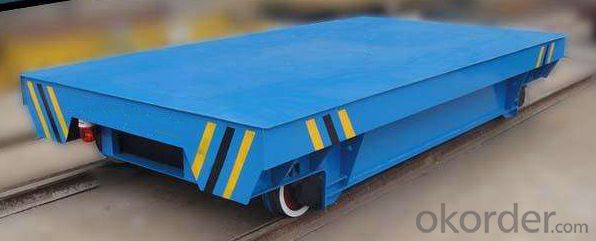

Electric Flat Car,Electric Rail Car,Trolley

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

Electric flat car is an electric rail transport vehicle.Also known as trolley, cross vehicle.It has the advantages of simple structure, convenient use, easy maintenance, large bearing capacity, less pollution and so on.Widely used in machinery manufacturing and metallurgy factory, as the workshop internal coordination crane transport heavy cross in.

Technical Parameters

The most of electric flat car is reel power supply for electric flat car, with a cable reel 380V AC power supply.Cable reel for hysteresis coupling, ensure the uniform stress of the cable is not easy bad.The exchange of 380V to flatcar YZ metallurgy Lifting motor provides power, electric flat car operation.Flat car running cable reel automatic cable rolled up or release, by the reel power supply length effects, general maximum operating distance is less than 200m. The single-phase 36V (three-phase) low-voltage track power supply electric flat car, rail sliding contact line power supply.Ground step-down transformer control cabinet (three-phase AC single-phase) 380V buck to single phase (phase 36V), via rail sliding contact line is fed to a flat car, the car a step-up transformer for single phase (phase 380V) AC.For flat cars in single phase capacitor motor provides power (three YZ metallurgy Lifting motor).Because there is no cable, it is safe and reliable, not afraid of hot, not hit, do not prevent cross transport, easy to realize the remote control and automation, transportation arrangement with great convenience to the factory.But the track construction requirements higher, should ensure that the track insulation, over a certain distance running track should be added to copper compensation line.Running distance is longer also need to increase the number of voltage transformer.

The electric flat car starting through the track starting current is very large (up to 1000A), at the end of the track has a large voltage drop, caused by single phase capacitor motor starting difficulty, the single-phase flatcar maximum tonnage is 50 tons, load 50 tons and above using three-phase 3

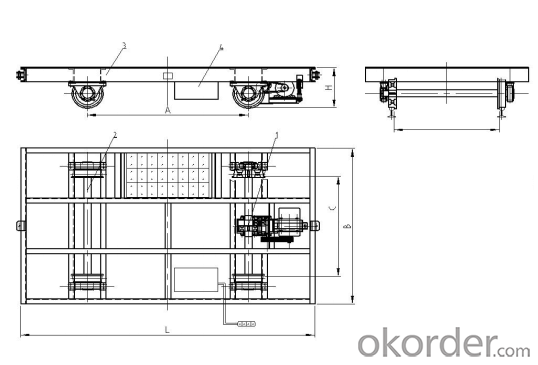

Structure

-General

The electric flat car mainly consist of frame, transmission device (active, passive wheel wheel), electrical control.

Frame with four longitudinal beams and a plurality of beams and decking plate welded into a frame structure, usually with large steel as frame longitudinal beam, bearing frame, take eight, uniform stress.Wheel-set on the shoulder pole bearing seat is connected with the frame by bolts, the structure effectively reduces the height of table.

Gear reducer cycloidal type gear reducer on the flat end, convenient assembly and maintenance, convenient refit.

Electric flat car and set up a connection hook, when necessary, can draw other cars or be towed.Flat car for lifting the lifting holes arranged on both sides.Mode of operation for the use of a hand held button box walking vehicle control.

-Wheel

The wheel and axle of the electric flat car is arranged between the inner and outer insulating sleeve and the insulating pad, the insulating sleeve with high mechanical properties of insulating materials made from nylon, wheel after insulation makes the electric flat car can use two tracks as a two conductor rail.Axle material for the 45 # steel quenched and tempered, wheel material using 55 high quality steel, surface quenching, bearings are double-row spherical roller bearings, can automatically compensate the deformation of frame error.

Wheel bearing seat through the pole mounted on the frame, each side with four fixing bolt, the structure effectively reduces the height, lateral stability, bearing capacity, stress of a frame beneficial.

-Transmission Device

The transmission form of the electric flat car as a V belt deceleration with a two gear reducer.The motor through a triangular V belt transmission two stage gear reducer, reducer high speed motor is fixed on the body side, by tension bolt and tension belt.

Speed reducer for flat car special axle-hung hardened-gear speed reducer, the output shaft is driving wheel axle, gear for hardened gear, has the advantages of small volume, large transmission power, good fatigue strength.Gear material pinion 40 Cr, 20Cr.Speed reducer and the driving wheel set is composed of a transmission device assembly.Through the pole bearing block is mounted on the frame, each side with four bolts to fix.

-Traction Hook

Electric flat car and set up a connection hook, when necessary, can draw other cars or be towed.Pay special attention to when the car is towed, be sure to lift the brake, to prevent gear or triangle V belt damage.And do not exceed the rated speed of flat, otherwise the motor for super rotation state which could damage.

- Q: What is the proof of working in mechanical design?

- Outline first Ⅲ part, is to the qualification examination examination form, time, attention, and the structure of test paper, test question distribution, topic topic quantity, and degree of difficulty of related regulations and instructions.

- Q: What is a forklift? Forklifts are special equipment

- Forklift truck is an industrial transport vehicle, which is a variety of wheeled transport vehicles for loading and unloading, stacking and short-range transportation. International standardization organization ISO/TC110 is called an industrial vehicle. Often used for the transportation of large items in storage, usually with a fuel engine or battery. It's a special equipment.

- Q: The wear-resisting parts in the broken machine are mainly the direct contact with the material

- The production plants of anti-wear materials are found all over the country, so that it is better to take the nearest, or increase the freight and increase the cost. It's not realistic to buy things at a low price. Where are you, the specific manufacturer can search on the Internet.

- Q: Why should we emphasize unitization and standardization in material handling

- Reducing the degree of climate impact, ensuring normal work, accelerating the flow of goods and improving efficiency. 1) logistics base module The logistics base modulus is the minimum size of the standard size of the logistics system. In basic module size was determined, the size of the various specific standards, should be based on basic module size, select the integer times to the prescribed standards for size, foundation modulus size is determined, just a standard size in multiple choice, it can be used as a standard of other size.

- Q: What is the material handling and handling equipment?

- . Highway transportation equipment Heavy tractor semi-trailer | van | | equipment | special transportation vehicle 9. Warehouse peripheral devices cllimbing trolley | slide machine loading and unloading platform | | | industrial door platform loading and unloading of rain loose 10. | | tray container unit equipment container bags | container net | slide 11. Forklift handling vehicle | electric flat car | | tractor attachments of ft | forklift parts 12. Manual handling equipment Hydraulic pallet truck cart hydraulic pallet stacker | | | lever type hydraulic lifting flat wagon | push car 13. Automatic sorting system, automatic sorting machine | | automatic sorting conveyor system automatic control systems and equipment

- Q: Urgent, please go to logistics expert, the question about the warehouse

- For a long time, China in the pharmaceutical management system, technology innovation ability etc. There are many problems, the development of Chinese medicine of excessive development costs, product production and marketing costs, the price is expensive. And in the international medical market, due to some countries have adopted advanced technology and equipment, leading technology level and first-class management experience, reduce medical costs, market prices to fall. Has always been a high tariff on foreign pharmaceuticals in China, and set the non-tariff barriers, therefore, cheap international medicine market is difficult to form in Chinese medical market, the price of this kind of situation can't meet the increasing our people's consumption level and the aging of the population.

- Q: The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q: Material handling system in the factory

- The machinery factory's internal logistics system involves the production plan, process flow, moving operation, warehouse management, information system and so on.

- Q: What is the relevant content of the flow of materials, storage and usage

- The transport system, the choice of carrying technology and equipment. To some extent determine the distribution and operation of the production logistics system. And the efficiency, complexity, size and economic effect of the production system are very strong. The important problem in production logistics is choosing the right transport equipment. These devices should be able to adapt to the nature, weight, shape, size and material flow of the moving material. We need to keep the fixed investment of the equipment low, and we need to meet the demand for moving. There are several kinds of moving, intermittent, and round-trip, which are divided into horizontal, oblique, vertical or two-dimensional direction. Other transport requirements include: channel flow shunt, location stop, high-speed moving, product placement, etc. Also consider moving objects and environments such as forming, powder, drying environment and cleaning environment. Finally, the mode of carrying, the combination of the equipment and the quantity of the specification are determined. The speed requirements of the transport are based on the production beat.

- Q: What is the carrying equipment of the container cargo

- Shockproof and vacuum packaging, equipment hoisting, lower layer, translation, adjustment level, container (container), import crane, forklift professional service.

Send your message to us

Electric Flat Car,Electric Rail Car,Trolley

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords