Kwikstage System Scaffolding with Steel Q235 Q345 CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Kwikstage System Scaffolding with Steel Q235 Q345

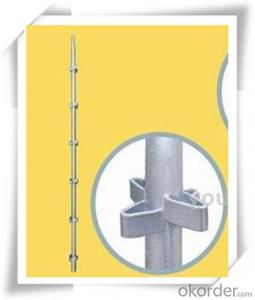

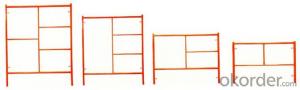

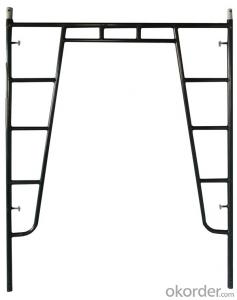

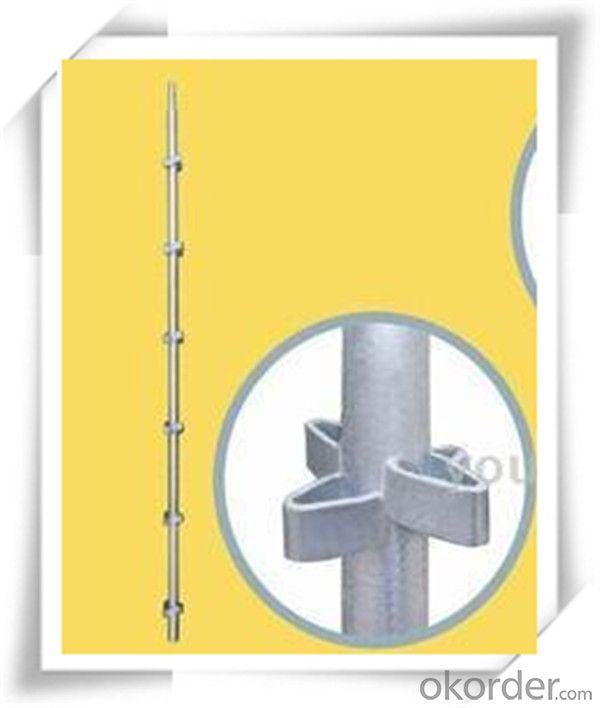

Name | Cup-lock System Scaffolding with Painted Steel Q235 Q345 |

Place of Origin | China |

Brand name | CNBM |

Main Material | Q345 ,Q235 |

Surface Treatment | High Protected Painted, Powder Coating, Electric Gavenized, Hot Dip Gavenized. |

Color | Silver, Orange |

Certificate | SGS, EN74, ISO |

Features | Automatic Welding |

Service | OEM Service available |

MOQ | 20ton |

Payment | T/T or L/C in sight |

Delivery Time | About 20-30 days after confirmation |

Packing | in bulk or steel pallet or as your request |

production capability | 100 tons per day |

| Kwikstage System Scaffold Standard / Verticals | |||

| Model | Description | Weight(kg) | Weight(lbs) |

| KS.S.2970 | Kwikstage Standard 2970mm(9'9") | 17.37 | 38.29 |

| KS.S.2475 | Kwikstage Standard 2475mm(8'2") | 14.59 | 32.17 |

| KS.S.1980 | Kwikstage Standard 1980mm(6'6") | 11.87 | 26.18 |

| KS.S.1485 | Kwikstage Standard 1485mm(4'10") | 9.08 | 20.02 |

| KS.S.990 | Kwikstage Standard 990mm(3'3") | 6.29 | 13.87 |

| KS.S.495 | Kwikstage Standard 495mm(1'8") | 3.50 | 7.71 |

| |||

| Kwikstage System Scaffold Ledger / Horizontal | |||

| Model | Description | Weight(kg) | Weight(lbs) |

| KS.L.3048 | Kwikstage Ledger 3048mm(10') | 11.90 | 26.23 |

| KS.L.2438 | Kwikstage Ledger 2438mm(8') | 9.79 | 21.58 |

| KS.L.1829 | Kwikstage Ledger 1829mm(6') | 7.60 | 16.75 |

| KS.L.1524 | Kwikstage Ledger 1524mm(5') | 6.51 | 14.35 |

| KS.L.1268 | Kwikstage Ledger 1268mm(4'2") | 5.59 | 12.32 |

| KS.L.1219 | Kwikstage Ledger 1219mm(4') | 5.41 | 11.92 |

| KS.L.914 | Kwikstage Ledger 914mm(3') | 4.32 | 9.52 |

| KS.L.762 | Kwikstage Ledger 762mm(2'6") | 3.77 | 8.31 |

| |||

| Kwikstage System Scaffold Transom | |||

| Model | Description | Weight(kg) | Weight(lbs) |

| KS.T.8 | Kwikstgae Transom 2438mm (8') | 19.51 | 43.02 |

| KS.T.6 | Kwikstgae Transom 1829mm (6') | 14.85 | 32.74 |

| KS.T.5 | Kwikstgae Transom 1524mm (5') | 12.46 | 27.47 |

| KS.T.42 | Kwikstgae Transom 1268mm (4'2") | 10.56 | 23.28 |

| KS.T.4 | Kwikstgae Transom 1524mm (4') | 10.20 | 22.49 |

| KS.T.3 | Kwikstgae Transom 914mm (3') | 7.81 | 17.22 |

| KS.T.26 | Kwikstgae Transom 762mm (2'6") | 6.69 | 14.75 |

| KS.T.19 | Kwikstgae Transom 530mm (1'9") | 4.96 | 10.94 |

| |||

| Kwikstage System Scaffold Return Transom | |||

| Model | Description | Weight(kg) | Weight(lbs) |

| KS.RT.2438 | Kwikstage Return Transom 2438mm (8') | 29.66 | 65.40 |

| KS.RT.1829 | Kwikstage Return Transom 1829mm (6') | 22.17 | 48.88 |

| KS.RT.1524 | Kwikstage Return Transom 1524mm (5') | 18.56 | 40.92 |

| KS.RT.1268 | Kwikstage Return Transom 1268mm (4'2") | 15.52 | 34.22 |

| KS.RT.1219 | Kwikstage Return Transom 1219mm (4') | 14.94 | 32.94 |

| KS.RT.914 | Kwikstage Return Transom 914mm (3') | 11.32 | 24.96 |

| KS.RT.762 | Kwikstage Return Transom 762mm (2'6") | 9.52 | 20.99 |

| |||

| Kwikstage System Scaffold Ladder Access Transom | |||

| Model | Description | Weight(kg) | Weight(lbs) |

| KS.ALT.2438 | Kwikstage Ladder Access Transom 2438mm (8') | 16.88 | 37.22 |

| KS.ALT.1829 | Kwikstage Ladder Access Transom 1829mm (6') | 14.69 | 32.39 |

| KS.ALT.1268 | Kwikstage Ladder Access Transom 1268mm (4'2") | 12.68 | 27.96 |

| |||

| Kwikstage System Scaffold Diagonal Brace / Bay Brace | |||

| Model | Description | Weight(kg) | Weight(lbs) |

| KS.DB.30*25 | Kwikstage Diagonal Brace 3926mm (10'x8'2") | 11.71 | 25.82 |

| KS.DB.30*20 | Kwikstage Diagonal Brace 3635mm (10'x6'6") | 10.96 | 24.17 |

| KS.DB.24*25 | Kwikstage Diagonal Brace 3474mm (8'x8'2") | 10.54 | 23.24 |

| KS.DB.24*20 | Kwikstage Diagonal Brace 3141mm (8'x6'6") | 9.68 | 21.34 |

| KS.DB.18*20 | Kwikstage Diagonal Brace 2695mm (6'x6'6") | 8.52 | 18.79 |

| KS.DB.18*15 | Kwikstage Diagonal Brace 2356mm (6'x4'10") | 7.64 | 16.85 |

| KS.DB.18*10 | Kwikstage Diagonal Brace 2079mm (6'x3'3") | 6.93 | 15.28 |

| KS.DB.15*20 | Kwikstage Diagonal Brace 2498mm (5'x6'6") | 8.01 | 17.66 |

| KS.DB.15*15 | Kwikstage Diagonal Brace 2128mm (5'x4'10") | 7.05 | 15.55 |

| KS.DB.15*10 | Kwikstage Diagonal Brace 1817mm (5'x3'3") | 6.25 | 13.78 |

| KS.DB.12*20 | Kwikstage Diagonal Brace 2351mm (4'2"x6'6") | 7.63 | 16.82 |

| KS.DB.12*15 | Kwikstage Diagonal Brace 1953mm (4'2"x4'10") | 6.60 | 14.55 |

| KS.DB.12*10 | Kwikstage Diagonal Brace 1609mm (4'2"x3'3") | 5.71 | 12.59 |

| KS.DB.07*15 | Kwikstage Diagonal Brace 1669mm (2'6"x4'10") | 5.86 | 12.92 |

| KS.DB.07*10 | Kwikstage Diagonal Brace 1249mm (2'6"x3'3") | 4.77 | 10.52 |

| |||

| Kwikstage System Scaffold Mesh Panel / Brick Guard | |||

| Model | Description | Weight(kg) | Weight(lbs) |

| KS.MP.2438 | Kwikstage Mesh Panel 2438mm(8') | 21.37 | 47.11 |

| KS.MP.1829 | Kwikstage Mesh Panel 1829mm(6') | 15.38 | 33.91 |

| KS.MP.1268 | Kwikstage Mesh Panel 1268mm(4'2") | 11.93 | 26.31 |

| KS.MP.762 | Kwikstage Mesh Panel 762mm(2'6") | 8.82 | 19.45 |

| |||

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Is there a such thing as a scaffold fracture?

- Are you sure you didn't mean to say Scaphoid Fracture. The scaphoid process is a projection coming from your Scapula(shoulder Blade), that connects with the clavicle( )and humerus(arm). Hope this helps thanks.

- Q: I got my industrial pierced about three days ago. The shop I wanted to go to closed so I went to another one that cost a bit more. The guy who pierced it said to only clean it with warm water, but when I got my helix, tounge webbing and angel bites I was told that all new piercings need disinfectant. What are some disinfectants I could use and am I right by doing this or should I listen to the piercer?

- Well you definitely need to use more than just warm water to clean it. Try using something like Provon soap and do sea salt soaks at least twice a day to keep it clean.

- Q: A 56.0kg painter is on a uniform 23.5kg scaffold supported from above by ropes . There is a 5.0kg pail of paint to one side, as shown. How close to the end can he approach safely?

- Torques left, about right rope. Scaffold is 6m long. 23.5/6 = 3.91667kg per metre. 3.91667 x 5m = 19.58335kg/m. 5kg x 3m = 15kg/m. Total = 34.58335kg/m torque. Torque right. 1 x 3.19667 = 3.91667kg/m. Subtract right from left, = 34.58335 - 3.91667 = 30.6667kg/m can be applied by the painter. 30.6667/ 56 = .548 metre, the painter can move to the right of the right rope.

- Q: The role of scaffolding and the basic requirements for scaffolding

- The main function of the scaffold is in height for stacking operations, short distance transport and operation personnel on construction work. The five basic types of high job security risks can occur in the scaffolding on the job.

- Q: What are the main types of bowl buckle scaffold

- Scaffolding is used to build houses, built in the periphery to the workers up and down

- Q: What is the difference between the bowl buckle scaffold and the fastener type steel pipe scaffold? What is the difference?

- Single row are generally used for landing. Its main function is to protect. Specific reference to JGJ 1302011 "construction fastener type steel pipe scaffolding safety technical specifications" in the relevant instructions, and illustrations.

- Q: Iam a student from federal polytecnic damaturu in Nigeria from department of civil engineering.thanks

- 1. ) We really need to paint building and steel to prevent from rust, by then it will help the structure to last long..We all know that rust is one of the problem that loosen the strenght of steel.. 2.) Construction aggregate, or simply aggregate, is a broad category of coarse particulate material used in construction, including sand, gravel, crushed stone, slag, and recycled concrete. Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as reinforcement to add strength to the overall composite material.

- Q: What are the requirements for the erection of the bowl - shaped steel tube scaffold

- Span and step distance is in accordance with the relevant regulations; the top of the free end is more than the specifications is not greater than 50cm, and free from backwater not greater than 30cm;

- Q: I've been wanting an industrial piercing for quite a while now, and thankfully I convinced my parents to let me get it done about two weeks ago. We were on vacation in Florida last week and my mom said I could get it done there if I wanted, so we went into a tattoo shop and asked about it. They told me something I'd never heard before, that they would pierce the holes with hoops and in about a month I could put the barbell in. The piercers told me it would heal a lot easier this way and if the barbell was put in right away I'd end up taking it out because of the pain. This makes sense of course, but I have NEVER heard of it being pierced this way, and once the holes heal, won't they be off in aligning the bar with the piercings, causing me even more pain?They told me if I get it pierced in my home town to tell the piercer to do it the way they suggested but I'm not sure at all. I could take the pain if that was the only issue, but if it would heal better.. I'm not sure. Help? Thanks!

- Stretching shouldn't hurt if you're giving it enough time... so this really isn't a good comparison! A single cartilage piercing doesn't hurt much more than your standard earlobe (lobe being 2, cartilage piercing being 3 on a scale of 1 to 10). But I've never had a scaffold or orbital of any kind, so I don't have much first hand experience. Honestly though I wouldn't worry about it. It will be over in 30 seconds, 1 minute tops. And you get to come away with a pretty new piercing! Yay!

- Q: Scaffolding step span, span, the vertical rod spacing is how much

- The span is the distance between two adjacent poles. The width of the scaffold is the width of the scaffold, which is the distance between two poles.

Send your message to us

Kwikstage System Scaffolding with Steel Q235 Q345 CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords