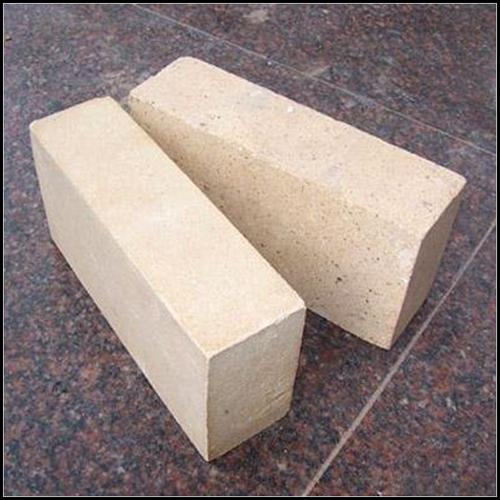

Insulating Fire Brick for Furnace Lining/High Alumina Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 800 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Brick

CMAX firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay by mixing, press-forming, drying, sintering and machining. Bricks contain carefully-graded organic fillers which are burned out during sintering to give a uniform controllable pore structure. This technique makes product feature low thermal conductivity and excellent heat insulation

Features

1.Dense crystal structure.

2.High bulk density.

3.High mechanical strength at normal and high temperature.

4.Good thermal shock resistance.

4.Low creep and low permanent liner change rate.

5.High performance of chemical stability and alkaline medium erosion resistance.

Application

1.Building material industry,kiln,heating equipment and the inwall of high—temperature pipe line

2.Chemical industrial high temperature of reaction equipment inwall

3.Power plant ,gas turbine engine and heat insulation of unclear power

4.The fire proof of high—rise building

5.Furnace door of kiln

6.High-temperature filter material

Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Can insulating fire bricks be used in copper smelting furnaces?

- Yes, insulating fire bricks can be used in copper smelting furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in furnaces. They are made from materials that can handle the extreme heat generated during the smelting process and can effectively retain and reflect heat back into the furnace. This helps to maintain the desired temperature and improve energy efficiency. Additionally, insulating fire bricks can help to reduce heat loss, resulting in faster and more efficient copper smelting. Therefore, using insulating fire bricks in copper smelting furnaces is a common practice in the industry.

- Q: Can insulating fire bricks be cut to custom sizes?

- Indeed, custom sizes can be achieved when cutting insulating fire bricks. These bricks are commonly crafted from lightweight materials like ceramic fibers or lightweight aggregates, facilitating their relative ease of cutting. A range of tools, including saws, knives, and specialized cutting equipment, can be utilized to achieve this. However, it is crucial to prioritize proper safety measures and employ suitable tools and techniques to attain a precise and flawless cut. Furthermore, consulting the manufacturer's instructions or seeking expert guidance is recommended to ensure that the cutting procedure does not compromise the structural integrity or thermal characteristics of the insulating fire bricks.

- Q: Is it necessary to abolish the technical regulations for the construction of self thermal insulation masonry building with sludge sintering insulation bricks?

- The original "technical specification for self insulation masonry building with silt insulation bricks" has been replaced by DGJ32/TJ78-2009 (technical specification for automatic insulation wall system of sintered silt non bearing insulating brick) DGJ32/TJ78-2013.

- Q: Can insulating fire bricks be custom-made?

- Indeed, it is possible to manufacture insulating fire bricks according to specific specifications. Typically, insulating fire bricks are crafted using lightweight materials like vermiculite, perlite, or refractory fibers, which are easily shaped into various forms and sizes. With this versatility, manufacturers can produce tailor-made insulating fire bricks to cater to specific demands and purposes. The customization options available may involve alterations in dimensions, thermal conductivity, compressive strength, and density. By adjusting the composition and design of the insulating fire bricks, they can be optimized to function optimally within specific temperature ranges, insulation requirements, and environmental conditions. Consequently, customers have the opportunity to collaborate with manufacturers in order to develop personalized solutions that perfectly align with their individual requirements.

- Q: Are insulating fire bricks resistant to alkali attack?

- Yes, insulating fire bricks are generally resistant to alkali attack.

- Q: Can insulating fire bricks be used in brick kilns?

- Yes, insulating fire bricks can be used in brick kilns. Insulating fire bricks are designed to have high thermal resistance, which makes them an ideal choice for insulating the walls of a brick kiln. These bricks can withstand extremely high temperatures and help to maintain consistent heat levels within the kiln. By using insulating fire bricks, the heat loss from the kiln is minimized, resulting in improved energy efficiency and reduced fuel consumption. Additionally, the use of insulating fire bricks can also help to protect the outer layers of the kiln from excessive heat, preventing damage and prolonging the lifespan of the kiln. Overall, insulating fire bricks are a suitable and effective choice for use in brick kilns.

- Q: What are the insulation materials for heating buried pipelines?

- The heat preservation layer is composed of antirust paint, heat insulating material, moisture-proof layer (used for pipeline in the trench), protective layer, anticorrosive layer (used for trench or directly buried pipe) and top coat (or fireproof coating).The waterproof layer can be used asphalt or aluminum foil protective layer with glass cloth or galvanized steel.

- Q: Can insulating fire bricks be used in wastewater treatment plants?

- Yes, insulating fire bricks can be used in wastewater treatment plants. They are often used in the construction of furnaces, kilns, and other high-temperature applications in these plants to provide thermal insulation and retain heat efficiently.

- Q: What is the typical thermal diffusivity of an insulating fire brick?

- The thermal diffusivity of an insulating fire brick can vary depending on its composition and manufacturing process. However, typically, insulating fire bricks have thermal diffusivity values ranging from approximately 0.05 to 0.2 mm²/s. Thermal diffusivity measures the speed at which heat can pass through a material. A low thermal diffusivity suggests that the material is a good insulator, as it does not conduct heat quickly. Insulating fire bricks are designed to have low thermal diffusivity to minimize heat transfer and provide effective insulation in high-temperature applications, like furnaces, kilns, and fireplaces. It is important to note that the specific thermal diffusivity of an insulating fire brick can be influenced by various factors, including the type of raw materials used, the manufacturing process (such as firing temperature and duration), and any additives or coatings applied to enhance insulation properties. Therefore, consulting the manufacturer's specifications or conducting specific tests is crucial to determine the thermal diffusivity of a particular insulating fire brick.

- Q: What is the typical creep resistance of an insulating fire brick?

- The typical creep resistance of an insulating fire brick can vary depending on the specific composition and manufacturing process of the brick. However, in general, insulating fire bricks have good creep resistance properties due to their high temperature stability and low thermal conductivity. These bricks are designed to withstand high temperatures and are often used in applications where thermal insulation and resistance to thermal stress are important, such as in kilns, furnaces, and other high-temperature industrial processes. Insulating fire bricks are typically made from lightweight refractory materials, such as alumina, silica, or other refractory oxides. These materials are chosen for their ability to resist deformation and maintain their shape under high temperatures. Creep is the gradual deformation or flow of a material under the influence of constant stress over time. In the case of insulating fire bricks, the creep resistance refers to their ability to maintain their structural integrity and dimensional stability even when exposed to prolonged high temperatures. Insulating fire bricks are designed to have low creep rates, meaning that they exhibit minimal deformation or flow under sustained stress. This is achieved through careful selection of raw materials, controlled manufacturing processes, and the addition of certain additives or binders that enhance the creep resistance of the brick. While the specific creep resistance values may vary, insulating fire bricks are generally engineered to withstand high temperatures and exhibit good resistance to creep, ensuring long-lasting performance and durability in high-temperature environments.

Send your message to us

Insulating Fire Brick for Furnace Lining/High Alumina Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 800 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords