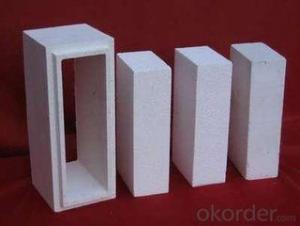

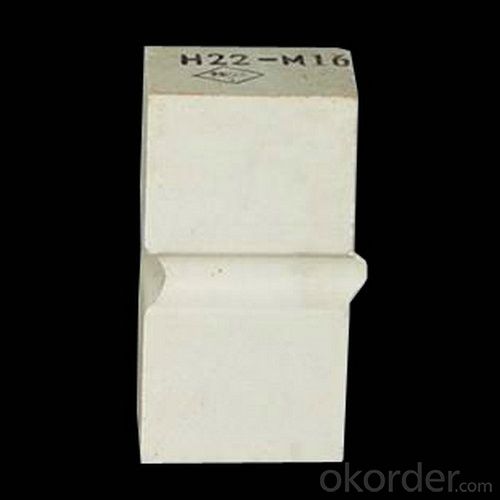

Corundum Brick - Light Weight Corundum Mullite Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Characteristics:

1. Low thermal conductivity

2. High strength and resistance to corrosion

3. Low heat capacity

4. Low content of impurities

5. High insulation

6. Excellent thermal shock resistance

7. Low density

Physical and chemical index:

Item/Type | JM-23 | JM -26 | JM -28 | JM -30 | JM -32 | |

Classification temperature, Reference using temperature (oC) ≥ | 1260 | 1430 | 1540 | 1650 | 1760 | |

Bulk density (g/cm3) | 0.8 | 0.9 | 0.9 | 1.0 | 1.25 | |

Crushing strength (Mpa) ≥ | 1.3 | 1.6 | 2.1 | 16 | 16 | |

Modulus of rupture (Mpa) ≥ | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

Permanent linear change (oCX24h)% ≤ | 1350°C×4h | 1400°C×24h | 1510°C×24h | 1620°C×24h | 1730°C×24h | |

Thermal conductivity (W/m.k) ≤ | 800oC | 0.18 | 0.31 | 0.32 | 0.44 | 0.50 |

1000oC | 0.2 | 0.34 | 0.35 | 0.45 | 0.52 | |

1200oC | - | 0.40 | 0.41 | 0.47 | 0.56 | |

Chemical Analysis (%) | Al2O3 ≥ | 37 | 58 | 67 | 73 | 77 |

Fe2O3 ≤ | 1.0 | 0.8 | 0.8 | 0.6 | 0.4 | |

Application:

Light Weight Corundum Mullite Insulation Brick can be widely used for lining or insulation layers of various industrial furnaces and kilns in metallurgical industry, machine building industry, ceramic industry, chemical industry.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets

- Q: What's the jade stove for?

- Is it a furnace made of corundum or a furnace for smelting corundum?Corundum brick stove is commonly used as a refractory material sintering furnace, can be fired refractoriness in refractories, below 1700 degrees such as brick, corundum brick, brick, alumina hollow ball and so on

- Q: Wave tile and throwing glaze, tile which good?

- These two tiles have their respective advantages and disadvantages, in fact, to say which kind of good, mainly depends on the decoration of personal preferences and the location of the shop. If it is only the shop wall, then design and pattern rich whole glazed tile is good, it can make the room impressive, improve decorative effect, make the decoration style to fit the characteristics of his personality. In addition, clean up is relatively easy, not easy to contaminated with oil stains and other pollutants. If it is laying floor tiles, tile Douglas suggested the use of tiles, tiles of good antiskid effect, water absorption rate is relatively low, so the kitchen toilet bathroom and other wet places is not easy to water seepage, improve the convenience of life.

- Q: How to improve the induction furnace campaign, from the promotion of refractory life start

- According to the workpiece, choose the appropriate hardware castable, corundum brick or refractory bricks, etc.

- Q: What refractory materials are used in industrial furnaces?

- Economically, it is necessary to do technical and economic analysis when selecting materials reasonably. Under the premise that the technical indexes agree with the working conditions of the furnace, the refractory materials with low quoted price should be used as much as possible, without high-grade finished products. To think about whether to make self (such as irrigation, refractory concrete) as far as possible to repair old.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- Do not know where the coking plant do dust treatment, processing conditions are different, the dust collector is not the same

- Q: What refractory materials are adopted in each part of the blast furnace?

- The furnace throat is a part of the direct impact and friction when the burden drops, and the high density and high alumina brick is usually adopted. The upper and middle shaft temperature is only 400~800 degrees, the parts with high alumina brick and sillimanite brick.

- Q: What is the hardness of corundum refractory bricks?

- Al2O3 containing more than 90% greater than the refractory brick called corundum refractory brick, also known as pure alumina refractory products. Corundum has a high hardness (9 Mohs hardness) and a high melting point. These are closely related to the firmness of the Al - 0 bond in the structure. Therefore, a-Al2O3 is the main phase of making high temperature refractory bricks and high temperature electrical insulating materials.

- Q: High temperature refractory material?

- Now the definition of refractory materials, has not only depends on whether the refractoriness at 1580 DEG. Refers to the current refractories used in metallurgy, petrochemical, cement, ceramics and other production equipment with inorganic non-metallic materials.

- Q: What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- Fused zirconia corundum refractory material of glass fiber kiln quantity is little, generally used in the kiln feed arch furnace flue, where large amount of places are currently using dense zirconium Zr, dense chromium

- Q: What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- Casting, casting mouth often appear shrinkage, brick porosity more, the density is lower, so in the brick wall of glass melting, the shrinkage in the kiln direction, if the nozzle outward, when the brick to erosion is very thin, can cause leakage of liquid glass accident. When the flame space is used in the upper part of the bath furnace, the service life is long, and the glass liquid problem can not happen, so the casting mouth is used outwards, and the service life is prolonged.

Send your message to us

Corundum Brick - Light Weight Corundum Mullite Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords