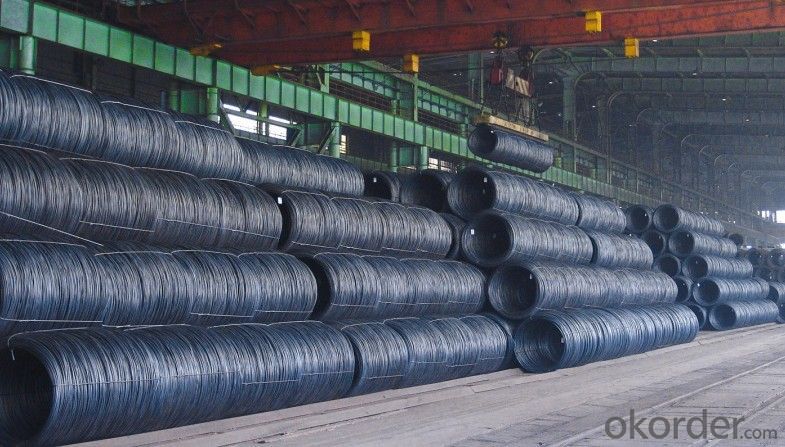

Hot Rolled Steel Wire Rod steel SAE1008 SAE1018 for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Wire Rod steel SAE1008 SAE1018 for Construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Wire Rod steel SAE1008 SAE1018 for Construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Wire Rod steel SAE1008 SAE1018 for Construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Steel Grade: Q195 Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

6.5mm can be drawing into 2mm/8.0mm can be drawing into 3mm

Type: Drawn Wire in Coil, each coil weight about 2MT

Brand Name: N-RIVER Place of Origin: Hebei, China

Chemical Composition:

Please kindly find our chemistry of our material based on Q195 as below for your information

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

| ≤ |

| ≤ | ≤ | |||

Q195 |

| 0.06-0.12 | 0.30 | 0.25 | 0.050 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q195 |

| 195 | 185 | 315-390 | 33 | 32 | |

Packaging & Delivery of Hot Rolled wire rod Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are steel rebars?

- Steel rebars, also known as reinforcement bars, are long, cylindrical steel rods that are commonly used in construction to provide strength and stability to concrete structures. These rebars are embedded within the concrete and act as a tensioning device, reinforcing the material and preventing it from cracking or collapsing under pressure. They are essential in enhancing the structural integrity and durability of buildings, bridges, and other concrete-based infrastructure projects.

- Q: How do steel rebars contribute to the overall seismic performance of a building?

- Steel rebars contribute to the overall seismic performance of a building by providing reinforcement and strength to the structure. They help resist the forces generated during an earthquake by increasing the ductility and tensile strength of the concrete. This reinforcement prevents the building from collapsing or suffering severe damage during seismic events, making it more resistant to lateral and vertical movements caused by ground shaking.

- Q: Can steel rebars be used in corrosive environments?

- Steel rebars can be used in corrosive environments, but certain precautions need to be taken to ensure their longevity and structural integrity. Corrosive environments, such as those with high levels of moisture, saltwater, or chemical exposure, can accelerate the corrosion process of steel rebars, leading to potential structural damage. To mitigate this risk, various strategies can be employed. One common approach is to use corrosion-resistant reinforcing materials, such as stainless steel rebars or epoxy-coated rebars, which provide an additional layer of protection against corrosion. These materials have proven effective in resisting corrosion even in highly corrosive environments. Another approach is to utilize corrosion inhibitors, which are chemicals added to the concrete mix or applied directly to the steel surface. These inhibitors form a protective layer around the rebars, preventing corrosive agents from reaching the steel and slowing down the corrosion process. Additionally, proper concrete cover thickness should be maintained to ensure rebars are adequately protected from exposure to corrosive elements. Adequate concrete cover acts as a barrier, preventing moisture and other corrosive agents from reaching the steel. Regular inspection and maintenance are crucial to identify any signs of corrosion early on. If corrosion is detected, appropriate measures should be taken to repair or replace the affected rebars to maintain the structural integrity of the project. In summary, while steel rebars can be used in corrosive environments, it is essential to consider the specific conditions and employ the appropriate strategies to protect against corrosion. By using corrosion-resistant materials, applying inhibitors, maintaining proper concrete cover, and conducting regular inspections, the lifespan and performance of steel rebars in corrosive environments can be significantly enhanced.

- Q: What are the factors that determine the spacing of steel rebars in a concrete structure?

- The spacing of steel rebars in a concrete structure is determined by several factors that ensure the structural integrity and strength of the concrete. These factors include: 1. Structural Design: The spacing of rebars is influenced by the structural design requirements and specifications of the concrete structure. Engineers consider the loads, stresses, and forces that the structure will experience and calculate the required reinforcement spacing accordingly. 2. Concrete Strength: The strength of the concrete being used in the structure is an essential factor in determining rebar spacing. Higher-strength concrete may require closer spacing of rebars to provide adequate reinforcement and prevent cracking or failure under load. 3. Rebar Diameter: The diameter of the steel rebars also plays a role in determining the spacing. Thicker or larger diameter rebars may require wider spacing, whereas thinner rebars typically require closer spacing to provide the desired reinforcement. 4. Bar Bending and Placing: The ease of bending and placing the rebars during construction is another important factor. The spacing is often determined by practical considerations, such as ensuring proper access for workers and equipment, and facilitating the concrete pouring process. 5. Environmental Factors: Environmental conditions, such as exposure to corrosive substances or extreme weather conditions, can influence the spacing of rebars. Closer spacing may be required in corrosive environments to provide additional protection against rust and deterioration. 6. Building Codes and Regulations: Building codes and regulations set by local authorities or relevant organizations also dictate the minimum requirements for rebar spacing in concrete structures. These codes ensure compliance with safety standards and provide guidelines for construction practices. Overall, the spacing of steel rebars in a concrete structure is a critical aspect of ensuring its strength, durability, and resilience. It is determined by a combination of structural design, concrete strength, rebar diameter, construction practicalities, environmental considerations, and adherence to building codes and regulations.

- Q: Can steel rebars be used in wastewater treatment plants?

- Yes, steel rebars can be used in wastewater treatment plants. Steel rebars are commonly used as reinforcement for concrete structures, including those found in wastewater treatment plants. The rebars provide strength and durability to the structures, ensuring they can withstand the harsh environments and corrosive nature of wastewater. However, it is important to select the appropriate grade of steel rebars that are resistant to corrosion caused by the chemicals present in wastewater.

- Q: How are steel rebars checked for proper alignment during construction?

- Steel rebars are checked for proper alignment during construction through various methods such as visual inspections, measuring tools like plumb bobs and laser levels, and using templates or guides to ensure they are placed accurately according to the structural drawings and specifications.

- Q: What are the different methods for attaching steel rebars to existing structures?

- There are several methods for attaching steel rebars to existing structures, including drilling and epoxy anchoring, mechanical anchoring using couplers, welding, and using adhesive or resin-based systems. Each method has its own advantages and considerations depending on the specific requirements and conditions of the structure.

- Q: How are steel rebars protected against chemical corrosion?

- Steel rebars are protected against chemical corrosion through a process called corrosion inhibition. This involves applying a protective coating, such as epoxy or zinc, to the surface of the rebars. Additionally, rebars can be embedded in concrete, which acts as a barrier against corrosive substances. Proper maintenance and regular inspections are essential to ensure the long-term protection of steel rebars against chemical corrosion.

- Q: How do steel rebars prevent the concrete from cracking under tension?

- Steel rebars prevent concrete from cracking under tension by providing reinforcement and increasing the tensile strength of the concrete. When the concrete undergoes tensile stress, which is the force that tends to pull it apart, the rebars distribute the stress across a larger area and absorb some of the tension. This helps to prevent the concrete from cracking by reducing the amount of stress applied to any one area and providing additional strength to withstand the forces acting upon it.

- Q: Can steel rebars be used in structures with limited construction materials?

- Steel rebars have the potential to be utilized in structures where there is a scarcity of construction materials. They are extensively employed in construction for reinforcing concrete structures, like buildings, bridges, and highways. Their role is to enhance the strength and stability of the structure, enabling it to endure heavy loads and prevent structural failure. In regions where construction materials may be limited, steel rebars can be an invaluable asset. Their durability and versatility make them suitable for various applications, rendering them a flexible choice for construction projects. Furthermore, their ease of transportation and installation make them appropriate for implementation in remote or inaccessible areas. Nonetheless, it is crucial to take into account the specific requirements and regulations of the construction project when employing steel rebars. Adequate knowledge and expertise are imperative to ensure accurate installation and adherence to safety standards. Additionally, if there are any specific limitations or restrictions on the usage of particular construction materials, it is crucial to seek advice from local authorities or professionals to determine the most suitable course of action.

Send your message to us

Hot Rolled Steel Wire Rod steel SAE1008 SAE1018 for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords