hrc hot rolled steel coil crc cold rolled steel coil galvanized steel coil ppgi ppgl

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

We supply ms equal & unequal angle bar, channel bar,jis channel, upn, steel i beam,h beam, ipe, ipeaa, steel sheet pile, flat bar, hollow section, tmt bar, wire rod, binding wire, wire mesh, hrc, CRC, gi coil, ppgi, roofing sheet, chequered coil & plates, medium plate, scaffolding systems, prefabricated container houses etc. Also for metal & steel processing.

If you are in the market for any steel products, please feel free to contact us.

| Product Name | Hot Rolled Steel Coil/Rolls |

| Standard | ASTM, AISI, GB, JIS, DIN, BS,En |

| Grade | ASTM A36/A36M-08,JIS G3101-2004,EN 10025-2,GB/T 700-2006,DIN 17100-80,BS 4360-90 |

| Thickness | 0.12-12mm or customized as required |

| Width | 600-2000mm or customized as required |

| Surface Treatment | black/ galvanized/ coat /oiled /painting,etc |

| Coil Weight | 3-20 Tons or customized as required |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Technique | Hot Rolled/Cold Rolled |

| Sample | Sample Freely |

| Type | Steel Coil, Hot Rolled Steel Sheet |

| OEM Service | Perforated, Cutting special size, Doing flatness, Surface treatment, etc |

| Certifications | MTC,ISO,SGS,BV |

| Transport Package | Export Standard Package or as Request |

| Payment terms | T/T,L/C |

| Loading Port | Tianjin/Qingdao/Shanghai Port |

| Application | Widely used in shipbuilding, automobiles, bridges, construction, machinery, pressure vessels and other manufacturing industries. |

| Export market | Europe, Africa, Central Asia, Southeast Asia, Middle East, South America, North America, etc |

Hot sale SPCC cold rolled steel coil/CRC/cold rolled coil/ Cold rolled steel sheet

Product Description

Standard | GB | JIS | EN | DIN |

Q195 | SPCC | DC01 | ST12 | |

Q235 | SPCD | DC03 | ST13 | |

Q345 | SPCE | DC04 | ST14 | |

SPCF | DC05 | ST15 | ||

SPCG | DC06 | ST16 |

| Classification | Designation | Characteristics | Main applications |

| Commercial quality | SPCC,SPCCT | Commercial quality suitable for bending fabrication and simple forming; this is thetype in greatest demand. | Refrigerators, cabinets, power distribution baords and drums. |

| Drawing quality | SPCD | Drawing quality second only tothat of SPCEN. Excellent uniformity. | Automobile floor and roof panels. |

| Deep-drawing quality | SPCE,SPCF | Deep-drawing quality.With metallurgically controlled grain size, it retains its beautiful finish even after being deep-drawn. | Automobile fenders and quarter panels |

| Extra deep-drawing quality | SPCG | Extra-low-carbon steel sheets with highest workability | Automobile internal panels and deep-drawn parts |

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

SPCC | ≤0.12 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

SPCD | ≤0.10 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

SPCE | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

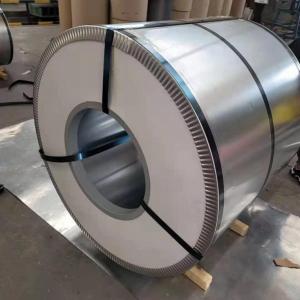

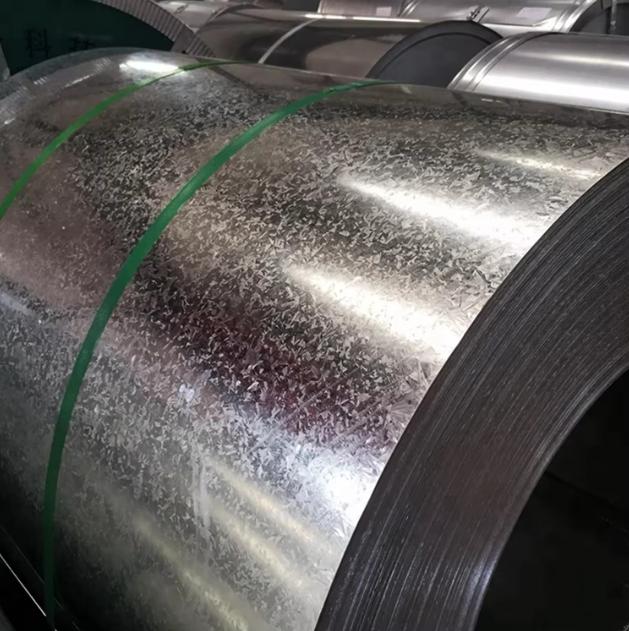

| Commodity | Galvanized Steel Coil |

| Techinical Standard | JIS ASTM AISI BS DIN GB |

| Grade | Q195,Q235,Q345,DX51D ,SGCC SGCH DC51D SGH340 |

| Types | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 600-1500mm |

| Thickness | 0.15-5mm |

| Length | 3-12m or as your requirements |

| Type of coating | galvanized |

| Zinc coating | 20-275g/m2 |

| Surface treatment | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint (non) Chromated,(un)Oiled,Zero spangle,Minimized spangle, Regular spangle, Skin-passed,Non skinpassed |

| Coil ID | 200mm/500mm/508mm or 610mm |

| Coil weight | at your request |

| Package | Properly packed for ocean freight exportation in 20''containers |

| Application | Industrial panels, roofing and siding for painting |

| Price terms | FOB,CFR,CIF |

| delivery time | 10~15 days after confirmed order |

| Remarks | 1.Insurance is all risks 2.MTC will be handed on with shipping documents 3.We accept the third party certification test |

- Q: What are the different methods of punching steel coils?

- For punching steel coils, there are several methods available that vary depending on specific requirements and desired outcomes. The following are some commonly used methods: 1. Mechanical Punching: To create holes in the steel coil, a mechanical press is employed. This method involves utilizing a punch and die set, where the coil is subjected to force from the punch to create the hole. Mechanical punching is best suited for small to medium-sized holes and finds frequent use in high-volume production settings. 2. Hydraulic Punching: In hydraulic punching, hydraulic pressure is utilized to drive the punch into the steel coil. This method is commonly employed for punching larger holes or shapes that demand greater force. Hydraulic punching machines offer precise control and can handle thicker and harder materials. 3. Laser Cutting: Laser cutting is a non-contact technique that employs a laser beam to cut through the steel coil. By directing a focused laser beam onto the coil, the material is melted and evaporated to form the desired shape or hole. Laser cutting provides high precision and can be used for complex shapes and patterns. 4. Plasma Cutting: Plasma cutting involves the use of a high-velocity jet of ionized gas (plasma) to melt and remove the steel coil material. This method is suitable for cutting thicker steel coils and is often employed for larger holes or irregular shapes. 5. Waterjet Cutting: Waterjet cutting uses a high-pressure jet of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can effectively cut various materials, including steel. Waterjet cutting is renowned for its high precision and clean cuts. Each method of punching steel coils possesses its own advantages and considerations. Factors such as material thickness, desired precision, production volume, and cost will determine the most suitable method for a specific application.

- Q: Can a steel at 0.0055 of thickness still be powerful enough to bash skulls? As well as stop handgun cartridges or at least weaken them?You see, i had an idea of making a cylindrical Knuckles made from steel. By my dimensions, 5in diameter, 12 inch h1 and 15 in h2. Half-Sphere: a sphere that is cut in half for the dome at the fist:( [ pi x ( d ^ 3) ] / 6 ) / 2Cylinder

- I don't follow your calculations. It seems to me that the piece you show could be made from .01 steel and still be less than a pound. Also, it is hard to get steel thinner than .015 because anything thinner is not very useful. If you made it out of .015 steel and used a high strength steel, it might be useful. You wouldn't be bashing any skulls, but with some spikes on the end, it could do some damage, and protect against knives or other hand weapons. You also won't get any bullet resistance out of anything that thin. If you want to bash skulls and deflect bullets, you have to get up to at least .10 and several pounds. Any weight on your hands slows down the speed of your punch, but this is compensated for by the increased energy of impact carried by the extra mass. Also, having something hard to protect your hands allows for harder hits and more damage to the opponent. An interesting idea, but it would take some testing to figure out the optimum configuration. One problem I see is that it completely encloses the hand, making it impossible to use the hand for anything else. So you would have to put it on and take it off a lot, and there would be cases where you wouldn't be able to put it on when you needed it. For that reason, I would not wear two at one time. I would make it heavier and wear it on one hand for bashing skulls and deflecting weapons, and keep the other hand free for other things.

- Q: How are steel coils used in the manufacturing of transportation equipment?

- Steel coils are used in the manufacturing of transportation equipment as they provide a durable and strong foundation for various components such as chassis, frames, and body panels. These coils are typically processed and shaped into specific forms to meet the design requirements of automobiles, ships, trains, and aircraft. The high tensile strength and ability to withstand heavy loads make steel coils an essential material in the transportation industry, ensuring the safety and reliability of the vehicles and equipment.

- Q: i mean cor ten steel( rusted)

- Bill summed it up pretty quick and provided a link. For some reason you are focusing on the copper content when it really is insignificant in the overall picture of the sun hitting its surface. If you could elaborate more, maybe we could offer a better answer.

- Q: How are steel coils used in the production of steel drums?

- Steel coils are used in the production of steel drums as they are unrolled and shaped into cylindrical forms to create the body of the drum. These coils are cut, welded, and sealed to form a solid and durable structure, which serves as a container for storing and transporting various materials such as liquids, chemicals, and even food products.

- Q: What are the various surface finishes available for steel coils?

- Steel coils offer a range of surface finishes, each with its own properties and uses. Some commonly used finishes include: 1. Hot rolled: Steel is rolled at high temperatures, resulting in a rough surface. This finish is great for structural applications like construction materials and industrial machinery. 2. Cold rolled: Steel is rolled at room temperature, creating a smoother surface. It is commonly used in automotive and appliance manufacturing due to its superior finish and accuracy. 3. Galvanized: Steel is coated with zinc to protect against corrosion. Galvanized coils have a shiny appearance and are suitable for outdoor applications such as roofing and fences. 4. Electro-galvanized: Coated with a thinner layer of zinc through an electroplating process, these coils offer good corrosion resistance. They are commonly used in electrical appliances, automotive parts, and construction. 5. Pre-painted: Coated with paint or polymer film, pre-painted coils provide both corrosion protection and aesthetic appeal. They are extensively used in construction for roofing, cladding, and wall panels. 6. Stainless steel: Stainless steel coils have unique properties, including corrosion resistance, heat resistance, and chemical damage resistance. They are ideal for industries like food processing, medical equipment, and marine applications. These examples showcase the variety of surface finishes available for steel coils. The choice of finish depends on factors such as the intended use, desired appearance, and level of corrosion resistance required.

- Q: The length of a steel beam increases by 0.78 mm when its temperature is raised from 22 degrees C to 35 degrees C. What is the length of the beam at 22 degrees C (in meters)?I used: L = (0.78 mm)/[(9/5)(.00000645 F)(13)] = 5.17 meters but Mastering Physics said Not quite. Check through your calculations; you may have made a rounding error or used the wrong number of significant figures. I'm confused because this is how we learned this kind of problem in class, so if anybody knows what I did wrong, feel free to correct my errors! Thanks

- the welded joints,...are then sturdy steel, and conducts warmth very very right this moment, so develop from warmth often is the comparable because of fact the plate steel around it. you may desire to slope the backside and have a condensate seize gadget, steam secure practices stress alleviation valve, sized for the quantity and pressures, totally lag the vessel, adhere to ALL secure practices specs., (of your codes), which comprise the welding NDT. in the tank layout enable for the thermal develop of the vessel. cheers.

- Q: How are steel coils inspected for hardness using hardness testers?

- To assess the strength and durability of steel coils, hardness testers are employed to examine their hardness. Hardness testers are specialized devices used to gauge a material's resistance to indentation or penetration. For steel coils, Rockwell or Brinell testers are commonly utilized. Both methods entail exerting a precise force onto the surface of the coil and measuring the depth of indentation or size of the impression made. In the case of Rockwell testing, a steel ball or diamond cone is pressed onto the coil's surface with a predetermined force. The depth of penetration is then measured and compared to a standardized scale in order to determine the hardness value. Different scales are employed based on the size and type of indenter in use. On the other hand, Brinell testing involves using a spherical indenter made of tungsten carbide or hardened steel. This indenter is pressed onto the coil's surface with a known force, and the resulting indentation is measured and compared to a standardized table to determine the hardness value. Both methods provide a quantitative measure of the steel coil's hardness, which serves as an indicator of its ability to resist deformation, wear, and cracking. The hardness test results are subsequently utilized to ensure that the steel meets specific quality standards or customer requirements. It is important to note that the inspection process may involve sampling, where representative sections of the steel coil are tested, or it may involve testing the entire coil, depending on the specific inspection requirements. Additionally, accurate and reliable results necessitate proper calibration and maintenance of the hardness testers.

- Q: So we all know a 1000lb steel ball will sink in water, but if you were to leave the center of the ball hollow and fill with air, if the steel ball was big enough in diameter it should float correct? What size would the steel ball need to be to float?

- specific gravity of a steel is approximately 7.82 as compared to water. so, the hollow sphere(filled with air) is having volume more by 7.82 as compared to solid sphere, then the 1000 lb hollow steel ball float in the water (Why Do Ships Float? The Greek Mathematician and inventor Archimedes lived during the 3rd century BC. According to history he was in the bath one day when he discovered the principle of buoyancy which is the reason why huge Greek ships weighing thousands of pounds could float on water. He noticed that as he lowered himself into the bath, the water displaced by his body overflowed the sides and he realised that there was a relationship between his weight and the volume of water displaced. It is said that he ran naked into the street yelling heurEka which is where we get our word eureka! (I found it), Greek heurEka I have found, from heuriskein to find. The Buoyancy Principle: Archimedes continued to do more experiments and came up with a buoyancy principle, that a ship will float when the weight of the water it displaces equals the weight of the ship and anything will float if it is shaped to displace its own weight of water before it reaches the point where it will submerge. This is kind of a technical way of looking at it. A ship that is launched sinks into the sea until the weight of the water it displaces is equal to its own weight. As the ship is loaded, it sinks deeper, displacing more water, and so the magnitude of the buoyant force continuously matches the weight of the ship and its cargo.)

- Q: I have taylormade burner steel irons and I was wondering what would the flex of steel be if you were to compare it to graphite shafts, like regular, stiff, super stiff, etc...THANKS!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- If i understand you correctly, i think you misunderstand shafts. Steel shafts vs. graphite shafts these days is more of a competition of weights, not flexibility. Both steel and Graphite have different flex profiles available from Ladies (L) to super stiff (X). Graphite may feel a little more whippy than steel because of the lighter weight. Shafts will vary by company as well. Stiff from True temper may not be as stiff as one from Aldila, or vice verse. You can also make a shaft play stiffer or more flexible by where you cut the length. This is called tipping. Take more from the bottom and it will be stiffer, more from the grip end and it will play more flexible.

Send your message to us

hrc hot rolled steel coil crc cold rolled steel coil galvanized steel coil ppgi ppgl

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords