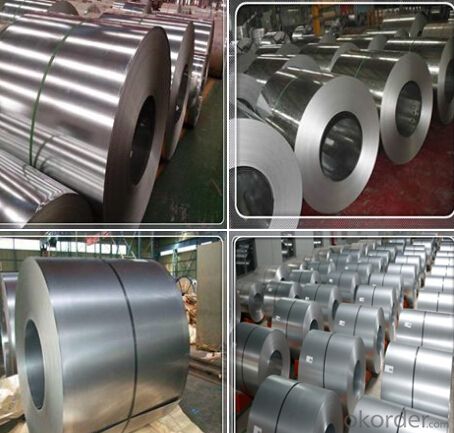

Hot Selling Cold Rolled 304 Stainless Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

description:

Model NO.:304 stainless steel coil

Type:Stainless Steel Coil

Shape:Round

Grade:201/202/301/303/304/304L/316/316L/321/310S/401/409

Certification:ISO, SGS, BV, RoHS, IBR, AISI, ASTM, GB, EN, DIN, JIS

Perforated:Not Perforated

Standard:ASTM, AISI, GB, JIS, DIN, EN

Technique:Cold Rolled

Surface Treatment:2b, Ba,No.1,No.2e,No.2D,No.3,No.4,Hl

Thc:0.3-2.0mm

Width:1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm

Treatment:2b, Ba,No.1,No.2e,No.2D,No.3,No.4,Hl

Material:201/202/301/303/304/304L/316/316L/321/310S/401/409

Application:Foodstuff, Gas, Metallurgy, Biology

Export Markets:Global

| Product | Stainless Steel Coil |

| Grade | 201/202/301/303/304/304L/316/316L/321/310S/401/409/410/ 420J1/420J2/430/439/443/444 |

| Surface Finish | 2B, BA,NO.1,NO.2E,NO.2D,NO.3,NO.4,HL,8K |

| Technique | cold rolled |

| Certification | ISO,DNV,SGS,CE |

| Standard | JIS/GB/DIN/ASTM/AISI/EN |

| Thickness | 0.16-2.0mm |

| Length | 2000mm-6000mm or as customer request |

| Width | 1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm |

| Supply Ability | 5000mt Per Month |

| Minimum Order Quantity | 2t |

| Type | Coil |

| Application | Foodstuff, gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy Medical equipment, fertilizer, etc. |

| Shipment Terms | FOB CIF CFR |

| Acid and Corrosion Resistance | High-strength steel |

| Packaging Detail | Standard Export Seaworthy Package |

| Delivery Detail | 0~30days after order |

| Payment Terms | T/T L/C |

- Q: What are some of the greatest steel guitar songs in the history of country music. Western swing applies also.

- Bob okorder /

- Q: What are the common quality control measures for steel coils?

- Some common quality control measures for steel coils include inspection for surface defects such as scratches, dents, or unevenness, checking for dimensional accuracy and thickness consistency, testing for mechanical properties such as tensile strength and hardness, conducting chemical composition analysis, and ensuring proper packaging and labeling of the coils.

- Q: How are steel coils used in the production of steel wire?

- Steel coils are used in the production of steel wire by being unwound and fed into a wire drawing machine. The coils provide a continuous and consistent supply of steel, which is passed through a series of dies to reduce its diameter and increase its strength. This process is repeated multiple times until the desired wire diameter is achieved.

- Q: How are steel coils used in the manufacturing of steering systems?

- Steel coils are commonly used in the manufacturing of steering systems as they provide the necessary strength and durability required for various components such as steering racks, tie rods, and control arms. The steel coils are typically shaped, formed, and processed to create these parts, ensuring stability, precision, and reliability in steering mechanisms.

- Q: Hello people.Me and the life mate have been working on a fantasy book together and we are currently in the process of outlining the cultures. The culture of our antagonists' is a sort of woodland tribal/celtic[ish] deal and they are very nature oriented. Being a detail freak and wanting to have some real world credibility in the story, I am trying to decide how they produce steel. I want steel to be an important part of the culture, but a thing that is in limited supply. I also do not want there to be a large amount of resources committeded to mining or processing iron ore for steel. So does anyone have any real world ideas explaining how the people can produce steel without using underground mining operations, large processing facilities, and without raping the land?All help and ideas are appreciated

- Well, steel is just modified iron, so you're going to have to start with acquiring the iron first. For that, you're most likely going to be using some sort of underground mining somewhere - either they do that themselves, or they purchase the iron elsewhere. Assuming you're not dealing with meteoric iron (which is possible, but pretty uncommon), or iron sands (not likely in a woodland area), then unless you're dealing with a rocky outcropping with iron veins out in the open, I'm pretty sure there needs to be somebody doing some digging. That said, it doesn't need to be a full raping of the land scenario. A couple of minor mines, some small-scale smelting operations, and somebody knowing the secret of making steel, and it could give you small amounts of steel without making an ecological disaster.

- Q: What are the dimensions of steel coils used in the electrical equipment industry?

- The dimensions of steel coils used in the electrical equipment industry can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry range from 0.25mm to 3mm in thickness and 600mm to 2000mm in width. The inner diameter of the coil is typically around 508mm, while the outer diameter can vary from 800mm to 2000mm. These dimensions ensure compatibility with various electrical equipment manufacturing processes and enable efficient production.

- Q: How are steel coils used in the manufacturing of medical equipment?

- Steel coils are commonly used in the manufacturing of medical equipment as they serve as a crucial component in various applications. These coils are often employed in the construction of medical devices such as surgical instruments, orthopedic implants, and diagnostic equipment. The high strength and durability of steel make it ideal for these purposes, ensuring the longevity and reliability of the medical equipment. Additionally, steel coils are used in the production of medical furniture, such as hospital beds and examination tables, providing stability and support. Overall, steel coils play an essential role in the manufacturing of medical equipment, contributing to the quality and functionality of these devices.

- Q: What are the characteristics of hot-rolled steel coils and cold rolled steel coils? What loading and unloading tools should be used? What items should be paid attention to?

- Steel is usually stable in performance. One thing is that the environment should be dry, not rain, because the damp environment is easy to rust. As long as it's in a dry room, it's basically no problem.

- Q: What are the common coil inspection techniques?

- Common coil inspection techniques include visual inspection, magnetic particle inspection, eddy current testing, ultrasonic testing, and radiographic testing.

- Q: I know you can still but steel core ammo. I have read that it IS Armor Piercing (AP) and I have read it is not. Which is true? I am not looking for its AP capabilities. I want it if it is or is not AP. I live in Oklahoma. I need to know if it legal for me to purchase it in this state; and where can i get it? I am over 18, not a felon, etc. I have seen it sold online in Oklahoma years ago, but have read it is and isn't legal to purchase here. I am looking for 7.62x39 steel core for an SKS. If anyone knows where or how to get some, please let me know, if it's legal. Thanks.

- You can legally buy chinese steel core and 855 5.56 which is also steel core. That's on the federal level. I don't know about your state in particular but ammo peircing ammo is illegal but there are different grades of steel. If that were the case I couldn't buy Bugarian steel cased light ball in 7.62x54R.

Send your message to us

Hot Selling Cold Rolled 304 Stainless Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords