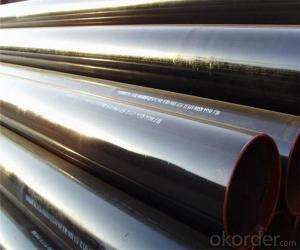

4、API Seamless Pipe from CNBM Specification:

Standard: GB, DIN, ASTM

ASTM A106-2006, ASTM A53-2007

ASME, ASTMGrade: 10#-45#, 16Mn

10#, 20#, 45#, 16Mn

20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53BThickness: 2 - 50 mm Section Shape: Round Outer Diameter: 21.3 - 620 mm Secondary Or Not: Non-secondary Application: Hydraulic Pipe Technique: Hot Rolled Certification: API Surface Treatment: factory state or painted black Special Pipe: API Pipe Alloy Or Not: Non-alloy Length 6-12M 1.Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2.Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3.Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4.Surface:black lacquered,varnish coating or galvanized.

5.Ends:Beveled or square cut,plastic capped,painted.

6.Packing:bundles wrapped with strong steel strip,seaworthy packing.

5、FAQ of API Seamless Pipe from CNBM:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !