Plastic Sheets - Latest ABS Plastic Sheet 0.8mm Thick for Model Materials and Architectural Model Materials

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Latest abs plastic sheet 0.8mm thick

Product Introduction

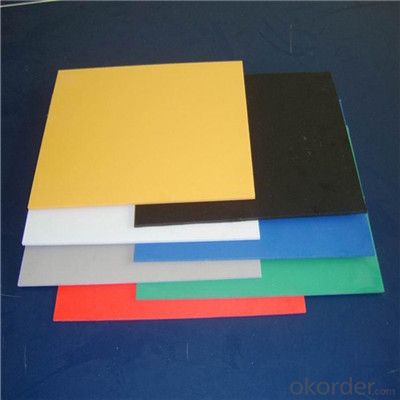

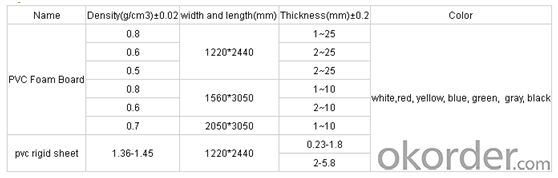

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

Product Uses

1 mm- 5 mm: suitable for advertising supplies, electronic instrument, packaging

15 mm -20 mm: suitable for furniture

10 mm -20 mm: suitable for bath cabinet, cabinets

5 mm- 20 mm: exhibition board, indoor and outdoor decorative plate (different customers have different requirements)

3 mm coated :bus interior ceiling

Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

- Q: This Halloween, I plan to build a very small haunted house in the front of my house.I need to know how to build the cheapest, easiest, walls possible. I plan to make this haunted house on the concrete portion of my front yard (right by door) with a little bit of the entrance on the grass. I plan on using plastic sheeting but I don't know how to connect them. somebody told me to put PVC pipes in paint buckets and add cement to the bucket. then connect the walls with the plastic sheeting. another told me to stab PVC/plywood into the ground but in doing most of it on concrete. so basically, what's the cheapest and easiest way to build walls on concrete AND grass? please also tell me how to build it, I'm a young kid with no construction experience and no money.

- You need a few of the cardboard boxes that refrigerators come in. Connect them together with duct tape. Cut doors windows etc.

- Q: Are plastic sheets resistant to discoloration from humidity?

- No, plastic sheets are not completely resistant to discoloration from humidity.

- Q: What glue is the adhesive between aluminum and plastic in aluminum-plastic plate?

- Shanghai state is committed to polymer materials research and development and production for more than 20 years, China sold in the state as many as 200 kinds of products, has the most advanced production lines and first-class testing equipment. The main products include flame retardant and anti-static coal pipe special materials, flame retardant and anti-static masterbatch, coal pipe flame retardant masterbatch, antistatic masterbatch, resin adhesive extrusion, graft copolymer, ionic polymer, mainly used in mining pipe and anticorrosion steel pipe, steel plastic composite pipe, PE pipe, steel wire spiral rib reinforced PE pipe, composite plate, composite film etc..

- Q: What's the difference between memory plastic and sheet metal?

- 1, light weight: about half with plate weight, half nylon material 85%, reduce bridge nose, ear burden, make wear more comfortable and comfortable2, bright colors: more colorful than ordinary plastic frame color3, resistance to impact: nylon material 2 times ISO180/IC:>125kg/m2 elastic effect, to prevent the impact of eye damage4, high temperature: 350 degrees high temperature resistant short ISO527: anti deformation index 620kg/cm2 melt combustion frame deformation discoloration make frames to wear more5. Safety: the release of residues meets the requirements of European food grade materialsTR90 material is more expensive than its PCCP and other frame materials, and the manufacturing process is more stringent, the TR90 frame price is several times more expensive than it

- Q: Sometimes when there is heavy rain, water seeps into the basement through cracks in the walls and floor. We do have french drains and a sump pump. We tried to place plastic sheeting along one side of the house. Previously, there was some green algae growing on that side. Now the entire side is covered in green algae. What should we do?

- I strongly agree with previous answer. Water vapour will condense on plastic and this will bring mould. Your french drains may need clearing out, they do get full of sediment, maybe you could use bigger size aggregate for better drainage ? Also make sure the basement is well ventilated with air bricks, perhaps you could get more fitted so there is a better air flow. If you already have enough air bricks, make sure they are not clogged up with dust, spider webs etc.

- Q: Are plastic sheets resistant to bending during installation?

- Yes, plastic sheets are generally resistant to bending during installation. They are designed to be flexible and durable, allowing for easy handling and installation without breaking or deforming.

- Q: I have purchased a plastic sheets (similar to the office cair mate ) to put it on the carpet (only on the walk-way). But I don't know (the best way) how do I stick the plastic sheet to the carpet ?. Please help.I have used the packing tape to stick it together. It doesn't work well. Please help

- if you bought the right kind it should have lil things like on the bottom of soccer shoes so that it adheres to the carpet

- Q: Can plastic sheets be used for outdoor furniture?

- Yes, plastic sheets can be used for outdoor furniture. They are resistant to weather conditions, durable, and easy to clean, making them a popular choice for outdoor applications.

- Q: What are the most common applications for plastic sheets?

- Plastic sheets have a wide range of applications, but some of the most common ones include packaging materials, construction and building materials, automotive components, signage, displays, protective barriers, and various household and consumer products.

- Q: These sheets should be non-transparent, pure white, 4-6mil in thickness, and relatively stiff (not like that used for plastic bags, but rather like mylar sheet).

- Most hobby shops should be able to supply you with this type of material. If they do not have it then they should be able to locate a supplier for you or at least get you a catalog that would allow you to purchase modeling materials. The link below is for a company that sells many plastic sheets and scaled plastic structural members for railroad models and that type of thing. Send for that catalog.

Send your message to us

Plastic Sheets - Latest ABS Plastic Sheet 0.8mm Thick for Model Materials and Architectural Model Materials

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords