Laticrete Fiberglass Mesh Tape - 60g Fiber Glass Mesh Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Introduction

Fiberglass mesh, alkali resistant fiberglass mesh is on the basis of alkali-resistant or C-glass or E-glass woven fabric, then coated by acrylic acid copolymer liquid.

Characteristics: Good alkaline-resistance, high stength, excellent alkali and acid resistance, good cohesion, excellent in coating etc.

Uasge: It is widely used in wall reinforce, out side wall heat insulation, roof waterproof, reinforcement, plastic, bitumen, plaster, marble, mosaic. Etc. It is an ideal engineering material in construction.

Our best quality ablity:

1) mesh of warp and wet mesh is very straight

2)coating enough alkaline resistant glue and keep 60%-80% strength after testing in NaOH 28 days later

3)Made by C-glass or E glass fiber roving as basis material and then treated with acrylic acid coplolymer liquid.

4) our factory is the largerst fiberglass mesh manufacurer in China and the first Chiese factory which open fiberglass mesh factory in Dubai, UAE. In Chinese factory, there are more than 300 sets of textile machie and 8 sets of coating machines, every month we can produce more than 6000000 m2 fiberglass mesh. Dubai factory can produce more than 2000000 m2 every month

5) Dubai fiberglass mesh factory open in Dubai since 2012 year, no ant-dumping tax for europen countries, the quality can reach EU quality standard.

Specification:

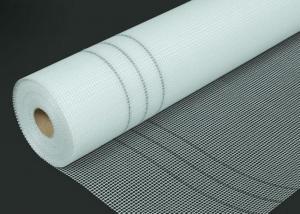

Weight: 45G/M2 --350G/M2

Weight: 45g/m2 3*3mm, 60g/m2 5*5mm, 60g/m2 3*3mm, 75g/m2 3*3mm, 80g/m2 5*5mm, 110g/m2 5*5mm, 110g/m2 10*10mm, 120g/m2 10*10mm, 130g/m2 5*5mm, 4*4mm, 145g/m2 4*4mm, 5*5mm, 4*5mm, 160g/m2 4*4mm, 4*5mm, 5*5mm, 190g/m2 4*4mm, 300g/m2 4*4mm, 400g/m2 4*4mm

Mesh size: 3*3mm, 4*4mm, 4*5mm, 5*5mm, 10*10mm

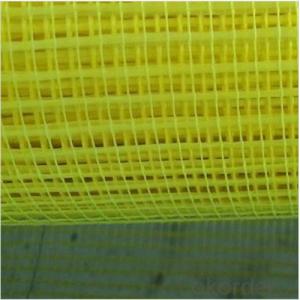

Color: White, blue, green, yellow, red

Width: 15cm --200cm

Roll length: 10m--500m

Fiberglass mesh, alkali resistant fiberglass mesh is on the basis of alkali-resistant or C-glass or E-glass woven fabric, then coated by acrylic acid copolymer liquid.

Characteristics: Good alkaline-resistance, high stength, excellent alkali and acid resistance, good cohesion, excellent in coating etc.

Uasge: It is widely used in wall reinforce, out side wall heat insulation, roof waterproof, reinforcement, plastic, bitumen, plaster, marble, mosaic. Etc. It is an ideal engineering material in construction.

Our best quality ablity:

1) mesh of warp and wet mesh is very straight

2)coating enough alkaline resistant glue and keep 60%-80% strength after testing in NaOH 28 days later

3)Made by C-glass or E glass fiber roving as basis material and then treated with acrylic acid coplolymer liquid.

4) our factory is the largerst fiberglass mesh manufacurer in China and the first Chiese factory which open fiberglass mesh factory in Dubai, UAE. In Chinese factory, there are more than 300 sets of textile machie and 8 sets of coating machines, every month we can produce more than 6000000 m2 fiberglass mesh. Dubai factory can produce more than 2000000 m2 every month

5) Dubai fiberglass mesh factory open in Dubai since 2012 year, no ant-dumping tax for europen countries, the quality can reach EU quality standard.

Specification:

Weight: 45G/M2 --350G/M2

Weight: 45g/m2 3*3mm, 60g/m2 5*5mm, 60g/m2 3*3mm, 75g/m2 3*3mm, 80g/m2 5*5mm, 110g/m2 5*5mm, 110g/m2 10*10mm, 120g/m2 10*10mm, 130g/m2 5*5mm, 4*4mm, 145g/m2 4*4mm, 5*5mm, 4*5mm, 160g/m2 4*4mm, 4*5mm, 5*5mm, 190g/m2 4*4mm, 300g/m2 4*4mm, 400g/m2 4*4mm

Mesh size: 3*3mm, 4*4mm, 4*5mm, 5*5mm, 10*10mm

Color: White, blue, green, yellow, red

Width: 15cm --200cm

Roll length: 10m--500m

Package:

Inner packing: Plastic bag or shrink film

Outer packing: Export carton or pallet

- Q: In what circumstances do you need to paste the mesh, if not, it is okay?

- The mesh can be used for moisturizing or thermal insulation on the wall, mesh is also an important advertisement material, which can effectively avoid the tension contraction and cracking caused by external forces of whole surface in the plastering layer, and thin mesh is often used in refurbishment of wall and interior wall insulation.

- Q: The difference between glass fiber and carbon fiber

- The glass steel curing temperature of glass fiber is not very clear, the curing temperature of carbon fiber products is not determined, generally the higher the temperature curing speed, curing speed at room temperature is relatively slow, so if you need to speed up the curing speed, and temperature in the heating box can be placed in the concrete temperature control, you still want to go to check the information and practical operation.

- Q: How to flang external wall insulation alkali-resistant mesh in window and door? ?

- Wrapping window with insulation board mesh is easy to crack. In order to prevent cracks, the window needs a shear. And pay attention to the sequence of boards. The corner should be cut into knife shape. Do not let the joint fissure be in the window corner, and this is the insulation regulation. Although it will increase costs, it will prevent accidents and maintenance.

- Q: Interior wall laying fiber mesh cloth, what matters should pay attention to plastering? Is it not allowed to lap when laying mesh cloth?

- Before construction, do a good job of watering walls, wet and beat, the fiber network overlap of not less than 100mm, the corner of the door should be laid, so that the grid is not exposed.

- Q: what's the specification of the external wall thermal insulation mesh?

- The mesh of interior wall is made of glass fiber as the main raw material and the tensile strength resistance is better when used in the exterior wall, and the number of applied grams is not the same, but it is also made through the process of multi-channel, the external wall thermal insulation mesh is generally 80-160 g, quality anti-tensile strength is relatively small, usually about 50-60 grams. the unit weight of interior wall thermal insulation mesh will be generally lighter. The interior wall of this mesh is the ideal material of grc wallboard.

- Q: How to paste glass fiber gridding cloth on the walls?

- It is recommended to use white glue mixing with 801 glue, or batch embed glass fiber gridding cloth with some talcum powder. The price for the latter is 5 yuan/㎡.

- Q: What's the material of wall gridding cloth?

- Wall gridding cloth, also called glass fiber wall gridding cloth or alkali resistant glass fiber, is made of yarn raw material, by coating with acrylic copolymer solution and then drying. Gridding cloth for external walls is featured by low cost, messy layout, high resistance to alkali, corrosion and cracking, easy construction. It is a new construction material used for strengthening cement plaster wall, crack resistance and thermal insulation of external wall.

- Q: Where to buy Lufeng glass fiber gridding cloth?

- this product has very good stability. The glass fiber gridding cloth for internal walls uses glass fiber as main material. From value perspective, nearly thirty percent of the gridding cloth for external walls uses middle-alkali or alkali-free gridding yarn as raw materials. Then it is used for increasing tension between the cement and building walls.

- Q: What are the construction technologies of the thermal insulation material Mesh?

- 1. The material preparation: Polystyrene foam board, the special adhesives, one-component polymer mortar, alkali-resistant fiberglass mesh, plastic bolt up, polystyrene foam rods and water. 2. The tool preparation: Electric wire cutter or wallpaper knife, handsaw, ink fountain, 2m guiding ruler, ruler, wood beam, tape, motor stirrer, trowel, internal and external corners small brush, the plastic mixing bucket, the raw emery paper, 2m power board 3. The technological process: The first step: With the special sticky adhesive pre-turning bag mesh. The second step: The stick polyphenyl insulation board. The third step: The drilling and fastener installation Step Four: The grinding and leveling of the surface of the insulation board. Step five: The polymer mortar. Step Six: The polymer mortar of the ground floor. Step Seven: The buried quote Mesh Step eight: The plastering layer polymer mortar Step 9: Acceptance

- Q: What consequence will using non-alkali resistant fiberglass mesh cause in thermal insulation construction?

- Current thermal insulation materials are alkaline, and concrete is also alkaline. Do you hear about acidic concrete? So I think you would know the consequence.

Send your message to us

Laticrete Fiberglass Mesh Tape - 60g Fiber Glass Mesh Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords