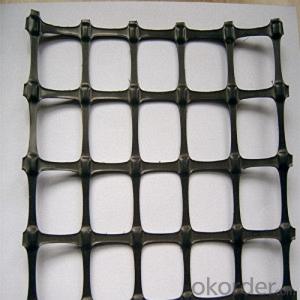

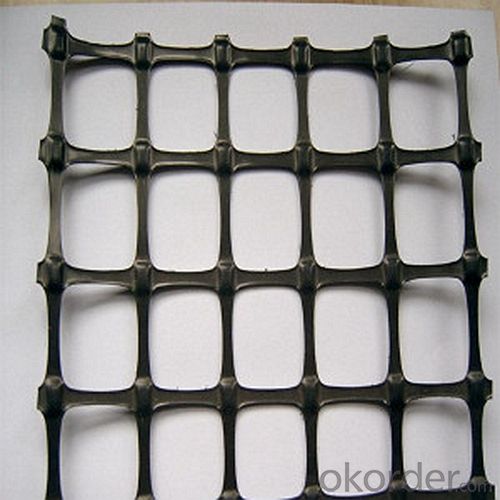

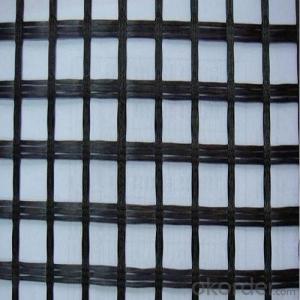

Landscaping Geotextile - Fiberglass Geogrid with Low Elongation and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid features

1. Light weight, high tensile strength, high modulus, low elongation and good

toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Packaging & Shipping

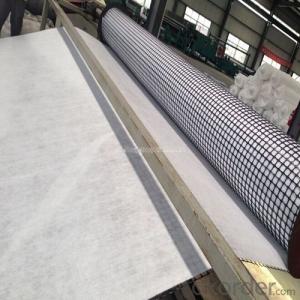

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

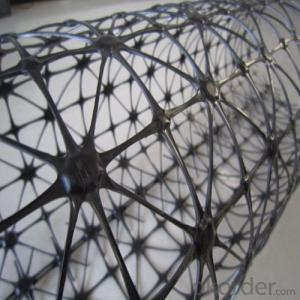

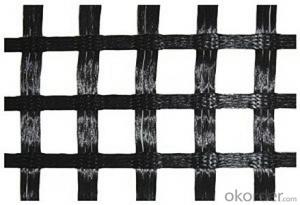

A: Yes, please check the pictures:

- Q: Geotextile geotextile geotextile construction geotextile specific application

- Geotextile is a large number of textile materials used in civil engineering in recent years, geotextile, with excellent isolation, filtration, drainage, reinforcement, protection, closed and other functions. Geotextile, is widely used in highways, railway subgrade, airport runway, river bed, dam construction and reclamation, flood control and other major projects. Geotextile use: water conservancy construction: seawall, river embankment, lake embankment project; reservoir reinforcement project; beach reclamation project; flood control. Transportation engineering: soft foundation reinforcement treatment; slope protection; drainage system; green isolation zone. Power plant construction: nuclear power plant base, thermal ash dam, hydropower station and other projects. Port waterway works: port terminals, locks, waterway management and other projects. Other works: tunnel, subway, construction, tailings treatment; landfill and other projects

- Q: How do geotextiles affect soil consolidation?

- Geotextiles have a positive impact on soil consolidation as they provide reinforcement and stabilization. By acting as a barrier, they prevent the mixing of different soil layers, reducing the potential for settlement and increasing the overall strength of the soil. This consolidation is achieved through the interlocking of geotextile fibers with the soil particles, enhancing the load-bearing capacity and preventing the loss of fine particles.

- Q: How do geotextiles reduce construction time and cost?

- Geotextiles reduce construction time and cost by providing various benefits such as soil stabilization, erosion control, and drainage improvement. They act as a barrier against soil erosion and help in retaining the structural integrity of the construction site. By preventing the need for extensive excavation and grading, geotextiles minimize construction time and reduce the cost associated with labor, machinery, and materials. Additionally, they enhance the overall performance and longevity of the project, ultimately saving both time and money in the long run.

- Q: Can geotextiles be used in coastal protection projects?

- Yes, geotextiles can be used in coastal protection projects. Geotextiles are commonly used as erosion control measures in coastal areas. They can help stabilize soil, prevent erosion, and enhance the overall resilience of coastal structures. Additionally, geotextiles can provide a protective barrier against wave action and filter out sediment, making them an effective solution for coastal protection projects.

- Q: What are the disadvantages of using geotextiles?

- One of the main disadvantages of using geotextiles is their potential for clogging and reduced permeability. Over time, fine particles and debris can accumulate within the geotextile, leading to reduced water flow and drainage. Additionally, improper installation or lack of maintenance can cause geotextiles to shift or tear, compromising their effectiveness. Moreover, geotextiles may not be suitable for all soil conditions or applications, as they may not provide adequate stability or strength in certain situations.

- Q: Is there a coinage between the embedded pipeline and the gravel blind ditch? Also on the backfill plant how to set the quota? Also ask the master advise! More

- You can go to the civil online forum to ask questions, there are a little more professional.

- Q: Can geotextiles be used in geogrid reinforced retaining walls?

- Yes, geotextiles can be used in geogrid reinforced retaining walls. Geotextiles are often used as a separation and filtration layer between the backfill material and the geogrid reinforcement in these types of walls. They help to prevent the mixing of different soil layers, enhance drainage, and improve the overall stability and performance of the retaining wall system.

- Q: What are the design considerations for geotextile-reinforced slopes?

- Some key design considerations for geotextile-reinforced slopes include selecting the appropriate type and strength of geotextile, considering the slope angle and height, evaluating the soil conditions and stability, determining the required length and spacing of reinforcement layers, ensuring proper installation and quality control, and accounting for factors such as water drainage and vegetation establishment. Additionally, the design should consider the long-term durability and maintenance requirements of the reinforced slope.

- Q: How do geotextiles contribute to the environmental sustainability of construction projects?

- Geotextiles contribute to the environmental sustainability of construction projects in various ways. Firstly, they help in soil stabilization by preventing erosion and promoting vegetation growth, thereby preserving the natural landscape and reducing the need for costly erosion control measures. Secondly, geotextiles can act as a filter, allowing water to pass through while trapping harmful pollutants, thus protecting surrounding water bodies from contamination. Additionally, they enhance the durability and lifespan of structures by providing reinforcement and reducing the need for excessive maintenance or repairs. Overall, geotextiles play a crucial role in minimizing the environmental impact of construction activities and promoting long-term sustainability.

- Q: It is good to cover the geotextile

- What are you breeding? Tarpaulin can be waterproof and waterproof, do not know if you have not seen geotextiles, geotextiles and silk cotton coat inside the like, light, there is a certain role in insulation, but not waterproof. Hope to help you

Send your message to us

Landscaping Geotextile - Fiberglass Geogrid with Low Elongation and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords