Hydroxypropyl Methyl Cellulose from CNBM Manufacture

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Construction Hydroxypropyl Methyl Cellulose (HPMC)

Brief introduction:

Hydroxypropyl Methyl Cellulose (HPMC) helps building materials apply more easily and perform better. They provide water retention and cohesiveness to mixtures. With special modification, it can be used to control thickening, water demand, workability, sag resistance, strength and other important properties of the final product.

It is widely used as thickener, adhesive, water preserving agent, film-foaming agent in building materials, industrial coatings, synthetic resin, ceramic industry, medicine, food, textile, agricultural, cosmetic and other industries.

Physical and chemical index:

Item | Specification |

CAS NO. | 9004-65-3 |

Appearance | white or light yellow powder |

Moisture Content | ≤5.0% |

PH | 4.0-8.0 |

Particle Size | min. 98% pass through 100 mesh |

Viscosity | 100cps-200000cps, 2% solution |

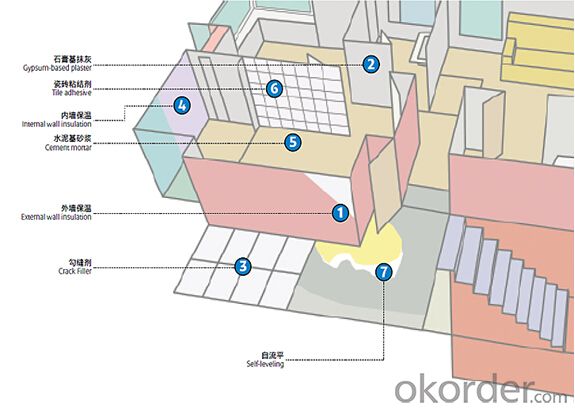

Application in Building:

External wall insulation system (EIFS)

>Bond strength: HPMC can provide the greatest degree of high adhesive bond strength of mortar.

>Performance: The mortar added HPMC has the right consistency, non-sagging. When using, the mortar is easy to work continuously, uninterrupted.

>Water retention: HPMC can wet the wall insulation easily, easy to paste, and also make other additional materials reach the best affects.

>Absorbent: HPMC can minimize the air-entraining volume, lower water absorption of mortar.

>Recommended brand: 75CMAX75000(S), 75CMAX100000(S), 75CMAX200000(S)

Interior and exterior wall interface agent

>Easy to mix, without of agglomeration: HPMC can significantly reduce the friction in the dry powder during the process of mixing with water, which makes it easy to mix and save the blending time.

>Water retention: HPMC can significantly reduce the moisture absorption by the wall. Good water retention can ensure the cement compound with a longer time, also can ensure that workers are able to carry out many times of scraping for the putty on the wall.

>Good working performance stability: even in high temperature environment, HPMC can still maintain good water retention. it is suitable for construction in the summer or hot areas.

>Increased water demand: HPMC can significantly improve the water demand of the putty materials. On the one hand, it improves the operational time after putty put on the wall, on the other hand, it can increase the coating are of the putty, which can make the formula more economical.

>Recommended brand: 75CMAX60000(S), 75CMAX75000(S)

Tile adhesive

>Water retention: HPMC can reduce the moisture absorbed by the substrate and the tile, retain the moisture in the adhesives as much as possible, making mortar still have adhesion after coating for a long time. Significantly extend open time and makes bigger coating area for the worker each time, and improve the efficiency.

>Improve bond strength, improve anti-slip performance: HPMC ensure non sagging of the tiles during working, especially for heavy tile, marble and other stone materials.

>Work performance: The lubricity of HPMC can increase the workability of the mortar significantly, which makes the mortar easy to coating and improve efficiency.

>Improve mortar wetting property: HPMC give mortar consistency, enhance the wetting ability of mortar and substrate, increase the binding strength of wet mortar, especially for the recipe with high water cement ration;

>Recommended brand: 75CMAX40000(S), 75CMAX75000(S), 75CMAX100000(S)

Crack Filler

>Workability: provide the right viscosity, plasticity, and easy to work;

>Water retention: can make the slurry fully hydrated, extending the working time and avoid cracking.

>Anti-hanging: HPMC can make a strong adhesion on the surface for the slurry and not sag;

>Recommended brand: 75CMAX40000(S), 75CMAX75000(S), 75CMAX100000(S)

Self-leveling mortar

>Prevent bleeding: HPMC can play a very good role to prevent the slurry sedimentation, bleeding.

>Maintain liquidity, and improve retention: low viscosity HPMC will not affect the slurry flow effect and easy to work. While possesses certain water retention, makes the good surface effect after self-levelling and avoid cracks.

>Recommended brand: 75CMAX400~600

Gypsum-based plaster

>Water retention: HPMC can retain moisture in the mortar, thus make gypsum completely solid. The higher the viscosity is, the stronger the water-retention capacity, vice versa..

>Sag resistance: allow the worker make the thick coating without causing ripple building.

>Mortar yield: For fixed weight of dry mortar, the exist of HPMC can provide more wet mortar.

>Recommended brand: 75CMAX75000(S), 75CMAX100000(S)

FAQ

Q1.Could we have the sample to test the quality?

Kindly send us your address, we are honored to offer you samples.

Q2. How does your company do regarding quality control?

CNBM a Chinese state-owned enterprise ranked 270th among the global fortune 500 in 2015,

have accreditation in line with standard:ISO 9001:2000,SGS,CIQ certificate.

Q3:What's your Delivery Time?

In generally, the delivery time is 25 days-30 days.We will make the delivery as soon as possible with the guaranted quality.

Q4:What is the convenient way to pay?

L/C , T/T ,Paypal, Western Union and Escrow are accepted,and if you have a better idea , please feel free to share with us .

Q5:Which mode of transport would be better?

In general,we advice to make delivery by sea which is cheap and safe.Also we respect your views of other transportation as well.

- Q: Are biological enzymes harmful to humans?

- Biological enzymes through scientists more than a century of research, usually known as more than 3,000 kinds of enzymes, the current application of biological enzymes in the textile a wide range of technology, fiber modification, silk degumming, raw hemp (ramie, linen, Kenaf) degumming, dyeing and finishing of the desizing, refining, finishing and net cleaning processing, textile printing and dyeing wastewater treatment and garment processing and other aspects of the application. Enzyme technology has a unique advantage in improving dyeing and finishing processes, saving energy, reducing environmental pollution, improving product quality, adding value and developing new raw materials. At present in the textile processing using a wide range of enzyme preparations are mainly cellulase, protease, amylase, pectinase, lipase, peroxidase, laccase, glucose oxidase eight categories.

- Q: The role of catalyst in chemical reactions

- Negative catalysts can be used to control the reaction rate (such as some reaction too fast, instantly release a lot of energy caused by danger, you can join), common is the antioxidant

- Q: and what type of macromolecule are they made of? thanks!

- A catalyst is any substance that speeds up a chemical reaction without otherwise changing the outcome of the reaction. Catalysts do this by lowering a reaction's activation energy (which is the energy barrier that must be overcome before the reaction can proceed spontaneously). Catalysts are not permanently changed by the reactions they catalyze, so one catalyst could reasonably catalyze the same reaction many times over. Enzymes are biological catalysts because they lower the activation energy of metabolic reactions (and therefore increase their rate). Every enzyme has an active site that is specific for a particular substrate, or for a small related group of substrates. When the correct substrate binds to the active site, the enzyme catalyzes a particular reaction and releases new products. Substrates that don't match the shape of the enzyme's active site usually won't be affected by the enzyme. Enzymes are proteins, which are in turn polymers of amino acids. The sequence of amino acids in an enzyme, as well as the three-dimensional structure of the polypeptide chain, are essential for determining the enzyme's functionality. I hope that helps. Good luck!

- Q: My chemistry teacher wont tell me because it's in the higher course. And i'm not waiting a whole year to find out. And also, google is being a gimp about it. So thanks a lot if you know, I only have basic chemistry knowledge btw, lumen'ss terms if you can.

- Catalysts facilitate the reaction. They might work in several ways. Here is an example: Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process regenerating the catalyst. The following is a typical reaction scheme, where C represents the catalyst, X and Y are reactants, and Z is the product of the reaction of X and Y: X + C → XC (1) Y + XC → XYC (2) XYC → CZ (3) CZ → C + Z (4) Although the catalyst is consumed by reaction 1, it is subsequently produced by reaction 4, so for the overall reaction: X + Y → Z They might also just increase the surface area, thus speeding up the reaction. Example: Coke looses its fizz over time if left with the cork unscrewed. This is because the HCO3 is released as CO2. If you drop a menthos into the coke, it explodes with CO2, because the methos is full of tiny dents in the surface (thus giving it a massive surface area). (i blatantly copied the first example from the wiki)

- Q: The chemical reaction equation of methanol heating and oxygen in the presence of catalyst

- Catalytic oxidation of formaldehyde

- Q: Can chemical reaction limits be changed by catalyst or other methods?

- Do not know what you say is the limit of the concept of reaction. The general catalyst can change the rate of the reaction, most of which is used to speed up the reaction rate, that is, it will be difficult to react or normally does not respond to the material to provide a reaction of the bridge, so that the material through the catalyst to establish a connection to achieve the reaction the goal of.

- Q: Why can some catalysts be reused in (chemistry)?

- Because the catalyst in the chemical reaction before and after the quality and chemical properties have not changed, so in the chemical reaction can be reused.

- Q: What are the methods of catalyst characterization?

- Physical means, is commonly used detection means, infrared, ultraviolet, electron microscopy, X-ray diffraction, nuclear magnetic, etc., of course, including a variety of conventional inability analysis.

- Q: put in a way that a freshman in high school can understand please =)

- enzymes are biological catalysts catalysts and enzymes speed up a reaction without being used up

- Q: If possible can anyone give me information on the active site, substrates, products, and the energy of activation as part of the answer?Responses greatly appreciated! Thankss! 10pts to best answer!

- Catalysts help shift the equilibrium of a reaction to one that is more favorable. They allow a naturally occurring reaction that may be extremely slow to progress faster or an unfavorable reaction to proceed forward. During the process catalysts are recycled, which means that at the catalyst is the same compound in the beginning and the end of the reaction, although during intermediate steps catalysts can change conformation. Catalysts shift the equilibrium of a reaction by lowering the activation energy of a reaction, which is the energy barrier which must be overcome in order for the reaction to proceed in a desired direction. This can be achieved in several ways such as providing favorable thermodynamic conditions for a reaction or creating intermediates which react more favorably to create the products. Inside the cell a lot of chemical reactions are either too slow to proceed naturally or are simply unfavorable. Catalysts help overcome those barriers. The substrate is the part of the reaction which gets transformed into the products after binding to the active site of the protein.

Send your message to us

Hydroxypropyl Methyl Cellulose from CNBM Manufacture

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords