Fixing Type Truck Unloading Platform for Bulk

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

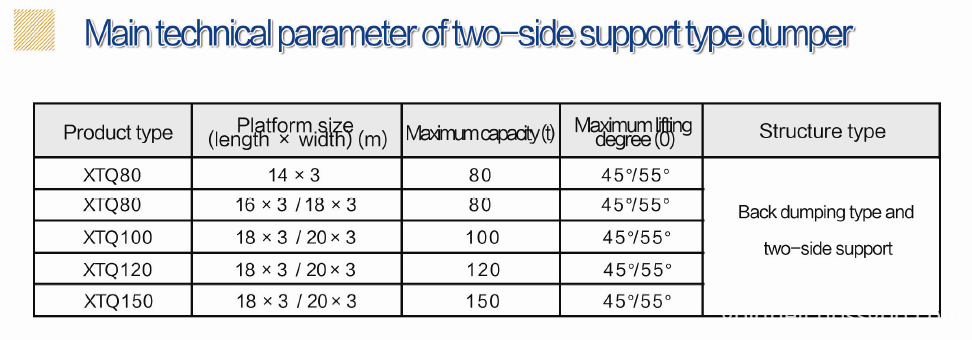

XTQ series truck unloading platform is truck bulk material unloading device that integrates electric and hydraulic control, and is widely used for bulk materials like grain, forage, cement and coke. The equipment improves production efficiency, saves unloading cost, and creates good economic benefit for the user.

Our company starts to design and produce truck unloading platform since 1990's, and now is the largest manufacturer of that in China, that has the largest market share in China. Our company is the only drafter of national standard of truck unloading platform GB/T 21489-2008 [Bulk Grain Truck Unloading Device". The product is exported to various countries and areas such as Japan, Vietnam, Malaysia, Thailand and India.

Truck unloading platform is suitable for automatic unloading of bulk materials like grain, forage, cement and coke, and can be used in industries of chemical, metallurgy, mining, port and coal.

Truck unloading platform mainly consists of dumping platform, wheel blocking mechanism, main hydraulic oil cylinder, wheel stopper, hydraulic control system, and electric control system.

Our company also produces load cell, strain gauge, weighing indicator and scales such as truck scale, platform scale and hopper scale.

- Q: Talk about how to cut the cost of moving materials.

- I think the main thing is to choose a range of suitable devices. If the moving objects and routes are relatively fixed, the use of the manipulator can be more efficient. The cost is naturally reduced.

- Q: What is the rational and scientific classification of logistics facilities and equipment

- Facilities: like warehouses, roads, public parking lots and so on. Equipment: vehicles, pallets, forklifts, RF scanners, GPS locators, and so on. Large and long-term use and investment, not easy to move and sell are facilities.

- Q: The wear-resisting parts in the broken machine are mainly the direct contact with the material

- There is a need to contact, the crusher is a lot of model and the performance is different. For example: the jaw is broken, the hammer is broken, the fight is broken, the cone is broken... It is. Wear-resisting material is different also, also need according to the material hardness, strength of the material that is broken, the choice is ok. Materials: alloy white iron (high chromium cast iron), high manganese steel, alloy steel (high, medium, low carbon and alloy)... It is. It's best to find experienced manufacturers. Hope to adopt.

- Q: The development of material handling

- Domestic market competition is the basic material handling machinery, high-end market is mainly composed of multinational companies, domestic key large enterprise also had some markets in some specific fields; The participants in the mid-market market include large enterprises in China and small and medium-sized enterprises with excellent manufacturing technology and high management level. Many of the small scale, poor technology, poor management, lack of product innovation of enterprise, product quality is not high, low added value, poor economic benefit, in the industry of low-end market, competition is intense. "Twelfth five-year" period to 2020, is China's national economy sustainable development strategy implement and promote the development of circular economy, take a new road to industrialization, the basis for building a resource-conserving and environment-friendly society an important period. Attaches great importance to the society and the enterprise logistics role, vigorously develop modern logistics industry, to promote the development of and promote industry, improve the quality and efficiency of economic operation, enhance the comprehensive national strength and the enterprise competitiveness, has the very vital significance. It is an effective means of carrier for all walks of life of the national economy, including the manufacturing of material handling equipment which supplies the large amount of equipment needed for the second and third industries. The rapid and steady development of the national economy, the informationization and industrialization of the basic industries, provide the best opportunities for the manufacturing industry of materials handling equipment.

- Q: What is the material handling and handling equipment?

- ?The shelf storage system Pallet racking | cantilevered shelves shelves | | gravity type rotary rack | pick racking system 4. Automated multi-layered storehouse stacker | | stacking robot horizontal rotary automatic vertical type rotary library | automatic library | tray type automatic library 5. Cold chain equipment Refrigerator car | | cooler cold box | | 6. Other refrigerator storage site finishing equipment workshop equipment | turnover box | flexible bar | | plastic cage car truck 7. Bar code identification system data acquisition equipment | radio frequency identification (RFID) system | data terminals

- Q: The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q: Material handling system in the factory

- The machinery factory's internal logistics system involves the production plan, process flow, moving operation, warehouse management, information system and so on.

- Q: The principle of material handling

- Planning principles: plan all material handling and storage activities to achieve maximum overall operational efficiency. 2, the principle of system, to integrate various handling activities and suppliers, purchase, storage, production, testing, packaging, storage management, shipping, transportation, and the customer's operating system as a whole.

- Q: What is the carrying equipment of the container cargo

- Shockproof and vacuum packaging, equipment hoisting, lower layer, translation, adjustment level, container (container), import crane, forklift professional service.

- Q: What are the requirements for the science of loading and unloading

- Reduce the load ratio of the mobile carrying equipment. To optimize the utilization rate of transportation equipment and manpower. Plan all the equipment to be maintained and maintained regularly. When there are more efficient means of handling and equipment, it should replace obsolete methods and equipment.

Send your message to us

Fixing Type Truck Unloading Platform for Bulk

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords