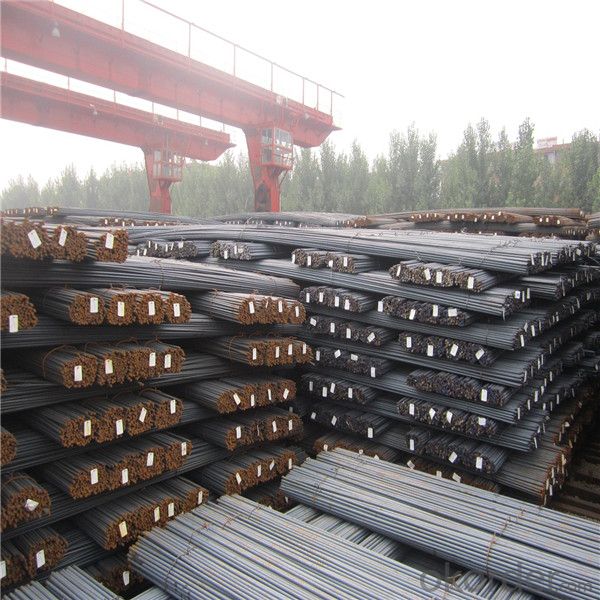

HRB400 Deformed Steel Rebar hot sale for constraction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Reinforcing bars, steel rebar is metal bars often used in construction for pouring concrete or supporting walls

and columns. The rebar can be smooth, though they are frequently manufactured with deformations that create

greater texture to which concrete can adhere, creating a stronger bond that helps prevent cracking of concrete.

These deformations do not create weaknesses in the rebar, and when rebar is measured to determine its diameter,

it is typically measured at the narrowest point. Strength grades indicate the amount of pressure the steel rebar can

withstand, and grade and diameter are typically presented in both imperial and metric units

Our Advantage: High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: Can steel rebars be used in reinforced masonry construction?

- Yes, steel rebars can be used in reinforced masonry construction. They are commonly used to strengthen and reinforce the masonry walls, providing additional strength and resistance to cracking or structural failure. The rebars are typically embedded within the masonry mortar joints or placed vertically within the cells of concrete masonry units to enhance the overall structural integrity of the construction.

- Q: What is the role of steel rebars in preventing concrete spalling due to fire?

- Steel rebars play a crucial role in preventing concrete spalling due to fire by providing reinforcement and structural integrity to the concrete. When exposed to high temperatures during a fire, concrete can undergo thermal expansion, which can lead to cracking and spalling. However, the presence of steel rebars helps to restrain the expansion and prevent the concrete from breaking apart. The rebars act as a reinforcement, distributing the stresses caused by the heat and preventing the concrete from failing under the extreme conditions. Overall, steel rebars enhance the fire resistance of concrete structures and help maintain their structural integrity during a fire event.

- Q: Are there any specific guidelines for handling and placing steel rebars in concrete?

- Yes, there are specific guidelines for handling and placing steel rebars in concrete. These guidelines include proper storage and handling of rebars to prevent damage, ensuring proper placement and spacing of rebars according to engineering drawings and specifications, and using appropriate tools and techniques for tying and securing the rebars in place. Additionally, it is important to follow best practices for concrete pouring and compaction to ensure proper bonding between the rebars and the concrete. Compliance with these guidelines is crucial to ensure the structural integrity and durability of the concrete structure.

- Q: What is the maximum length of steel rebars that can be used in construction?

- The maximum length of steel rebars that can be used in construction varies depending on the specific project and structural requirements. However, standard lengths for steel rebars typically range from 6 meters (20 feet) to 12 meters (40 feet).

- Q: How do steel rebars affect the acoustic properties of a structure?

- Steel rebars have a minimal impact on the acoustic properties of a structure. Due to their high density and stiffness, rebars can slightly improve the sound insulation capabilities of a building by reducing sound transmission through walls and floors. However, their influence on other acoustic aspects, such as reverberation or sound absorption, is negligible.

- Q: How do steel rebars contribute to the strength of concrete?

- Steel rebars contribute to the strength of concrete by providing reinforcement and increasing its tensile strength. The rebars are embedded in the concrete, forming a strong bond between the two materials. This helps to distribute the load evenly and prevent cracks or fractures from forming, making the concrete structure more resistant to bending, shearing, and other external forces.

- Q: Can steel rebars be used in infrastructure projects?

- Yes, steel rebars can be used in infrastructure projects. They are commonly used in construction projects to reinforce concrete structures such as bridges, buildings, and highways. Steel rebars add strength and durability to the concrete, making it capable of withstanding heavy loads and harsh environmental conditions.

- Q: How are steel rebars protected from rusting during storage?

- Steel rebars are protected from rusting during storage by applying a coating of corrosion-resistant material, such as epoxy, zinc, or paint. This protective layer acts as a barrier, preventing moisture and oxygen from coming in contact with the steel surface, thus reducing the risk of rust formation. Additionally, rebars are often stored in dry and controlled environments to minimize exposure to humidity, which further helps to prevent rusting.

- Q: What is the role of steel rebars in column construction?

- Steel rebars play a crucial role in column construction as they provide reinforcement and strength to the concrete structure. By adding rebars to the concrete, columns become more resistant to bending, cracking, and structural failure. Rebars help transfer the load from the structure to the foundation, improving overall stability and durability. They also help control and minimize the effects of shrinkage and temperature variations. In essence, steel rebars enhance the structural integrity of columns, ensuring they can withstand the desired load and maintain their shape over time.

- Q: Can steel rebars be used in structures with aggressive chemical exposure?

- Steel rebars can be used in structures with aggressive chemical exposure, but their performance may be compromised depending on the specific chemicals involved. It is crucial to select the appropriate type of steel with corrosion-resistant properties or use protective coatings to prevent degradation and maintain structural integrity. Additionally, regular maintenance and monitoring are required to ensure the rebars' durability in such environments.

Send your message to us

HRB400 Deformed Steel Rebar hot sale for constraction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords