Hot Rolled Steel Plate SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

GRADE:

SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD:

GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC:

1) Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2) Thickness:1.5mm-200mm or as customers’ special requirements

3) Length: 2-12m or as customers’ special requirements

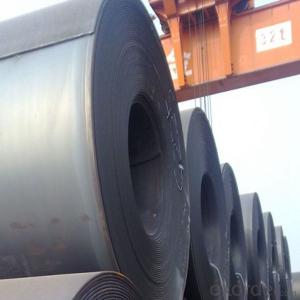

DETAILED PICTURES FOR STEEL COILS

PACKAGING &DELIVERY FOR STEEL COILS/SHEETS

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: Are steel sheets suitable for water tanks?

- Yes, steel sheets are suitable for water tanks. Steel is a strong and durable material that can withstand the weight of water and provide long-lasting protection against corrosion. Additionally, steel tanks can be easily customized and are often used for storing large volumes of water in various industries and applications.

- Q: What are the different quality standards for steel sheets?

- Steel sheets must meet specific requirements and be suitable for their intended use, which is why there are several quality standards in place. Some of the most common standards for steel sheets are as follows: 1. Carbon structural steel sheets used for general structural purposes are regulated by ASTM A36/A36M. This standard outlines the material's chemical composition, mechanical properties, and other relevant factors. 2. ASTM A568/A568M covers the general requirements for steel sheet products, including hot-rolled, cold-rolled, and coated sheets. It provides specifications for dimensions, tolerances, and surface quality. 3. EN 10130 specifies the requirements for cold-rolled low carbon steel flat products, including steel sheets, in Europe. It outlines the material's chemical composition, mechanical properties, and other relevant factors. 4. JIS G 3302 is a Japanese industrial standard that covers the requirements for hot-dip zinc-coated steel sheets and coils. It includes specifications for the coating weight, surface finish, and mechanical properties. 5. ISO 3574 is an international standard that specifies the requirements for cold-reduced carbon steel sheet of commercial and drawing qualities. It provides guidelines for dimensions, tolerances, and mechanical properties. 6. GB/T 2518 is a Chinese national standard that outlines the requirements for continuous hot-dip zinc-coated steel sheets and coils. It includes specifications for the coating weight, surface finish, and mechanical properties. These quality standards ensure that steel sheets have consistent properties and characteristics, making them suitable for various applications such as construction, automotive, manufacturing, and more. Manufacturers, suppliers, and end-users must adhere to these standards to guarantee the quality and reliability of steel sheet products.

- Q: What are the different sheet metal forming techniques for steel sheets?

- Steel sheets can be shaped into desired forms and structures using various techniques for sheet metal forming. Below are some common techniques used for steel sheets: 1. Bending: To create angles, curves, or complex shapes, the sheet is bent either manually or with the help of machines like press brakes. 2. Stretch forming: This technique involves stretching and forming the sheet over a mold or die, especially for large and curved components. 3. Deep drawing: By using a punch and a die, the sheet metal is formed into desired shapes, often used for cylindrical or box-like structures such as cans, pots, or automotive components. 4. Roll forming: The sheet metal is passed through a series of rollers to gradually shape it into the desired form. This technique is commonly used for producing long and continuous shapes like rails, tubes, or channels. 5. Spinning: A spinning tool is used to rotate the sheet metal against a mandrel, shaping it into cylindrical or conical shapes such as lampshades or cookware. 6. Embossing: This technique involves stamping a pattern or design onto the sheet metal to create a raised or recessed surface. It is commonly used for decorative purposes or to enhance the structural integrity of the sheet. 7. Hydroforming: Hydraulic pressure is utilized to shape the sheet metal into complex forms, often employed in the creation of automotive components like car body panels or exhaust systems. These examples illustrate the wide range of sheet metal forming techniques available for steel sheets. The choice of technique depends on the desired shape, complexity, and specific requirements of the application.

- Q: Are steel sheets susceptible to warping or bowing?

- Yes, steel sheets are susceptible to warping or bowing under certain conditions such as exposure to high temperatures, uneven cooling, or excessive loads.

- Q: Are the steel sheets suitable for electrical applications?

- Yes, steel sheets are suitable for electrical applications. Steel is a good conductor of electricity, which makes it an ideal material for various electrical components and applications. It can be used for electrical enclosures, panels, cabinets, and other infrastructure where electrical equipment is housed. Steel sheets are also commonly used for grounding systems, electrical connectors, and electrical appliances. Additionally, steel sheets can provide durability and protection against environmental factors, such as corrosion or fire, which are important considerations in electrical applications.

- Q: Can steel sheets be used for artistic or sculptural projects?

- Yes, steel sheets can be used for artistic or sculptural projects. Steel is a versatile material that offers a wide range of creative possibilities. Its strength and durability make it suitable for both indoor and outdoor artworks. Steel sheets can be cut, welded, shaped, and manipulated to create intricate designs, sculptures, and installations. Artists and sculptors often choose steel sheets for their ability to hold intricate details and withstand various weather conditions. Additionally, steel sheets can be painted, polished, or treated to achieve different textures and finishes, further enhancing the artistic appeal of the final piece. Overall, steel sheets provide artists with a robust and versatile medium to express their creativity and bring their artistic visions to life.

- Q: What is the typical lead time for steel sheet orders?

- The typical lead time for steel sheet orders can vary depending on various factors such as the quantity and size of the order, the availability of the specific steel sheet, and the location of the supplier. In general, lead times for steel sheet orders can range from a few days to several weeks. For smaller orders or readily available steel sheets, the lead time is often shorter, typically around a week or less. This is because suppliers usually have these items in stock and ready to be shipped upon receiving an order. On the other hand, larger or custom orders may require additional production time and can have longer lead times. This is because the supplier may need to manufacture the steel sheets according to the specific requirements of the order, which can take several weeks depending on the complexity and volume. It is important to note that lead times can also be influenced by external factors such as market demand, transportation delays, or unforeseen circumstances. Therefore, it is recommended to communicate with the supplier directly to get an accurate estimate of the lead time for a specific steel sheet order.

- Q: How do steel sheets compare to wood sheets?

- Steel sheets and wood sheets have distinct differences in terms of strength, durability, and use cases. Firstly, steel sheets are known for their exceptional strength and durability. They can withstand heavy loads, extreme weather conditions, and are highly resistant to warping, rotting, and insect damage. Wood sheets, on the other hand, are less robust and can be vulnerable to moisture, termites, and decay if not properly treated or maintained. In terms of versatility, steel sheets offer a wide range of applications. They are commonly used in construction, automotive, and manufacturing industries due to their high tensile strength and structural stability. Wood sheets, on the other hand, are often used in interior design, furniture making, and smaller-scale construction projects due to their natural aesthetic appeal and ease of manipulation. Additionally, steel sheets are fire-resistant, making them a safer option compared to wood sheets, which are combustible and can contribute to the spread of fire. Steel sheets also have a longer lifespan, requiring less maintenance and replacement compared to wood sheets, which may need regular refinishing, sealing, or replacement due to wear and tear. However, wood sheets have their advantages as well. They are typically more cost-effective than steel sheets, making them a popular choice for budget-conscious projects. Wood sheets also have better insulation properties, providing natural warmth and soundproofing qualities. Ultimately, the choice between steel sheets and wood sheets depends on the specific requirements of the project, including factors such as budget, desired aesthetics, structural needs, and environmental considerations.

- Q: Can steel sheets be used in construction projects?

- Yes, steel sheets can be commonly used in construction projects. They are versatile, durable, and provide strength and stability to structures. Steel sheets are often used for roofing, flooring, walls, and various structural components in buildings.

- Q: What are the different types of steel sheets available?

- There are several different types of steel sheets available, including cold rolled steel sheets, hot rolled steel sheets, galvanized steel sheets, stainless steel sheets, and alloy steel sheets.

Send your message to us

Hot Rolled Steel Plate SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords