Hot Rolled Steel Deformed Steel Bar Debar / Rebar KS BS HRB400 HRB500

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Deformed Steel Bar (Debar / Rebar)KS BS HRB400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Deformed Steel Bar (Debar / Rebar)KS BS HRB400 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Deformed Steel Bar (Debar / Rebar)KS BS HRB400 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Commodity: Mild Steel Flat Bar

Standard: GB;JIS

Material: Q195-235;SS400

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition of Q235

Standard | GB | HRB400 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Place of origin | Hebei, China mainland | ||

Advantages | exact size, regular package, chemical and mechanical properties are stable. | ||

Type | Hot rolled deformed steel bar | ||

Brand name | DRAGON | ||

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m bar(kg) |

6 | 28.27 | 0.222 | 2.664 |

8 | 50.27 | 0.395 | 4.74 |

10 | 78.54 | 0.617 | 7.404 |

12 | 113.1 | 0.888 | 10.656 |

14 | 153.9 | 1.21 | 14.52 |

16 | 201.1 | 1.58 | 18.96 |

18 | 254.5 | 2.00 | 24 |

20 | 314.2 | 2.47 | 29.64 |

22 | 380.1 | 2.98 | 35.76 |

25 | 490.9 | 3.85 | 46.2 |

28 | 615.8 | 4.83 | 57.96 |

32 | 804.2 | 6.31 | 75.72 |

36 | 1018 | 7.99 | 98.88 |

40 | 1257 | 9.87 | 118.44 |

50 | 1964 | 15.42 | 185.04 |

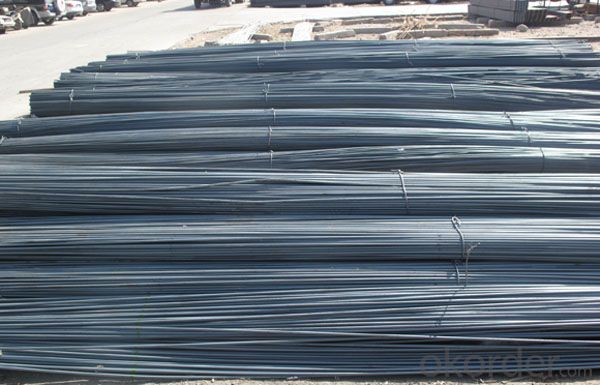

Packaging & Delivery of Hot Rolled Hot Rolled Steel Deformed Steel Bar (Debar / Rebar)KS BS HRB400

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do steel rebars resist corrosion?

- Steel rebars resist corrosion due to the presence of a protective oxide layer that forms on their surface when exposed to oxygen and moisture. This oxide layer acts as a barrier, preventing further contact between the steel and corrosive agents, thus extending the rebars' lifespan and durability.

- Q: What are the main uses of threaded steel?

- The rebar is a kind of small section steel, mainly used for the skeleton of reinforced concrete construction members. Steel is usually used for reinforced concrete, its role is to increase the friction fringe, the rebar and concrete secant integrally formed together, tic phenomenon can not occur in the role of external force, improve the strength of concrete.

- Q: What is the role of steel rebars in industrial flooring construction?

- Steel rebars play a crucial role in industrial flooring construction as they provide reinforcement and strength to the concrete. By being embedded within the concrete slab, rebars help to distribute loads evenly, resist tension forces, and prevent cracking or structural failure. They enhance the durability and longevity of the flooring, making it capable of withstanding heavy loads, impact, and vibrations commonly encountered in industrial settings.

- Q: What are the common methods of cutting steel rebars on construction sites?

- There are several common methods used to cut steel rebars on construction sites. These methods are chosen based on the specific requirements of the project and the available equipment. One commonly used method is using a rebar cutter, which is a handheld tool specifically designed for cutting steel rebars. These cutters are operated manually and can easily cut through rebars of varying diameters. They are convenient to use on-site due to their portability and ease of operation. Another method is using a chop saw, also known as a cut-off saw or an abrasive saw. This method involves using a high-speed abrasive disc to make precise cuts on the steel rebars. Chop saws are commonly used when there is a need for accurate and clean cuts, especially when multiple rebars need to be cut to the same length. Oxy-fuel cutting is another method that can be used for cutting steel rebars. This method involves using a torch that combines oxygen and a fuel gas, typically acetylene, to create a high-temperature flame. The intense heat generated by the torch can effectively cut through steel rebars of varying thicknesses. Oxy-fuel cutting is often used when there is a need for rapid cutting or when dealing with thicker rebars. Plasma cutting is also a popular method for cutting steel rebars. This technique uses a high-velocity jet of ionized gas, known as plasma, to melt and remove the metal. Plasma cutting is suitable for cutting rebars of different thicknesses and can achieve precise and clean cuts. It is often used when working with rebars that have intricate shapes or when there is a need for fast and accurate cutting. It is important to note that safety precautions should always be followed when cutting steel rebars on construction sites. This includes wearing appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection. Additionally, proper training and supervision are crucial to ensure the correct use of cutting equipment and to minimize the risk of accidents or injuries.

- Q: Can steel rebars be used in structures with high thermal insulation requirements?

- Steel rebars can be used in structures with high thermal insulation requirements, but additional measures need to be taken to minimize thermal bridging. Steel is a good conductor of heat, so if rebars are not properly insulated, they can create thermal bridges that compromise the insulation of the structure. However, there are several strategies to address this issue. One approach is to use rebars with a lower thermal conductivity, such as stainless steel rebars, which have better insulation properties compared to regular steel rebars. Another option is to thermally break the rebars by using insulation materials or coatings around them to prevent the transfer of heat. Moreover, careful detailing and design can also help reduce thermal bridging. Ensuring that rebars are properly embedded within the insulation layer and avoiding direct contact between the rebars and the exterior or interior surfaces of the structure can help minimize heat transfer. Overall, while steel rebars can be used in structures with high thermal insulation requirements, it is crucial to implement appropriate measures to address thermal bridging and maintain the desired level of insulation.

- Q: How are steel rebars connected or spliced together?

- Steel rebars are typically connected or spliced together using various methods, including lap splicing, mechanical splicing, and welded splicing. Lap splicing involves overlapping the rebars and tying them together using wire or steel ties. Mechanical splicing involves using couplers or connectors to join the rebars together, providing a strong and efficient connection. Welded splicing involves welding the rebars together, creating a permanent and robust connection. The choice of splicing method depends on factors such as project requirements, structural design, and construction techniques.

- Q: Can steel rebars be bent or shaped?

- Steel rebars have the capability to be bent or shaped. In construction, rebars are frequently employed to enhance concrete structures, and it is customary to bend or shape them in order to meet the project's specific design criteria. Multiple tools and techniques, including manual bending, mechanical bending machines, and hydraulic presses, can be utilized to accomplish the bending or shaping of rebars. The flexibility of steel rebars in terms of bending or shaping facilitates the creation of intricate and tailor-made reinforcement patterns, guaranteeing the concrete structure's ability to withstand the intended loads and stresses.

- Q: What is the standard size of a steel rebar?

- The standard size of a steel rebar typically ranges from 6mm to 50mm in diameter.

- Q: How do steel rebars affect the overall construction cost of commercial buildings?

- Steel rebars can significantly affect the overall construction cost of commercial buildings. Firstly, steel rebars are an essential component in reinforcing the concrete structure of the building, enhancing its strength and durability. However, the cost of steel rebars can be quite high, especially when constructing large-scale commercial buildings that require a substantial amount of reinforcement. This cost includes the purchase, transportation, and installation of steel rebars, all of which contribute to the overall construction expenses. Therefore, the quantity and quality of steel rebars used directly impact the total construction cost of commercial buildings.

- Q: Can steel rebars be used in power plant construction?

- Power plant construction can indeed utilize steel rebars. These rebars, also referred to as reinforcing bars, are frequently employed in the construction sector to provide concrete structures with strength and support. In power plant construction, it is common practice to reinforce concrete foundations, walls, and structural components like columns and beams with steel rebars. The remarkable tensile strength and durability of these rebars make them highly suitable for enduring the heavy loads and extreme conditions typically encountered in power plant environments. Additionally, steel rebars can enhance the overall strength and stability of power plant infrastructure by being employed in the construction of reinforcing cages for underground pipelines and cooling towers.

Send your message to us

Hot Rolled Steel Deformed Steel Bar Debar / Rebar KS BS HRB400 HRB500

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords