Industry Used Ductile Iron Manhole Cover EN124

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) Designs: based on EN124 standard and according to customer's drawing or

samples.

2) Applications: water supply and drainage, fire engineering, natural

3) Inspection: in-house or the third party as per customer's request.

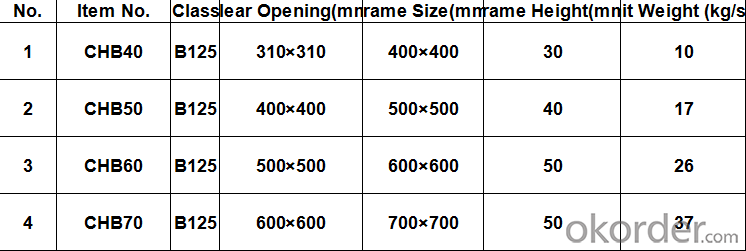

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Packaging and Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

Pictures

FAQ:

Why imported Composite Manhole cover/Grating fromChina?

1. Very competitive price, it will save you third or even half cost;

2.Good quality, don't worry much about the quality, actually, most of the building materials you buy from Miami, Dubai ,Italy, South Africa or your local market are imported from China. So why not buy direct from China. The key point is to find a reliable supplier who is honest and professional to take care of the quality and delivery time.

3.Chinahas full range of Manhole covers which Follow En124 for your market, like A15,B125,C250,D400.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- German winter three step mirror polishing 2013 new processYou can free proofing!

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Because the grinding machine is layer by layer. And the material inside the casting is not completely uniform.

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- According to the requirements of the workpiece annealing, there are many kinds of annealing process specifications, such as full annealing, spheroidizing annealing and stress relieving annealing. Steel the steel quenching is heated to the critical temperature Ac3 (hyposteel) or Ac1 (hypereutectoid steel) above a certain temperature, holding time, so that all or part of 1 Austenitic, then the cooling rate is greater than the critical cooling rate of fast cooling to below Ms (or near Ms isothermal) of martensite the body (or bainite transformation) heat treatment process. Aluminum alloys, copper alloys, titanium alloys, tempered glass and other materials are usually treated by solid solution or heat treatment with rapid cooling process. Tempering is a heat treatment process where the workpiece is hardened and heated to a temperature below AC1, which remains cool for a certain period of time and then cools to room temperature. Tempering generally followed by quenching, the purpose is: (a) to eliminate the residual stress caused by quenching, prevent deformation and cracking; (b) hardness, strength, plasticity and toughness of workpiece is adjusted, to use performance requirements; (c) the size of organization and stability, ensure the accuracy improvement; (D) and to improve the processing performance. Tempering is therefore the last important step in obtaining the desired properties of the workpiece. According to the tempering temperature range, tempering can be divided into low temperature tempering, medium temperature tempering and high temperature tempering. This answer is recommended by the questioner

- Q: What method of casting does not rust? I think the sample is like oil

- Close to the solder, and slowly dissolve is hot melt double-sided adhesive, otherwise it is oily double-sided adhesive.

- Q: In theory, which is more expensive, forging parts or casting parts?

- The structure of the casting is relatively flexible in design, and the modeling is easy to realize.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Single for this problem, the direct casting out of course good. But many times because of the limitations of the process, so we choose the post-processing hole

- Q: How to cast iron and wrought iron collocation

- 3, if you have a file in the hand, can be used to file to see finish can also make a judgment from the file down the iron can also be seen, but this is beyond your request, it can be done in the factory. 4, if placed in the grinder grinding, see iron spark from a judge or iron wrought iron, but this is only to do in the factory. About it, may not be full, but through these methods, generally can distinguish between iron or wrought iron.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 2, heat aging (artificial aging), also known as stress annealing, is to heat the casting to 550-650 degrees, insulation 2 - 4h, with the furnace cooling to 150 - 200T, and then baked.

- Q: Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

Send your message to us

Industry Used Ductile Iron Manhole Cover EN124

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches