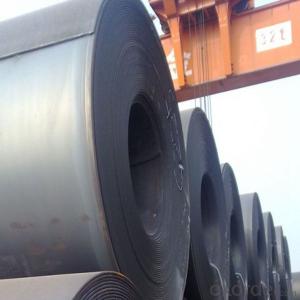

Hot Rolled Steel Coil Shipping Thick Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Description

Because of poor working conditions, hull shell to chemical corrosion and electrochemical corrosion of sea water and sea creatures, microbial corrosion;Hull bear larger impact waves and alternating load;Ship shape the processing method of complex factors, so strict in hull structure steel.First good toughness is one of the most critical requirements, in addition, require high strength, good corrosion resistance, weldability, processing forming performance and surface quality.For assuring quality and ensure there is enough toughness and requirements of the chemical composition of the Mn/C above 2.5, also has strict requirements for carbon equivalent, and recognized by the survey department of steel production.Hull with structural steel in accordance with the minimum yield point strength level is divided into: general strength structural steel and high strength structural steel.General strength and high strength steel with hull structural steel points two kinds, general strength steel according to quality points A, B, D and E four grades;Strength of high strength steel and two levels and three quality grades;AH32, DH32, EH32, AH36, DH36, EH36.

2. Main Features

With the Marine equipment was placed on the strategic emerging industries, to shipping industry put forward the urgent request form upgrade.Offshore platform of 50% percentage points higher than the ship class, USES the steel plate must have high strength, high toughness, fatigue resistance, lamellar tearing resistance, good weldability and corrosion resistance to sea water, etc.Built from the current several platform, a platform with a volume of about 20000 tons of steel, of which about 90% domestic steel products, import proportion about 10%;Steel varieties used for AH - EH planking, of which 10 mm, 8 mm, 6 mm thickness of several specifications Gao Jiangban accounted for more than 80%, according to the level points, E board will account for 70% of the total amount of steel - 80%;Width of 2.4 meters of specifications of the dosage of steel plate is more, less dosage of steel plate width of 3 meters above specifications.

3. Excellent Product Image

4. Application

Our hot-rolled steel coil and sheet are applied to a wide range of uses such as automobile, electrical appliance, machinery manufacturing, container manufacturing, shipbuilding, bridge, pipeline, and receive high acclaim from our customers for its excellent quality.

5. FAQ

1.Q: Do you have attended any exhibition?

A: We almost go to Canton Fair and Overseas Exhibitions every year.

2. Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. Q: How long can we receive the product after purchase?

A: Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

Why choose us?

Pre-sale Service

1. Sample can be offered with sample charge and courier fee by buyer's side.

2. We have full stock,and can deliver within short time.Many styles for your choices.

3. OEM and ODM order are accepted, Any kind of logo printing or design are available.

4. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you

5. All of our products are produce by our professional workman and we have our high-work-effect foreign trust-worthy sales team.

6. We have 18 years' experience of design, manufacture and sell lingerie, we cherish every order from our honor.

After you choose

1. Count the most efficient shipping cost and make invoice to you at once.

2. Check quality again, then send out to you at 1-2 working day after your payment.

3. Email you the tracking no, and help to chase the parcels until it arrive you.

- Q: What is the maximum thickness of steel coils?

- The maximum thickness of steel coils can vary depending on the specific application and manufacturing process. However, in general, steel coils can have a maximum thickness ranging from a few millimeters to several centimeters. The thickness is typically determined by factors such as the intended use of the steel coils, the type of steel being used, and the capabilities of the manufacturing equipment.

- Q: How do the sandpaper grits compare with different coarse levels of steel wool? For example, I'm finishing a homemade entertainment center, and using a tinted polyurethane, and it says to use 000 grade steel wool, but mine is #3, could I use some sanpaper instead, and what grit?

- 150 grit is standard for final sanding for poly. You could use 220 if you finish with something thinner like lacquer of if that's all you have. Even finer would work but not do much sanding.

- Q: What are the common certifications required for steel coils?

- The common certifications required for steel coils depend on the specific industry and application of the coils. However, there are several widely recognized certifications that are commonly required. 1. ISO 9001: This certification ensures that the manufacturer has implemented a quality management system that meets international standards. It verifies that the manufacturer has the necessary processes and controls in place to consistently produce high-quality steel coils. 2. ISO 14001: This certification focuses on environmental management systems. It ensures that the manufacturer is committed to minimizing its environmental impact and reducing waste in the production process. 3. ISO 45001: This certification pertains to occupational health and safety management systems. It ensures that the manufacturer has implemented measures to protect the health and safety of its employees and stakeholders. 4. ASTM International Standards: The American Society for Testing and Materials (ASTM) has established various standards for steel coils. These standards cover aspects such as chemical composition, mechanical properties, and dimensional tolerances. Compliance with these standards ensures that the coils meet the specified requirements and are suitable for their intended use. 5. EN Standards: The European Committee for Standardization (CEN) has developed a set of standards for steel coils, known as EN standards. These standards cover similar aspects as ASTM standards but are specific to the European market. 6. JIS Standards: The Japanese Industrial Standards (JIS) are widely used in the steel industry in Japan and other countries in Asia. Compliance with JIS standards ensures that the coils meet the specific requirements of the Japanese market. 7. Product-specific certifications: Depending on the application of the steel coils, additional certifications may be required. For example, if the coils are intended for automotive use, certifications such as ISO/TS 16949 (Quality Management Systems for the Automotive Industry) may be necessary. It is important to note that the specific certifications required may vary depending on the region, industry, and customer requirements. Manufacturers should consult with their customers and industry standards organizations to determine the exact certifications necessary for their steel coils.

- Q: What are the different grades of steel used in coil manufacturing?

- There are several grades of steel used in coil manufacturing, including low carbon steel, high carbon steel, stainless steel, and alloy steel. Each grade has its own unique properties and is chosen based on the specific requirements of the application, such as strength, corrosion resistance, or heat resistance.

- Q: Cast steel welding

- Normal okorder /.. Mild steel and cast steel produces a very long stream of brilliant sparks, with some forking. CI produces much shorter, dull reddish sparks and the volume of sparks is much less. many highly branched or intermittent sparks will be seen.

- Q: (I'm not sure if steel is in fact a mineral)But I want to know if .. Last say topaz is stronger/harder then steel

- Sandpaper , quartz will wear a hole in alloy steel. Just rub it. The steel that is.

- Q: How are steel coils used in the manufacturing of construction reinforcement bars?

- Steel coils are used in the manufacturing of construction reinforcement bars by being processed through a series of steps. The coils are first uncoiled and then straightened before being cut to the desired length. These cut lengths are then shaped and bent into the required reinforcement bar shape using specialized machinery. Finally, the bars are heat-treated and cooled to enhance their strength and durability. Overall, steel coils serve as the primary raw material for the production of construction reinforcement bars, providing the necessary strength and structural integrity to concrete structures.

- Q: Which of the two are better for exhaust manifolds, im guessing the stainless steel right?

- stainless

- Q: So carbon is gas that brakes down to hydrogen and helium before going in...And steel can go a little farther towards sun before evaporating.. 200 degrees closer at leastso steel is full of a heavier gas bomb in my hypothesis and needs to be broken up outside stars(broken down)Is steel capable of going into sun with an element thats wrong wayLike iron has no air to boil outAnd steel goes just as far with carbon in it..Other words can u answer me with..Carbon is already IN the sun and is capable of braking down Carbon INSIDE the star/sunOnly way I see steel boiling is inside and it releases carbon gas at once..carbon bomb

- Carbon NEVER breaksdown into hydrogen and helium. Steel is an alloy of iron that contains carbon. Send either into the sun and they go from being a solid to a liquid to a gas to a plasma as the temperature increases on its approach but neither breaksdown into something else. Carbon as a solid or a plasma is still carbon and the same is true for iron. There are small amounts of most elements in the sun but it is mostly hydrogen.

- Q: In terms of weight to strength titanium is stronger. But is it stronger than mild steel? If it is stronger, how much stronger is it?

- Yes ,i think so. The two most useful properties of the metal form are corrosion resistance, and the highest strength-to-weight ratio of any metal.[4] In its unalloyed condition, titanium is as strong as some steels, but 45% lighter.[5] There are two allotropic forms[6] and five naturally occurring isotopes of this element; 46Ti through 50Ti, with 48Ti being the most abundant (73.8%).[7] Titanium's properties are chemically and physically similar to zirconium.

Send your message to us

Hot Rolled Steel Coil Shipping Thick Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords