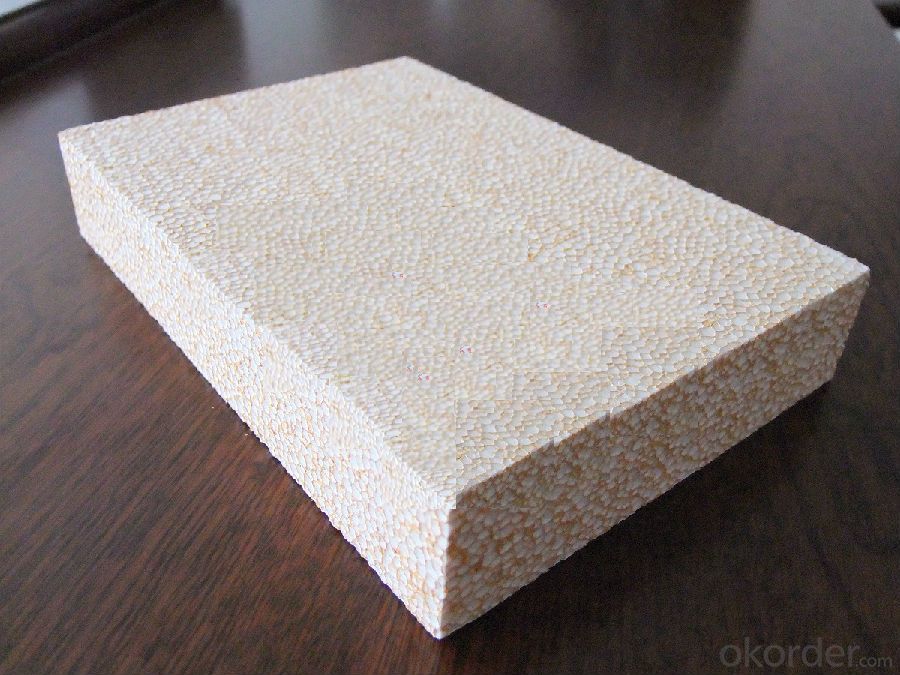

Extruded Polystyrene Board For Heat Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000

- Supply Capability:

- 60000000 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

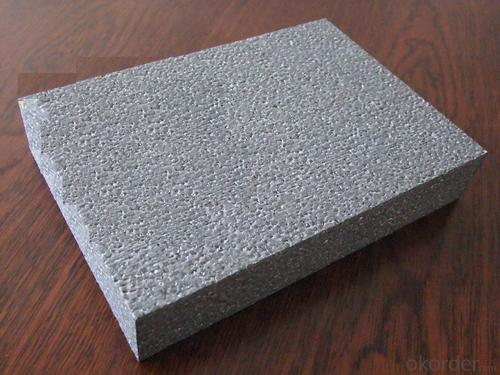

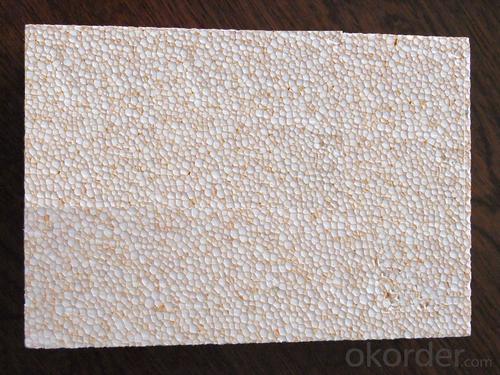

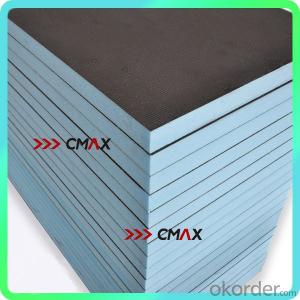

Type extruded polystyrene insulation board is a kind of rigid extruded polystyrene thermal insulation material, based on polystyrene resin as the main ingredient, adding certain proportional additive, is a kind of high performance rigid foam with honeycomb closed pore structure which manufactured through special heating extrusion forming process under the condition of strict quality control on imported production line, the interconnection wall of honeycomb structure has consistent thickness, and there will be no gap completely, therefore, the uniform organization through extrusion process makes the products have excellent thermal insulation properties, good wet moisture resistance and high pressure performance. In addition, closed-cell structure filled with CO2 gas will not cause ozone layer broken, which is more environmental friendly compared with the conventional CFC gas and HCFC gas.

Application Area: Airpot, Industries and Civil Building, Cold Storage,Highway, Railway,Hydraulic Engineering

Main Features: llent thermal insulation properties, good wet moisture resistance, high pressure performance

Advantaege:

Anchoring Nail Fixed Mounting Slot, Lap Slot

Cryogenic Secondary Foaming Improves Dimensional Stability

More Eco-friendly, More Flame-retarded Technological Level

Improve Thermal Resistance, Reduce HFC\CFC Cost

High Pressure-resistant Board, Above 900kpa

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of extruded polystyrene insulation board,is one of the large-scale professional investment mineral production bases in China. Annually more than 2000 tons. Polystyrene insulation board are exported to markets in Asian, American, Middle East, African. OEM service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within one week days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly two weeks working days can be served.

- Q: 25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- 2 fastener type steel pipe stent construction must be prepared before the construction program

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- The best bamboo pole, or plastic, aluminum alloy, then there is no child at home can have a child, then it is dangerous to fall easily hit people

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- Use the wall connection, set the location, the number of construction sites in accordance with the development of specific programs to determine. But also must meet the "construction of fastener type steel pipe scaffolding safety technical specifications JGJ130-20 lack of reminders of the United States and the United States and the United States and the United States and the United States and the United States, Note: . different erection mode, different height, the vertical spacing, horizontal spacing, each wall with a specific coverage area requirements. . pay attention to the standard is JGJ130-. do not use JGJ130-2002 old standard, the old and new standards on the wall with a little different provisions.

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- Flexible waterproof casing for Shanghai Geng high international 薨 uan arm for the seismic fortification requirements of the area, the pipeline through the walls to withstand vibration and pipe telescopic deformation, or a strict waterproof requirements of the building (building) buildings

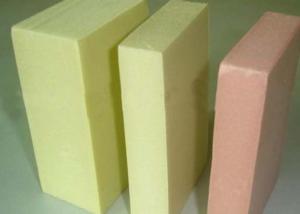

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- Market price, no quota. According to the different brands, the price is different! I hope useful to you!

- Q: Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Online under ah ~ ~! A few days ago I have a ~ ~!

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Because the middle of the lap will lead to fasteners, fasteners can not withstand such a large force, and the top can withstand

- Q: What is the difference between an extruded board and an XPS extruded board?

- 1. Civilized construction program 2. Safe construction program 3. Template construction program 4. Scaffolding construction program 5. Sambo four construction program 6. Temporary electricity construction program 7. High operating construction program 8. Tower crane construction plan 9. Multi-tower operation anti-collision construction program 10. Emergency emergency plans 11. Winter rainy season construction program 12. Significant hazard assessment measures 13. Construction organization design 14. Building energy conservation program 15. Basket construction program 16. Tower crane hoisting program

- Q: Steel structure rock wool sandwich wall panel what the amount of this set

- The key indicator of good or bad weight is the weight, that is, the weight per cubic meter. Big enough.

- Q: How to distinguish between good and bad insulation board insulation board

- Your main source of high temperature in the room is the west of the glass and the south of the window you can in the west and south from the glass 20_50 cm hanging curtains so much of the heat was blocked the roof available 60 * 60 gypsum board ceiling that Economic effect and good ceiling 15-18 yuan per square

Send your message to us

Extruded Polystyrene Board For Heat Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000

- Supply Capability:

- 60000000 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords