Angle iron solid state high frequency welding equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: Other

Place of Origin: Hebei, China (Mainland)

Brand Name:CNBM Group

Model Number: GGP600-0.2-H

Voltage: 1300A

Current: 450V

Weight: 2t-3t

Usage: angle iron welding

Certification: ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Frequency: 150~ 200 kHz

Efficiency: more than 85%

Pipe: 200x200mm~300x300mm

Thickness: 6.0~12.0mm

Welding: induction welding or contact welding

Speed: Induction welding ≥15m/min Contact welding ≥18m/min

color: make as customer requirement

cooling way: water water or air water

Maintenance: easy & low cost

Board: self made

Packaging & Delivery

| Packaging Details: | 1.Standard export wooden package. 2.Fumigated seaworthy wooden boxes 3.Upper/lower back angles for lifting 4.Mark as customer's requirement 5.Follow customer's packing standard 6.20GP or 40GP container (for reference) |

|---|---|

| Delivery Detail: | 20 days |

Specifications

ISO9001

High efficiency & power saving

China famous brand

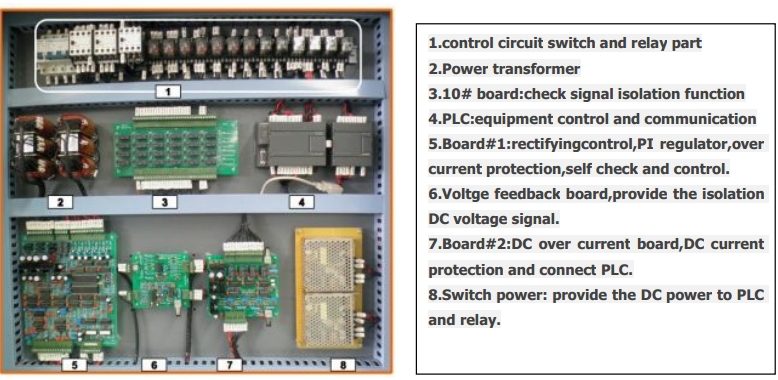

Full digital control system

HMI and fault diagnosis system

angle iron solid state high frequency welding equipment

1.Range of application

Steel pipe welding, Iron pipe welding, stainless pipe welding, aluminium tube welding, copper tube welding, H-beam welding and special pipe welding.

2.Functional structure

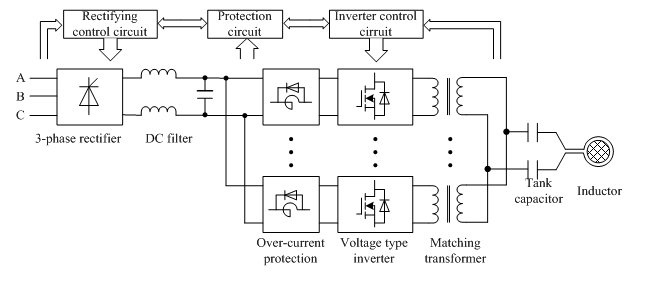

The solid state high frequency equipment mainly used for HF welded steel pipe line, it is a typical AC-DC-AC variable frequency structure. Rectifier adopts 3-phase bridge style thyristor phase-control rectifier circuit, DC side adopts inductor, capacitor to compose LC filter which meet the working requirements of voltage type inverter. The voltage type inverter adopts modularization parallel structure to extend power supply power, each inverter module is single phase MOSFET bridge style circuit connected with series resonance tank circuit by H.F. matching transformer. On one hand, the matching transformer realizes power combination and impedance matching; on the other hand it realizes electric isolation of load and power supply. To put effective and swift protection on over-current malfunction of voltage type inverter, our company introduces special and stable over-current protection circuit which guarantees safe and stable running of inverter.

The whole set of solid state H.F. welder comprises of switchgear rectifying cabinet, inverter output cabinet, connecting optical fiber, circulation soft water cooling system, central operator console, mechanical adjustment device, contact welding pole plate and contact pin (contact welding) and etc

3.Circuit structure of Square tube HF induction heating welding machine

4.Equipment composing

The whole set of solid state H.F. welder comprises of switchgear rectifying cabinet, inverter output cabinet, connecting optical fiber, circulation soft water cooling system, central operator console, mechanical adjustment device, contact welding pole plate and contact pin (contact welding) and etc.

5.Brief introduction for Square tube HF induction heating welding machine

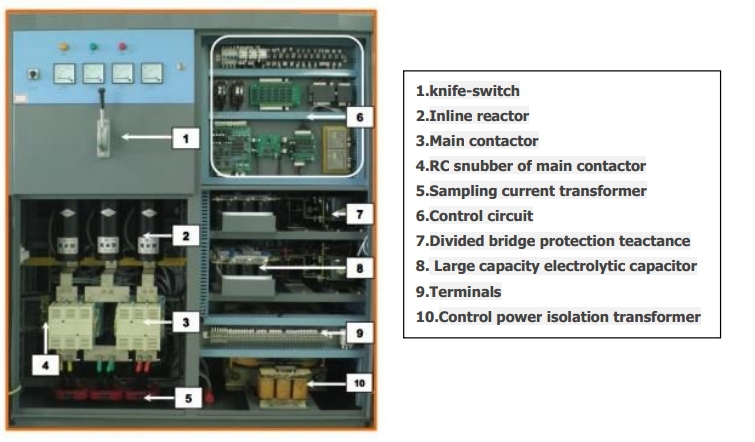

Switchgear rectifying cabinet

Designed with integration of switchgear cabinet and rectifying part, besides achieving switchgear cabinet functions, it also has rectifying control functions of solid state H.F. welders.

Installed line-in switch, line-in current meter, voltage meter (can be switched) and line-in voltage indication lamp.

Installed 3-phase full-controlled thyristor Rectification Bridge to realize power adjustment of the HF welder.

Installed flat-wave reactor, flat-wave capacitor and filter to improve the flat-wave coefficient.

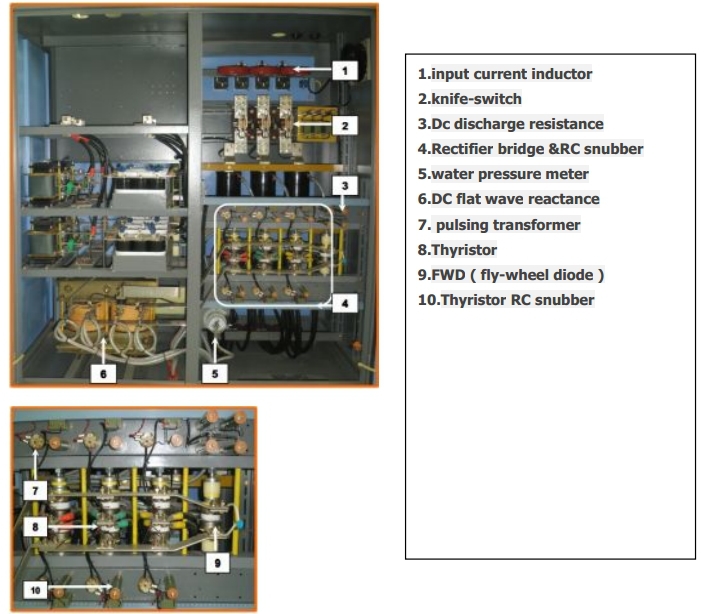

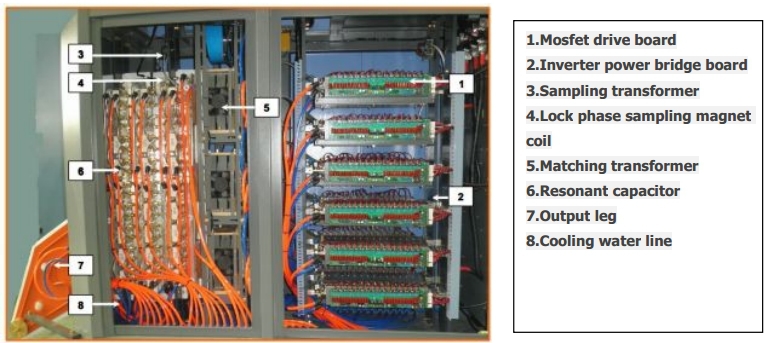

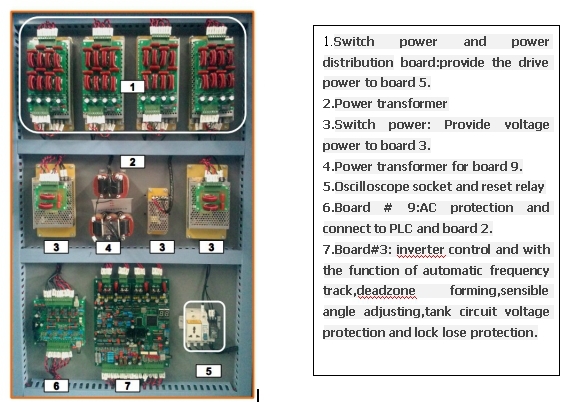

Inverter output cabinet

The inverter part is consisted of MOSFET single-phase inverter bridge connected in parallel. The power of single-phase bridge is 120kW; the inverter bridge adopts the building block method to realize power superposition. Every piece of bridge plates is designed in the shape of a drawer, which is very easy to install and repair.

The matching transformer is adopted for power combination, also it adopts the output method by of secondary resonance and non-welding transformer, tank circuit resonance capacitor (low voltage) resonates with the sensor directly, and the output pole plate offers required power transmission for pipe welding.

Adopted sealed equipment case, installed with air conditioner.

Circulation soft water cooling system

circulation soft water is used as cooling water with temperature and water level indicator and protection.

Central operation console

It realizes solid state H.F. welder remote operation and power regulation, installed with LCD which indicates armature voltage, field voltage indication and of DC drive and DC voltage, DC current indication of H.F. welders.

Mechanical adjustment device

Applied to install inverter output cabinet and adjust inductor position. 2D and 3D adjustable

- Q: What should be paid attention to when welding the air conditioner copper pipe welding machine?

- Don't let out the water,

- Q: What is the welding machine for glass fibre reinforced plastic cable protection tube?

- The glass fiber reinforced plastic material joint is only suitable for bonding and riveting. It can not be welded, so there is no special welding machine.

- Q: How to weld the air conditioner copper tube welding?

- How to weld air conditioner copper tube welding well?:We should use the "copper", is to use the gas welding gun burnt copper solder, the copper pipe welding. It should be equipped with the welding torch, tools and solder.

- Q: Which brand is the best for plastic pipe welding machine? How to ensure the quality of PE pipe welding machine?

- Plastic welding is of course with the Swiss LEISTER brand well, can use the mirror to PE pipe welding butt welding

Send your message to us

Angle iron solid state high frequency welding equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords