone there who can become your gym partner and you both can give each other incentive to obtain physical fitness. You can also gain fitness with yoga and pilates to help with your flexibility. Zumba, Core and dancing classes can help with your cardio. These are suggestions but you must make the commitment to stay with your excercise program. Healthy eating habits, limiting alcoholic beverage consumption and not smoking tobacco products will help in your quest for physical fitness. It will not do you any good if you work out for three weeks and give up your fitness program. Oh, by the way, it will be beneficial to you if you have a complete check-up with your doctor before you start your lifetime practice of physical fitness. When you go to the gym you want to walk into the building under your own power. You do not want to be taken out of the building on a gurnee. It is very embarrasing and humiliating with people looking at you as you are wheeled out by paramedics, place in an ambulance and driven to a hospital. Good luck.

- Q: I want to lose weight but what methods work best on the stomach and hips area? I've heard doing aerobics was good but what exactly are aerobics?

- Okay first off, how old are you, you must be pretty young if you don't know what aerobics are. Aerobics is doing exercise that elevates your heart rate and makes your breathing rapid, and that is the secret, your breathing that is the fuel that burns calories. So really, you can do anything that will get you breathing in and out properly to increase your heart rate for at least 15 mins a day. What really works for me is running/jogging I have Tony Little's Gazelle it's great if used properly to elevate my heart rate. Crunches are great for your stomach and side leg lifts or kicks are great for those hips. Pilate's and Yoga are great and work really fast get you some easy beginner's tapes and do them regularly. Eat fresh fruits and veggies all day long cut out junk foods, but don't deprive yourself of anything, moderation is the key. Every 10 days go on a grape juice fast unsweetened of course it's really delicious. I promise you will not be hungry, this cleans out your system of toxins that clog you up build up fat deposits and rob you of your precious energy. Do some type of exercise daily, roller blading is great for the legs, just remember you have to always stay active for the rest of your life to stay fit, healthy and looking beautiful, so you have to be dedicated and not get discouraged, good luck and god bless.

- Q: In urgent need of blasting drilling team, only drilling, blasting, drilling machines come with, and other what the site

- 4, the subcontractor's (Professional) security emergency plan. 5, subcontract direction, provide all entry personnel roster, ID card copy, health certificate, and provide mechanical equipment acceptance record list and mechanical list. 6, the special construction organization design (program), including quality objectives and specific guarantee measures, and finished product protection measures, etc..

- Q: What's the name of that song with the music video of sexy girls in like...bikinis? Trampy clothing. They are like grinding up and down tractors and machinery. It's almost like mocking the shopping network or something. The girls are like, mechanics. They have goggles and everything. There were also bold colors. I don't remember much else about it. The song was techno, if I remember correctly.

- satisfaction- Benny Benassi

- Q: how i can access to free farm machinery manual in the internet?

- It okorder / Free! I doubt you will find anything especially if you are looking for tech info. the last one I bought about ten years ago cost me over ? 400 ( $800)

- Q: How many sub-sectors can be divided in the machinery industry?

- I okorder and hope you will find the information that you've been looking for. This may help you to get answer of your question. Wikimachine's mission is to organize information about machinery industry and make it useful for everyone. Machines are cool and extremely helpful, so shall be the information about machines.

- Q: Hi allI wonder if anyone out there has the answer to my question.My son got caught yesterday driving whilst on his mobile.. and yep he got caught by the police. He already has 9 points on his license so these 3 new points for using the mobile are going to automatically ban him for a year.He works as a ground worker and drives machinery ie: dumper truck and roller etcDoes anyone know if he can still drive the machinery???And ideas about how he may get off the 3 points.. can he take a course or something?Any ideas are gratefully accepted.Many thanks

- Not if he has to drive any of the equipment on public roads, because he won't have a license. The only way out is not to get those 3 points, and your only hope is a good attorney. It won't be cheap, but it will be better than losing his job.

- Q: Do you know how to operate heavy machinery?

- I can use the microwave.

Send your message to us

Lightweight concrete wall panel forming machine HQJ 50-300

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords