Industrial Aluminum Foil Sheets - Price for 5052 Aluminium Sheet/Aluminium Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Price for 5052 Aluminium Sheet/ Aluminium Plate

l Specification

Commodity | Price for 5052 Aluminium Sheet/ Aluminium Plate |

Material | 1050,1060,1100,2A16(LY16),2A06(LY6),3003,3004,5052,5005,5083, 6061,7075,8011 |

Finish (Surface) | Hairline Finish,Mirror Finish,Oxidation Finish,PS Finish,Embossed Finish |

Thickness | 0.15mm~200mm |

Width | 10mm~2500mm |

Length | 2000mm~2500mm |

Application | Aluminium Sheet can apply to Lighting,solar reflective film,building appearance, interior decorating: Ceilings,walls, furniture,cabinets,elevators, signs, nameplates,bags,automotive interior and exterior decoration Upholstery:Photo Frame;household appliances:refrigerators,microwave ovens,audio equipment,etc. aerospace and military aspects, such as China's large aircraft manufacturing,the Shenzhou spacecraft series,satellite.the mechanical parts processing,mold making,chemical/thermal insulation pipes coated. |

Package | Standard seaworthy package (wooden boxes package,pvc package, and other package) |

Delivery Time | According to the quantity you ordered |

Payment Term | T/T,L/C,Western Union |

Advantage | Good quality with reasonable price |

l Packaging & Delivery

Packaging detail: wooden pallets that are suitable for long distance exporting

Delivery detail: 25-30 days after receiving L/C or payment in advance

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. Aluminium sheet is a popular product in CNBM. With best quality and service, we have won reputation around the world.. |

l CNBM World Wide

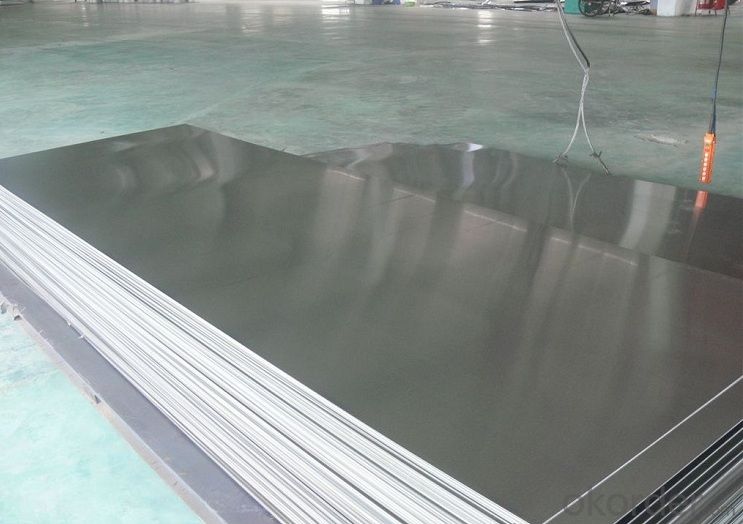

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What are the different types of edges available for aluminum sheets?

- Aluminum sheets offer a variety of edge options to suit different applications and desired appearances. Firstly, there is the straightforward straight edge option. This involves cutting the aluminum sheet in a straight line without any additional alterations or shaping. Another choice is the beveled edge, accomplished by cutting the aluminum sheet at an angle, typically 45 degrees. This creates a chamfered or sloping edge, often used for decorative purposes or to minimize sharpness. For a smooth and rounded edge, the rolled edge is a popular option. By bending the edge of the aluminum sheet, a rounded finish is achieved. This is commonly chosen for safety reasons, as it eliminates sharp edges. A hemmed edge involves folding the aluminum sheet's edge back onto itself, resulting in a double layer of material. This offers increased strength and durability, making it suitable for applications where the edge will be exposed or subject to wear and tear. In industries like aerospace and automotive, the tapered edge is frequently utilized. This involves gradually reducing the thickness of the aluminum sheet towards the edge, reducing weight while maintaining strength. Lastly, there is the flanged edge, created by bending the aluminum sheet's edge at a right angle to form a lip or flange. This type of edge is commonly employed when the aluminum sheet needs to be attached or joined with other materials. Ultimately, the choice of edge type depends on specific project requirements, encompassing functionality, aesthetics, and safety considerations.

- Q: How much is the aluminum plate with a thick 2mm 1000*2000? Thanks

- Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: is there aluminum oxide on the surface of aluminum sheet after being polished by abrasive paper?

- aluminum will be oxided as aluminum oxide once being exposed in air.

- Q: How do you clean and maintain aluminum sheets?

- To clean and maintain aluminum sheets, follow these steps: 1. Start by wiping the surface of the aluminum sheet with a soft cloth or sponge to remove any loose dirt or debris. Avoid using abrasive materials that can scratch the surface. 2. For regular cleaning, mix a mild detergent or dish soap with warm water in a bucket or sink. Dip the cloth or sponge into the soapy water and gently scrub the aluminum sheet, applying light pressure in circular motions. Be sure to clean both sides of the sheet. 3. Rinse the sheet thoroughly with clean water to remove any soap residue. It's important to remove all traces of detergent as it can leave behind a film or residue. 4. For stubborn stains or grime, you can use a non-abrasive cleaner specifically designed for aluminum surfaces. Apply the cleaner to a cloth or sponge and scrub the affected areas. Rinse with clean water afterward. 5. After cleaning, dry the aluminum sheet thoroughly with a clean, soft cloth to prevent water spots or streaks. It's important to dry it completely to avoid any moisture that can lead to corrosion or oxidation. 6. To maintain the aluminum sheet's shine and protect it from future damage, you can apply a thin layer of aluminum polish or wax using a clean cloth. This will create a protective barrier and enhance the sheet's appearance. 7. Regularly inspect the aluminum sheet for any signs of damage, such as scratches or dents. If you notice any issues, take appropriate steps to repair or replace the sheet to prevent further damage. By following these steps, you can effectively clean and maintain aluminum sheets, ensuring their longevity and preserving their appearance.

- Q: I have tried every possible method that I could find on the web for cleaning aluminum, tungsten, filler wire. Nothing has seemed to work. I've tried looking for leaks in the argon line. I'm getting decent welds but there is gunk in the welds for sure. I'm worried about overall strength of the welds. Does anybody out there know of a tried and true method for cleaning aluminum, tungsten, filler etc. that is sure to work? If I can follow that method and still have problems It could possibly be a problem with the machine. Any help would be much appreciated.

- Preweld cleaning requires two operations: oil/grease removal and oxide removal. As below, remove oils and greases first, then remove the oxide. Don’t reverse this order. Take the following steps before welding aluminum: 1. Remove oil, grease, and water vapor using an organic solvent such as acetone or a mild alkaline solution like a strong soap. You may also use citrus-based degreasers, but be sure to rinse and dry the part before welding. 2. Remove surface oxides with a stainless steel wire brush (used only for aluminum) or strong alkaline or acid. Many welding suppliers sell oxide-removal solutions in spray or squeeze bottles for local application. Exercise extreme care when handling these solutions, and again, rinse and dry the part before welding. 3. Assemble the joint. If it won't be welded immediately, cover the joint with brown Kraft paper to prevent dirt and grit in the air from getting into the joint. 4. Keep the aluminum dry and at room temperature. 5. Weld within a few days. Clean the joint again if it isn't welded within that time. Good luck!!!

- Q: What types of aluminum sheets are recommended for outdoor use due to their properties?

- <p>Yes, there are specific types of aluminum sheets designed for exterior applications. These include aluminum sheets with protective coatings such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a PVDF (Polyvinylidene Fluoride) coating, such as Kynar 500, are highly suitable for exterior use due to their excellent durability and resistance to UV rays, chemicals, and scratches. These coatings help maintain the aluminum's appearance and integrity over time, making them ideal for outdoor applications where exposure to the elements is a concern.</p>

- Q: Are aluminum sheets suitable for electrical connectors?

- Yes, aluminum sheets are suitable for electrical connectors due to their excellent electrical conductivity and corrosion resistance.

- Q: I am looking to purchase a pressure cooker and the size that i want comes in aluminum while alot of the others are made from stainless steel. I am wondering if the metal makes a difference in the funtionality and if one doesn't stand up as well as the other.

- This Site Might Help You. RE: Pressure cooker - aluminum vs. stainless steel? I am looking to purchase a pressure cooker and the size that i want comes in aluminum while alot of the others are made from stainless steel. I am wondering if the metal makes a difference in the funtionality and if one doesn't stand up as well as the other.

- Q: Can aluminum sheets be used for roofing applications?

- Yes, aluminum sheets can be used for roofing applications. Aluminum is a durable and lightweight material that offers excellent resistance to corrosion, making it suitable for use in roofing. It is commonly used in residential and commercial roofing projects due to its longevity and ability to withstand various weather conditions.

- Q: Explain how the use of aluminum sheets can impact the visual appeal of a building.

- <p>Aluminum sheets can significantly enhance the aesthetic appearance of a building due to their versatility, durability, and modern look. They offer a sleek and contemporary design, available in various colors, finishes, and textures, allowing architects to create unique and visually striking facades. Their resistance to corrosion and weathering ensures that the building maintains its appearance over time, while their lightweight nature can contribute to innovative architectural designs. Additionally, aluminum sheets can be easily shaped and cut, enabling complex and intricate designs that add to the visual appeal of the structure.</p>

Send your message to us

Industrial Aluminum Foil Sheets - Price for 5052 Aluminium Sheet/Aluminium Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords