Hybrid Stepper Servo Motor Hs421 (42mm, 2Phase)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2500 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

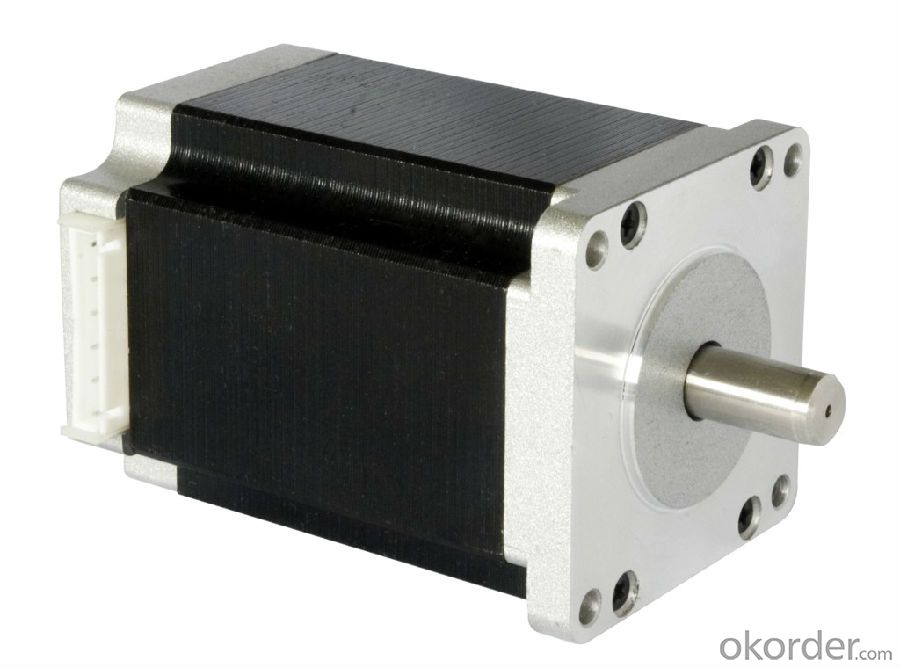

Hybrid Stepper Servo Motor Hs421 (42mm, 2Phase)

Product Details

Basic Info.

Model NO.:HS421(1.8degree )42mm-2 Phase

Excitation Mode:HB-Hybrid

Type:Magnetic-Electric

Size:42mm

Speed:0-3000rpm

Resistance:100min 500VDC

Tem.:0-55

Export Markets:Global

Additional Info.

Trademark:I. CH

Standard:CE, RoHS, nqa

Origin:Nanjing China

Production Capacity:50, 000PCS/Year

Product Description

I.CH Motion Hybrid Stepper Servo Motor HS421

General Specifications

Speed:0-3000RPM

Insulation Resistance:100MIN,500VDC

Ambient Temperature:(0-55ºC

Encoder lines:2500/1000

| Electrical Specification | ||||||||

| Series Model | Rated Voltage (V) | L (mm) | Phase Current (A) | Phase Resistance (Ω) | Phase Inductance(mH) | Holding Torque (N.cm) | Moment of Inertia (g.cm2) | Motor Weight ( g) |

| HS421-05013A | 4.16 | 51 | 1.3 | 3.2 | 5.5 | 50 | 77 | 530 |

| HS421-05023A | 2.3 | 51 | 2.3 | 1.0 | 1.9 | 50 | 77 | 530 |

| HS421-05613A | 4.94 | 67 | 1.3 | 3.8 | 8.5 | 56 | 115 | 670 |

| HS421-07023A | 3.22 | 67 | 2.3 | 1.4 | 3.1 | 70 | 115 | 670 |

- Q: What are the advantages and disadvantages of stepping into the motor?

- The disadvantages of stepping into a motor are as follows: If the control is not easy to generate resonance; It is difficult to operate at a high speed. It's difficult to get a big torque There is no advantage in volume weight, low energy utilization. More than the load, the synchronization will be broken, and vibrations and noise will be emitted at high speed.

- Q: What is the principle of the three-phase six-step motor?

- The step motor is an open loop controlling element which converts the electrical pulse signal into angular displacement or line displacement. In the case of the overload, motor speed, stop position depends only on the pulse signal frequency and pulse number, and not affected by load change, when the stepper driver receives a pulse signal, it is driving a stepper motor according to set the direction of a fixed Angle, known as the "step Angle", its rotation is based on the Angle of the fixed step by step. It can control the amount of angular displacement by controlling the number of pulses, so as to achieve accurate positioning. At the same time, the speed and acceleration of the motor can be controlled by controlling the pulse frequency to achieve the goal of speed adjustment.

- Q: How big is the minimum step motor? How big is the motor?

- The step motor in the electronic watch is basically the smallest and can only drive a few gears and pins.

- Q: Why can't the stepping motor speed go up?

- Increase motor speed: drive current in the step motor drive. Precise positioning control: calculate the number of steps in the top machine or PLC.

- Q: How to control the step motor with s7-200, how to control the yield to the motor, how to stop?

- The pulse output and direction of 200PLC are not related. You can see it from the number of pulses that you want to see from >. You can write the direction control program in front of the PLS command and immediately.

- Q: Is the torque characteristic characteristic of the step motor? Does the servo motor have a moment characteristic curve?

- The moment frequency characteristic is not unique to the step motor. All motors have a relationship between the input frequency and the output torque. This is the relationship between the value of the output torque at different input frequencies. For stepping motors, however, the output torque decreases rapidly as input increases frequently. In engineering, the design and application of this characteristic of the motor is brought to the attention of design and application. The project is to ensure that the torque must meet the requirements at any speed. Both: stepper motor input frequency, the output torque of the punctuation, must fall on the rotational speed of shaft torque frequency graph, the frequency axis, characteristic curve, within the scope of the surrounding to work properly. Other motors (e.g., servo motors), because in a very large speed range, the output torque varies little, which is what we call constant torque output. This is the main difference between stepping motor and other motors in design and usage. It is also one of the main disadvantages of stepping motor in performance.

- Q: How do you calculate the inertia and torque on the output shaft of the motor

- The step motor is an open loop controlling element which converts the electrical pulse signal into angular displacement or line displacement. In the case of the overload, motor speed, stop position depends only on the pulse signal frequency and pulse number, and not affected by load change, when the stepper driver receives a pulse signal, it is driving a stepper motor according to set the direction of a fixed Angle, known as the "step Angle", its rotation is based on the Angle of the fixed step by step. It can control the amount of angular displacement by controlling the number of pulses, so as to achieve accurate positioning. At the same time, the speed and acceleration of the motor can be controlled by controlling the pulse frequency to achieve the goal of speed adjustment. Stepper motor is a kind of induction motor, its working principle is the use of electronic circuit, direct current (dc) into time-sharing power supply, multiphase sequential control current, in this current for stepper motor power supply, step motor to work properly, is time-sharing power supply for step motor drive, multiphase timing controller. Although the stepping motor has been widely used, the step motor is not used as a normal dc motor and ac motor is used regularly. It must be used by the control system such as double ring pulse signal and power drive circuit.

- Q: What is the difference between the step motor two phase eight and four phase eight lines?

- Four phase eight steps to the motor connection: F1, F2, excitation source, H1 and C1 wired together, H2, C2 dc power supply. If you need to reverse the inversion, you simply need to change the wiring: you can connect the H1 and C2, H2, and C1 to the dc power supply

- Q: How to control step motor? I'm going to make a smart blinds to stop the motors

- Motor head need to stop the travel switch can be used in control, motor speed is slow, can the wheels of the motor shaft with a freshman, the wheels with other devices can be used in.

- Q: What is the speed of the step motor that is controlled by?

- Stepper motor rotation speed is controlled by pulse, a turn is 360 degrees, 1.2 degrees such as a pulse rotation, then, a circle of 300 pulse. Usually has a dedicated stepper motor drives, drives a current, such as segmentation set. About stepping motor subdivision, stepping motor subdivision.

Send your message to us

Hybrid Stepper Servo Motor Hs421 (42mm, 2Phase)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2500 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches