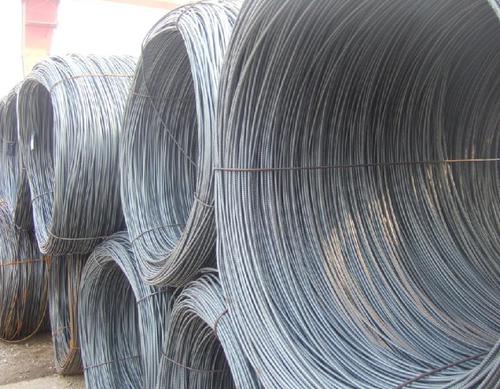

Five mm Cold Rolled Steel Rebars in Coils with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Five mm Cold Rolled Steel Rebars in Coils with High Quality:

Name | Five mm Cold Rolled Steel Rebars in Coils with High Quality | |

Diameter | 5mm, 5.5mm, 6mm, 6.5mm, 7mm, 8mm, 9mm, 10mm, 11mm, 12mm, | |

Length | 6M, 9M, 12M or as required | |

Price | Keep lower operating costs so as to offer competitive price for our clients | |

Label | to be specified by customer, generally, each bundle has1-2 labels | |

Application | Building, construction | |

Invoicing | Actual or Theoretical Weight Basis as buyer’s request. | |

2. Theoretical weight and section area of each diameter of Five mm Cold Rolled Steel Rebars in Coils with High Quality as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | ||

5 | 19.6 | 0.154 | ||

3. Packaging & Delivery of Five mm Cold Rolled Steel Rebars in Coils with High Quality:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Delivery Detail: within 45 days after received advanced payment or LC.

4. FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

5. Images of Five mm Cold Rolled Steel Rebars in Coils with High Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: What are the common defects observed in steel rebars?

- Some common defects observed in steel rebars include surface imperfections such as cracks, pits, and corrosion, as well as improper dimensions or shape, inadequate strength, and poor welding.

- Q: What is the effect of steel rebars on the seismic performance of a structure?

- Steel rebars, also referred to as reinforcing bars, play a crucial role in enhancing the seismic performance of structures by improving their overall strength and ductility. When structures are subjected to seismic forces, they undergo intense shaking and vibrations. The inclusion of steel rebars significantly enhances the strength and ductility of the structure, enabling it to withstand and absorb the energy released during an earthquake. The primary effect of steel rebars is their capacity to augment the tensile strength of concrete. Concrete is strong when compressed but weak when subjected to tension. By embedding steel rebars within the concrete, the composite material becomes capable of resisting tensile forces that may occur during an earthquake. This prevents the concrete from cracking or fracturing, ensuring the structure remains intact and functional. Furthermore, steel rebars act as a reinforcement mechanism by distributing the seismic load uniformly across the entire structure. During an earthquake, the shaking motion is dispersed throughout the building, minimizing stress concentration in specific areas. This redistribution of forces helps to maintain the overall stability of the structure, preventing localized failure and collapse. In addition, the presence of steel rebars enhances the ductility of the structure. Ductility refers to the material's ability to deform under stress without breaking. When seismic forces act on a building, the steel rebars provide flexibility and allow for controlled deformation. This plastic behavior aids in dissipating the energy generated during an earthquake, reducing the impact on the structure and minimizing potential damage. Moreover, steel rebars also contribute to the overall stiffness of the structure. By reinforcing concrete components such as columns, beams, and walls, the rigidity of the entire system is increased. This stiffness helps to limit displacement and deformation of the structure, mitigating the risk of structural failure and ensuring the safety of occupants during a seismic event. To summarize, the presence of steel rebars in a structure significantly improves its seismic performance by enhancing concrete's tensile strength, distributing seismic load, improving ductility, and increasing overall stiffness. These effects collectively enhance the structure's ability to resist and withstand the forces generated during an earthquake, ensuring the integrity of the structure and the safety of its occupants.

- Q: What is the role of steel rebars in beam and column design?

- Steel rebars play a crucial role in beam and column design as they provide reinforcement and enhance the structural integrity of these elements. In reinforced concrete structures, rebars are used to resist tensile forces that concrete alone cannot withstand. In beams, rebars are typically placed at the bottom to counteract tensile stresses caused by bending moments. By distributing the load across the beam's length, rebars effectively increase its strength and prevent cracking or failure. The rebars' ability to resist tension helps the beam maintain its shape and load-bearing capacity, ensuring the structural stability of the entire construction. Similarly, in columns, rebars are placed throughout the length to resist both axial and bending forces. They improve the column's ability to withstand compression while also providing additional resistance against lateral loads from seismic or wind forces. The presence of rebars in columns significantly enhances their load-bearing capacity and overall stability. In summary, steel rebars play a critical role in beam and column design by providing reinforcement against tensile forces, increasing structural strength, preventing cracking, and ensuring the overall stability and safety of the structure.

- Q: What are the advantages of using steel rebars over other reinforcement materials?

- There are several advantages of using steel rebars over other reinforcement materials. Firstly, steel rebars provide superior strength and durability, making them highly resistant to tensile forces, which is crucial for reinforcing structures. Additionally, steel rebars have excellent bond strength with concrete, ensuring a strong and reliable bond between the two materials. Furthermore, steel rebars are readily available and cost-effective, making them a popular choice in construction projects. Lastly, steel rebars are highly versatile, allowing for various shapes and sizes, enabling engineers to customize reinforcement according to specific project requirements.

- Q: How do steel rebars affect the overall fire resistance of concrete structures?

- The overall fire resistance of concrete structures is greatly affected by steel rebars. These reinforcement bars, also known as steel rebars, are utilized in concrete structures to provide strength and stability. Their behavior when exposed to fire can either improve or weaken the fire resistance of the concrete structure. The fire resistance of the structure benefits from the inclusion of steel rebars. Steel's high thermal conductivity aids in dissipating the heat produced during a fire, preventing localized overheating and reducing the risk of structural failure. This dispersal of heat through the steel rebars slows down the rate at which the concrete's temperature rises, allowing for more time to evacuate and fight the fire. Furthermore, the presence of steel rebars also helps maintain the structural integrity of the concrete during a fire. Concrete has low tensile strength, and when subjected to high temperatures, it tends to crack and spall. However, the presence of steel rebars mitigates this issue by acting as reinforcement, holding the concrete together and preventing it from disintegrating due to heat. However, it is important to note that steel rebars can have a negative impact on fire resistance if not designed or protected properly. Insufficient size and spacing of the rebars can lead to a rapid transfer of heat through the concrete, resulting in premature failure. Additionally, if the rebars are not adequately protected with fire-resistant materials, they can lose their strength and integrity, further compromising the overall fire resistance of the structure. To ensure optimal fire resistance, designers and engineers consider various factors such as the size, spacing, and coating of the steel rebars, as well as the thickness of the concrete cover. Additionally, fireproofing measures such as using intumescent coatings, fire-resistant insulation, and fireproof claddings can be implemented to enhance the fire resistance of steel rebars and the overall concrete structure. In conclusion, steel rebars play a vital role in the fire resistance of concrete structures. When appropriately designed and protected, they enhance fire resistance by dissipating heat and maintaining structural integrity. However, inadequate design or lack of protection can compromise fire resistance. Therefore, it is crucial to adhere to proper design guidelines and implement appropriate fireproofing measures to ensure the overall fire safety of concrete structures.

- Q: What are the different methods of protecting steel rebars from fire?

- There are several methods available for protecting steel rebars from fire. One common approach is to use fire-resistant coatings or paints that can be applied directly to the rebars. These coatings create a barrier that helps to prevent the steel from reaching its critical temperature during a fire. Another method is to encase the rebars in a fire-resistant material, such as concrete, which acts as a protective layer. Additionally, fireproofing sprays or intumescent coatings can be used to provide insulation and slow down the transfer of heat to the rebars. Finally, ensuring proper spacing and cover of rebars within the concrete structure can also offer some level of fire protection.

- Q: What is the resistance of steel rebars against acid attacks?

- Steel rebars have a high resistance against acid attacks due to their inherent corrosion-resistant properties. The steel's protective oxide layer helps prevent the acid from penetrating and causing significant damage to the rebars. However, prolonged exposure to highly concentrated or aggressive acids may eventually lead to corrosion, necessitating appropriate protective measures.

- Q: Can steel rebars be used in underwater structures?

- Yes, steel rebars can be used in underwater structures. Steel rebars are commonly used in construction projects to reinforce concrete structures and provide additional strength and stability. When it comes to underwater structures, such as bridges, dams, and offshore platforms, the use of steel rebars is crucial due to their excellent strength and durability. However, the use of steel rebars in underwater structures requires additional considerations. One of the main concerns is corrosion, as exposure to water and salt can accelerate the corrosion process. To mitigate this issue, corrosion-resistant steel rebars, such as stainless steel or epoxy-coated rebars, are used. These rebars have protective layers that prevent direct contact between the steel and water, minimizing the risk of corrosion. Furthermore, proper design and construction techniques are essential when using steel rebars in underwater structures. Adequate concrete cover and proper spacing between rebars are crucial to ensure sufficient protection against corrosion and maintain the structural integrity of the underwater structure. Additionally, regular inspection and maintenance are necessary to identify and address any signs of corrosion or deterioration in the rebars. In conclusion, steel rebars can be used in underwater structures, but it requires careful consideration of corrosion protection measures and adherence to proper design and construction practices. With the right precautions in place, steel rebars can provide the necessary strength and durability for underwater structures.

- Q: What are the different methods of reinforcing concrete structures using steel rebars?

- There are several methods of reinforcing concrete structures using steel rebars. 1. Traditional Reinforcement: This method involves placing steel rebars in the formwork before pouring concrete. The rebars are positioned in a predetermined pattern and secured with wire or tie rods to ensure they stay in place during the concrete placement. This method is commonly used for reinforcing columns, beams, and slabs. 2. Pre-stressed Reinforcement: In this method, high-strength steel rebars are pre-stressed before being placed in the concrete structure. This is usually achieved by stretching the rebars and then anchoring them to resist the tensile forces that will be exerted on the structure. Pre-stressed reinforcement is commonly used in bridges and large-span structures where high strength and durability are required. 3. Post-tensioning: Post-tensioning is a technique used to reinforce concrete structures after the concrete has hardened. It involves inserting steel tendons into pre-determined ducts or sleeves within the concrete and then applying tension to the tendons using hydraulic jacks. This process helps to counteract the tensile forces and increase the overall strength and load-carrying capacity of the structure. 4. Fiber Reinforcement: Instead of using traditional steel rebars, fiber reinforcement involves adding small fibers made of materials like glass, polypropylene, or steel to the concrete mix. These fibers help to distribute and control cracks that may occur due to shrinkage or thermal expansion. Fiber reinforcement is often used in applications such as industrial flooring, shotcrete, and precast concrete products. 5. Reinforced Concrete Masonry: In this method, steel rebars are inserted into the mortar joints of concrete masonry units (CMUs) to increase the strength and stability of the structure. The rebars are placed vertically and horizontally at specific intervals and then grouted to ensure a solid bond between the rebars and the CMUs. Overall, these different methods of reinforcing concrete structures using steel rebars provide various options for engineers and designers to enhance the strength, durability, and load-carrying capacity of concrete structures, depending on the specific requirements of the project.

- Q: How do steel rebars contribute to the overall sustainability of a structure?

- Steel rebars contribute to the overall sustainability of a structure by increasing its durability, strength, and longevity. By reinforcing concrete, rebars help prevent cracks and structural failures, reducing the need for costly repairs or replacements. This contributes to the long-term sustainability of a structure as it minimizes waste and resource consumption. Additionally, steel rebars can be recycled at the end of a structure's life, reducing the environmental impact and promoting a circular economy.

Send your message to us

Five mm Cold Rolled Steel Rebars in Coils with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords