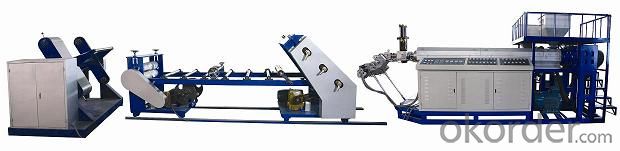

JSM- Automatic Double-Layer Plastic Sheet Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure Features

JSM Double-Layer Plastic Sheet Extruder is developed by taking the advanced technology from both home and abroad into consideration on the basis of the single-layer plastic sheet extruder. It’s applicable in producing multilayer PP, PE and PS sheet, which is used to produce drinking cups, ice-cream cups, and yogurt cups, packing boxed and such plastic vessels. It is one of the main products of our company. It has passed the CE Certification.

Specification:

Main Machine Screw Diameter | Φ105 |

Minor Machine Screw Diameter | Φ80 |

Calendar Roller Diameter | 293mm |

Sheet Thickness | 0.3-2mm |

Main Machine Power | 45kw |

Minor Machine Power | 30kw |

Output | 185kg/h |

Dimension (L×W×H) | 10.5×4.2×2.7m |

Weight | 8000kg |

Power Supply | 380/3/4/59(Volt/Ph/Line/Hz) |

FAQ:

Where is your factory located:

Our production base is located in Zhejing Province.

Will your side be responsible for installation, is it for free?

We will be in charge of installation, but you have to pay related fee.

What is the advantage of your company?

Our company is the largest building materials and equipment suppplier in China, second in the world, as a state-owned company, we strictly focus on quality management, our production is under the standard of IS0 9001. for the more, we have experienced logistic team, which is responsible for puntual deilivery and cheapes shipping charge.

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Do you want water spray, dry filter, carbon adsorption, fan, and discharge? Will that be better, thank you?Chasing the answerIf the exhaust gas contains acid and alkali waste gas (slightly acid base acceptable), there is no need to water spray, the main role of water spray is used to neutralize the acid and alkali containing exhaust gas. The exhaust gas is dry organic waste gas, only dry filter, activated carbon adsorption odor can be discharged.

- Q: Basic parameters of extruder screw

- 2. The ratio of the length to diameter of the screw, the length of the screw L/Ds and the ratio of L to the diameter of the screw Ds is called the ratio of length to diameter. When the other conditions are constant (such as the diameter of the screw), increasing the ratio of length to diameter means increasing the length of the screw. The L/Ds value is large and the temperature distribution is reasonable, which is beneficial to the mixing and plasticizing of plastics. At the same time, the heating time of the plastic in the barrel is longer, and the plasticization of the plastic will be sufficient and more uniform. So as to improve the quality of machine plastics. If the plastic quality requirement is constant, the rotation speed of the screw can be increased after the ratio of length to diameter increases, thereby increasing the extrusion amount of the plastic. However, too large length diameter ratio, power consumption will increase the screw, and the screw and barrel of the processing and assembly of chicken more difficult; the possibility of screw bending will increase, will cause the abrasion of the screw and the inner wall of the cylinder, reduce the service life. In addition, the heat sensitive plastic, large diameter and long retention time than thermal decomposition, the plasticizing and impact plastic extrusion quality. Therefore, in the full use of the advantages of increasing the ratio of length to diameter, the selection should be based on the physical properties of the processed plastics and the quality requirements of the products.

- Q: What impact does the extruder vacuum pump open or close on the extrusion product?

- If the vacuum pump is opened, the air in the extruded product will be removed and the product material will be more closely packed.

- Q: Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Cable extruder type 657090 machine, describes the diameter of the screw, the unit is mm.The greater the number, the greater the equipment, the greater the amount of gumIt is usually marked on the control cabinet of the equipment

- Q: Produce 10 square wires with the smallest extruder

- If the production of single core line, then 50 machines can also do, but low efficiency, unstable line,.70 or 90 machine ideal

- Q: the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Is the fitting of the moving parts normal?.Is there an impact on the extrusion chamber?.

- Q: Comparison of injection molding machines and Extruders

- Considerations for extruder use:1, extrusion machine is running forward, avoid reverse2, avoid fasting operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon3, the extruder inlet, vent hole is strictly prohibited access to iron and other miscellaneous, so as not to cause accidents, affect production4, safe use of electricity, grounding wire5. When the machine is running, it is forbidden to touch the rotating parts such as the material inlet, the material outlet, the belt, the gear and so on6, before using the machine should be injected with lubricating oil, so as not to cause damage to the machineSince the extruder as one of the three synthetic plastic material since the advent of rapid development.

- Q: PLC based extrusion machine control system design graduation thesis and PLC based injection molding machine control system thesis content?

- Tip three: select the topic according to the documents. Literature is the foundation of support, enrich the direction and point of view, but also can reflect the research result, the author embarks from the existing literature, topic and refine the title, became the third skills.

- Q: What are the components of an extruder?

- The driving system of an extruder is to drive the screw, providing the torque and speed required by the screw in the extrusion process, usually consisting of an electric motor, a reducer, and a bearing.3. heating and cooling device for extruderHeating and cooling are necessary conditions for the process of making a plastic extruder. It includes two aspects:(1) now host extruder is usually divided into electric heating, resistance heating and induction heating, heating installed in the fuselage, neck, head of each part. The heating device heats the plastic in the outer barrel to increase the temperature required for the process operation.(2) the cooling device is designed to ensure that the plastic is in the temperature range required by the process. Specifically, to eliminate the excess heat generated by the shear friction of the screw rotation, in order to avoid the temperature is too high, so that plastic decomposition, coke burning or stereotypes difficult. Cylinder cooling water cooling and air cooling is divided into two kinds, small and medium sized extrusion machine adopts air cooling is more appropriate, large use more water or two kinds of combined cooling; cooling water cooling screw mainly adopts the center, the purpose is to increase the solids conveying rate, stable glue volume, and improve product quality; but in the cooling hopper one is, in order to strengthen transport of solid material, prevent warming plastic sticky jam outlet, two is to ensure the normal work of the transmission part.

- Q: How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

Send your message to us

JSM- Automatic Double-Layer Plastic Sheet Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords