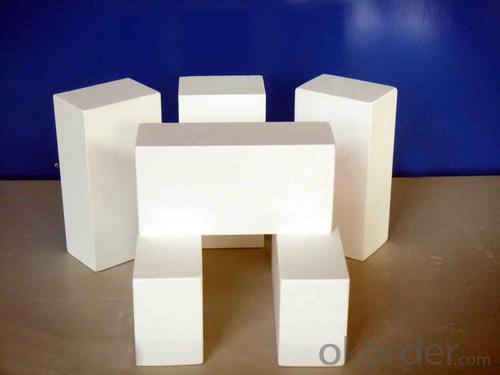

Insulating Fire Brick - JM Mullite Thermal Storage Bricks Thermal Insulating Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bubble Alumina Brick. We stock in both 2.5 & 3” sizes. We also carry double bump interlocking anchor styles. For use up to 1800C, these brick have excellent insulating properties as well as high hot strengths.

Insulating firebrick, we carry produces thirteen types of Insulating Fire Brick for use in applications from 2,000°F (1,093°C) to 3,200°F (1,760°C). Each type is formulated to meet specific thermal and physical requirements and after firing is machined to precise tolerances.

Made from high purity refractory clays and other ceramic raw materials, these insulating fire brick contain a carefully graded organic filler which is burned out during manufacture to give a uniform controlled pore structure.

Advantages of bubble alumina brick.

High Insulating Va

The high compressive strength of bubble alumina brick allows for self-supporting structures at elevated temperatures. Insulating fire brick are compatible with dense fire brick and add strength to the whole construction.

.

Strong

The high compressive strength of bubble alumina brick allows for self-supporting structures at elevated temperatures. Insulating fire brick are compatible with dense fire brick and add strength to the whole construction.

Low Heat Storage

Lower heat storage versus dense brick means reduced fuel costs in cyclically operated heating equipment.

Application

DJM 26 Light Weight Insulating fire brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used for insulation in sewage treatment plants?

- Yes, insulating fire bricks can be used for insulation in sewage treatment plants. These bricks are designed to withstand high temperatures and provide excellent thermal insulation. They can be used to line the walls, floors, and ceilings of sewage treatment plants to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks have good resistance to chemicals and moisture, making them ideal for use in environments with high levels of humidity and corrosive substances found in sewage treatment plants.

- Q: What are the dimensions of insulating fire bricks?

- The dimensions of insulating fire bricks can vary, but they are typically rectangular in shape and commonly come in sizes such as 9" x 4.5" x 2.5" or 9" x 4.5" x 3".

- Q: Can insulating fire bricks be used in the construction of gas kilns?

- Yes, insulating fire bricks can be used in the construction of gas kilns. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for gas kilns where heat retention is crucial.

- Q: How do insulating fire bricks perform in terms of thermal stability?

- Insulating fire bricks are known for their excellent thermal stability. They are designed to withstand high temperatures and provide insulation in various industrial applications. These bricks are made from lightweight refractory materials that have low thermal conductivity, allowing them to effectively trap and retain heat. One of the main reasons insulating fire bricks are preferred for thermal insulation is their ability to maintain their structural integrity even under extreme temperature conditions. They have a high resistance to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. This makes them ideal for use in furnaces, kilns, and other high-temperature environments. Furthermore, insulating fire bricks have a low coefficient of thermal expansion, which means they do not expand or contract significantly when exposed to heat. This property ensures that the bricks maintain their shape and do not develop cracks or gaps due to thermal stress. In terms of thermal stability, insulating fire bricks also have good insulation properties. They have a high insulating value, which means they can effectively reduce heat loss and conserve energy. This is beneficial in applications where maintaining a consistent temperature is crucial, as it helps to minimize heat transfer and improve overall energy efficiency. Overall, insulating fire bricks perform excellently in terms of thermal stability. Their ability to withstand high temperatures, resist thermal shock, and provide effective insulation make them a reliable choice for various industrial and commercial applications.

- Q: Can insulating fire bricks be used in electric arc furnaces?

- Insulating fire bricks are capable of being used in electric arc furnaces. Constructed from lightweight materials possessing excellent insulation capabilities, these bricks are well-suited for scenarios necessitating heat insulation. Due to the high temperatures generated by electric arc furnaces, effective insulation is imperative to confine the heat within the furnace chamber. The insulating fire bricks are able to endure the extreme heat emitted by these furnaces, thus averting heat loss and conserving energy. Furthermore, their insulating properties contribute to maintaining a steady temperature inside the furnace, ensuring the efficient melting and refining of metals or other materials. Consequently, insulating fire bricks present a suitable option for implementation in electric arc furnaces.

- Q: How do insulating fire bricks compare to other insulation materials like ceramic fiber?

- Insulating fire bricks are generally denser and more durable compared to ceramic fiber insulation materials. While ceramic fiber offers excellent thermal insulation and is lightweight, insulating fire bricks provide better resistance to high temperatures and mechanical stress. Additionally, insulating fire bricks have lower thermal conductivity and higher compressive strength, making them suitable for applications that require long-term thermal insulation and structural support.

- Q: Can insulating fire bricks be used for insulation in heat recovery systems?

- Indeed, insulating fire bricks have the capability to serve as insulation within heat recovery systems. These bricks are specially crafted to endure elevated temperatures and deliver efficient thermal insulation. By possessing low thermal conductivity, they possess the ability to reduce heat dissipation and enhance heat recovery within a system. Consequently, they are frequently implemented in diverse industrial settings, including kilns, furnaces, and ovens, where temperature regulation and energy efficiency are paramount. Therefore, these bricks present a viable option for insulating heat recovery systems, facilitating the optimization of waste heat recovery and utilization.

- Q: Can insulating fire bricks be used in rocket stove designs?

- Insulating fire bricks are capable of being incorporated into the designs of rocket stoves. Rocket stoves are renowned for their efficient combustion and heat transmission, and the utilization of insulating fire bricks can enhance this level of performance. These bricks are produced from lightweight materials that possess excellent insulating properties, allowing them to effectively retain and reflect heat. The combustion chamber of a rocket stove is typically lined with insulating fire bricks in order to maximize the transfer of heat to the cooking surface or the area being heated. The bricks aid in the retention of heat within the combustion chamber, ensuring that a greater portion of the energy generated from the burning fuel is utilized to heat the cooking surface, rather than being dissipated into the surrounding environment. Moreover, insulating fire bricks are capable of enduring high temperatures, making them an ideal choice for inclusion in rocket stove designs. They are specifically engineered to withstand the intense heat generated by the combustion process, guaranteeing that the bricks will not fracture or shatter under such circumstances. In conclusion, the incorporation of insulating fire bricks into the designs of rocket stoves can enhance the efficiency and heat transmission of the stove, resulting in a more efficient and sustainable solution for cooking or heating purposes.

- Q: Can insulating fire bricks be used in rotary kilns?

- Yes, insulating fire bricks can be used in rotary kilns. Insulating fire bricks are designed to have low thermal conductivity, which helps to reduce heat loss and improve energy efficiency in high-temperature applications like rotary kilns. Additionally, these bricks are lightweight and have good thermal shock resistance, making them suitable for the harsh and dynamic conditions within a rotary kiln.

- Q: Is it possible to paint or coat insulating fire bricks?

- Yes, it is possible to paint or coat insulating fire bricks. However, it is important to use heat-resistant paints or coatings that can withstand high temperatures. Regular paints or coatings may not be suitable as they can crack or peel due to the intense heat. It is recommended to consult with a professional or refer to the manufacturer's guidelines to ensure the correct type of paint or coating is used for insulating fire bricks.

Send your message to us

Insulating Fire Brick - JM Mullite Thermal Storage Bricks Thermal Insulating Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords