Hot sell API Seamless Pipe from CNBM International Corporation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

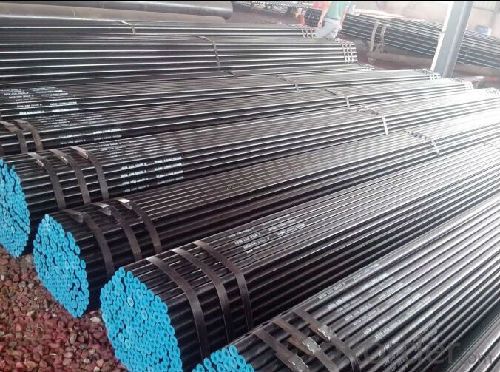

1、Structure of Hot sell API Seamless Pipe from CNBM International Corporation:

API Seamless Pipe is used for construction of long distance pipelines for combustible liquids and gases, nuclear station pipelines, heating system pipelines, general-purpose pipelines, vessels manufacturing, mechanical engineering and instrumental engineering.

2、Main Features of Hot sell API Seamless Pipe from CNBM International Corporation:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

3、Hot sell API Seamless Pipe from CNBM International Corporation Images:

Packaging & Delivery

| Packaging Details: | seaworthy package, bundles wrapped with strong steel strip |

| Delivery Detail: | 15-30 days after received 30% TT |

4、Hot sell API Seamless Pipe from CNBM International Corporation Specification:

Standard: GB, DIN, ASTM

ASTM A106-2006, ASTM A53-2007

ASME, ASTMGrade: 10#-45#, 16Mn

10#, 20#, 45#, 16Mn

20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53BThickness: 2 - 50 mm Section Shape: Round Outer Diameter: 21.3 - 620 mm Secondary Or Not: Non-secondary Application: Hydraulic Pipe Technique: Hot Rolled Certification: API Surface Treatment: factory state or painted black Special Pipe: API Pipe Alloy Or Not: Non-alloy Length 6-12M 1.Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2.Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3.Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4.Surface:black lacquered,varnish coating or galvanized.

5.Ends:Beveled or square cut,plastic capped,painted.

6.Packing:bundles wrapped with strong steel strip,seaworthy packing.

5、FAQ of Hot sell API Seamless Pipe from CNBM International Corporation

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

Any question, pls feel free to contact us !

- Q: What are the different methods of pipe cutting for steel pipes?

- There exists a variety of techniques for cutting steel pipes, each tailored to specific circumstances and demands. Some of the most prevalent techniques are as follows: 1. Manual Pipe Cutters: These handheld tools are frequently employed for cutting smaller steel pipes. They typically feature a rotating cutting wheel that gradually creates a groove until the pipe is severed. Portable and relatively user-friendly, manual pipe cutters are suitable for on-site cutting tasks. 2. Hacksaw: The use of a hacksaw is a traditional and cost-effective means of cutting steel pipes. This method requires physical exertion and time; however, it can effectively cut pipes with smaller diameters. It is crucial to use a fine-toothed blade and apply steady pressure to ensure a clean and precise cut. 3. Reciprocating Saw: Also known as a sawzall, the reciprocating saw is a power tool that employs a back-and-forth cutting motion to swiftly and efficiently cut through steel pipes. These versatile saws can accommodate different types of blades to handle various pipe sizes and thicknesses. 4. Band Saw: Band saws are commonly employed in industrial settings for the purpose of cutting large steel pipes. These saws feature a continuous loop of teethed metal blade that moves on wheels, enabling precise and rapid cutting. Band saws are ideal for cutting large-diameter pipes and can be operated manually or fully automated for high-volume cutting tasks. 5. Pipe Cutting Machines: Pipe cutting machines are often utilized to achieve precise and consistent cuts. These machines are designed to cut steel pipes swiftly and accurately, making them suitable for large-scale industrial applications. Depending on the machine and requirements, various cutting methods like abrasive cutting, flame cutting, or plasma cutting can be employed. It is important to note that the selection of a pipe cutting method depends on factors such as pipe diameter, thickness, location, precision requirements, and available resources. It is imperative to adhere to proper safety precautions when working with any cutting method to prevent injury or damage to the pipes.

- Q: What is the difference between steel pipes and PVC-M pipes?

- The main difference between steel pipes and PVC-M pipes lies in their material composition. Steel pipes are made of steel, which gives them higher strength and durability. They are commonly used for high-pressure applications and in areas where the pipes may be exposed to extreme conditions or corrosive substances. On the other hand, PVC-M pipes are made of polyvinyl chloride modified with certain additives to enhance their impact resistance and toughness. They are lightweight, easy to install, and resistant to corrosion, making them suitable for various applications, including water supply, irrigation, and drainage systems. While steel pipes offer superior strength, they are more expensive and require regular maintenance, such as anti-corrosion treatments. PVC-M pipes, on the other hand, are more affordable, require minimal maintenance, and can be easily joined using solvent welding or mechanical fittings. In summary, the choice between steel pipes and PVC-M pipes depends on factors such as the intended use, budget, and environmental conditions.

- Q: Will the steel tube dance?

- Pole dancer performing double pole dance performance is much higher than single pole dancing difficult, because not only refers to the double pole dance together the two pole dance, two people should pay attention to the dance and tube movement, if two people do not fit to dance moves and skills on the tube action, you jump you. I jump, that wasn't a real double pole dance, dance like a double tube. If the two dance movements and pipe movements are not good enough or not natural enough, they will destroy the effect of the whole dance and make the audience feel that the dance is chaotic and not beautiful, so it is better to see a single pole dance. But the dancer's double pole dance performance is good, more powerful than single pole dance, and more aesthetic and artistic.

- Q: How are steel pipes used in the construction of geothermal power plants?

- Steel pipes are used in the construction of geothermal power plants for various purposes. They are primarily used to transport and circulate the geothermal fluid, which carries the heat from the underground reservoir to the surface. These pipes are typically made of high-quality steel that can withstand the high temperatures and corrosive nature of the geothermal fluid. Additionally, steel pipes are used in the construction of injection wells, where cool water or other fluids are injected back into the reservoir to maintain pressure and sustain the heat extraction process. Overall, steel pipes play a crucial role in the efficient and reliable operation of geothermal power plants.

- Q: What is the density of steel pipes?

- The density of steel pipes fluctuates based on the particular grade and composition of the steel employed. On the whole, steel pipes generally possess a density of approximately 7.8 grams per cubic centimeter (g/cm³) or 7800 kilograms per cubic meter (kg/m³). It should be emphasized that this figure may undergo slight variations contingent upon factors such as the manufacturing technique and the specific alloy integrated into the steel.

- Q: How do steel pipes handle pressure surges?

- Steel pipes are known for their strength and durability, which allows them to handle pressure surges effectively. When pressure surges occur in a pipeline system, steel pipes have the ability to withstand and absorb the increased force without breaking or rupturing. The high tensile strength of steel provides resistance against the pressure exerted on the pipes, preventing them from deforming or collapsing under the sudden surge. Additionally, steel pipes have a high burst pressure rating, meaning they can withstand significant increases in pressure without failing. Furthermore, steel pipes are often designed with a thicker wall thickness, which adds to their ability to handle pressure surges. The thickness of the pipe walls helps to distribute the increased force evenly, minimizing the risk of localized stress and potential failure points. Moreover, steel pipes are commonly used in conjunction with fittings and valves that are specifically designed to handle pressure surges. These fittings and valves are made from similar materials, ensuring compatibility and maintaining the integrity of the pipeline system. Overall, steel pipes are well-suited for handling pressure surges due to their strength, durability, and ability to withstand high pressures. Their resistance to deformation, high burst pressure rating, and compatibility with specialized fittings and valves make them a reliable choice for applications where pressure surges may occur.

- Q: 25 of the steel pipe with 6 in charge of what is the difference?

- 25 of the steel pipe with 6 in charge of the difference:25 of the steel pipe refers to the DN25 tube, the outer diameter of 25mm; 6, in charge of refers to DN20 steel pipe, the outer diameter is 20mm.

- Q: What is the outer diameter of the steel tube?

- The diameter of a steel pipe refers to the diameter of the steel pipe. The specifications of the steel tube is normal with diameter (diameter and thickness) said, for example 100MM outer diameter and wall thickness of 5MM tube is marked with 100*5.

- Q: Are steel pipes resistant to impact?

- Yes, steel pipes are generally resistant to impact due to their strong and durable nature. They can withstand heavy loads and external forces, making them suitable for applications that involve high-pressure environments or potential impact scenarios.

- Q: How are steel pipes used in the construction of solar power plants?

- Steel pipes are commonly used in the construction of solar power plants for various purposes. They are primarily utilized for the installation of solar panel mounting structures, which require sturdy and reliable support systems. Steel pipes are also used for the construction of infrastructure such as frames, racks, and supports for the solar panels. Additionally, they are employed in the installation of water and coolant systems, as well as for the transmission of fluids and gases within the plant. Overall, steel pipes play a crucial role in providing structural integrity and efficient functionality to solar power plants.

Send your message to us

Hot sell API Seamless Pipe from CNBM International Corporation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords