hot rolled steel coil/sheet -SAE1006 in Good Quality from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

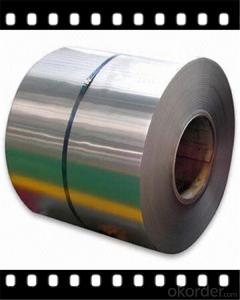

Hot-Rolled Steel Sheets and Coils are applied to a wide range of uses such as automobile, electrical appliance, machinery manufacturing, container manufacturing, shipbuilding, bridge, pipeline, and receive high acclaim from our customers for its excellent quality.

Specification:

Product: | Hot Rolled Steel Coils/Sheets |

Material: | Q195,Q235,A36,SS400,S235JR,Q345,ST37-2, CCSB etc |

Standard : | JIS G3002 GB/T251B |

Technique: | hot rolled |

Thickness | 1.2mm to 200mm |

Tolerance of thickness: | :+/-0.03mm |

Width: | 750mm-2000mm |

Tolerance of width: | :+/-5.00mm (aiming to +/-2.00mm) |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm, 1250mm,1500mm |

Length: | According to requirement |

Coil ID: | 508mm-610mm |

Coil Weight: | 10-25 Metric Tons |

Surface: | Black, Chromate, fingerprint resistant treatment, slight oiled or non-oiled, dry |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

Delivery Time | Within 30 days after received 30% deposit or workable L/C |

Payment Terms: | L/C,T/T |

Iamge:

Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

- Q: What are the common coil transportation methods?

- The common coil transportation methods include trucking, railway transportation, and shipping.

- Q: How do steel coils contribute to the construction sector?

- Steel coils play a crucial role in the construction sector in various ways. Firstly, steel coils are extensively used in the manufacturing of structural components such as beams, columns, and trusses. These components form the backbone of buildings and provide the necessary strength and stability to the structure. Steel coils are processed and shaped into these structural components, ensuring that they can withstand the heavy loads and forces experienced in construction. Additionally, steel coils are utilized in the production of reinforcement bars, commonly known as rebars. These rebars are embedded within concrete structures, enhancing their tensile strength and preventing cracks or fractures. This reinforcement is essential in constructing durable and resilient infrastructure, from bridges and highways to buildings and stadiums. Moreover, steel coils find applications in the fabrication of roofing and cladding materials. The coils are processed and formed into corrugated sheets or panels, which are then used to cover roofs and walls. These steel roofing and cladding materials offer excellent protection against environmental factors such as rain, wind, and UV radiation. Furthermore, they provide thermal insulation, fire resistance, and aesthetic appeal to the constructed buildings. Furthermore, steel coils contribute to the construction sector through their use in the production of various mechanical components, including pipes, tubes, and fittings. These components are essential for plumbing, heating, ventilation, and air conditioning systems in buildings. Steel's durability, corrosion resistance, and ability to handle high-pressure conditions make it an ideal material for these applications. The versatility, strength, and durability of steel coils make them indispensable in the construction sector. They provide the necessary materials for constructing robust structures, reinforcing concrete, and producing essential components. Steel coils not only contribute to the safety and longevity of buildings but also play a vital role in the overall development and growth of the construction industry.

- Q: i am debating weather to get the hercules rmx or the steel and from what i have read, the only differences between them is the rmx has a sound card (built in interface-to connect to the computer, correct me if im wrong) and that the steel has more effects. however, i cannot find out which effects it has so it would be a big help if someone can answer this for me.thanx

- I guess that since Steel doesn’t have headphones connection and a built-in soundcard, one won’t be able to play a track on one deck and prelisten the track on the other without using an external usb soundcard, right? I was wondering what’s the point in releasing a product like this if you also have to buy a bunch of equipment to be able to do sth “fondamental”: play while preparing your next song. However since the steel is meant for DJ’s who already have a great soundcard, but I don’t see why a Steel+sound card is ONLY for pro’s. Yes it’s designed for pro’s but you can use it as a beginner. Some consoles you also need to consider: Hercules Steel/RMX, Numark OMNI/Steath. It's all personal decision. Peace, Love Happiness

- Q: I have a carbon steel file that I want to bend in a letter C shape. So, what is the malliable temperature? If it's low, could it be done in a camp fire?

- It's now not rather that rough. You can use your charcoal grill to do it. First construct a colossal fireplace in it after which bury the metal within the coals. It'll simplest take approximately ten minuites or so for the metal to warmth by way of. Then decide on it out of the coals with tongs and drop it right into a bucket of water. Repeat as preferred. Eventually it is going to get as brittle as glass. To repair this, you have got to anneal the steel. Again warmth the steel within the coals, simplest this time allow it keep there till the coals cross the entire manner out all by way of themselves. Next day while the entire manner cool, Take it out and blank it off. Viola!, you may have hardened metal.

- Q: What are the dimensions of steel coils used in the power generation industry?

- The specific application and requirements determine the varying dimensions of steel coils used in the power generation industry. Generally, there is a wide range of sizes and thicknesses available for power generation steel coils. For power generation purposes, the width of steel coils can range from a few inches to several feet, depending on the intended equipment or machinery. These coils are specifically designed to fit manufacturing processes or components within power generation systems. The thickness of steel coils used in power generation can vary greatly. Thicker coils are commonly used for heavy-duty applications that require increased strength and durability. On the other hand, thinner coils may be suitable for less demanding tasks or when reducing weight is a priority. Furthermore, the weight of steel coils for power generation can vary based on their dimensions and the specific steel material used. Consideration of weight is crucial during transportation, installation, and handling of the coils. It is worth noting that manufacturers in the power generation industry can customize the dimensions of steel coils to meet specific project requirements. They work closely with power generation companies to understand their needs and offer tailored solutions that meet their dimensional specifications.

- Q: How are steel coils inspected for weldability using welding tests?

- Steel coils can be inspected for weldability using a variety of welding tests. One common method is the bend test, where a section of the coil is cut and bent to evaluate the quality of the weld. This test helps determine if the weld is brittle or contains any defects that could compromise its integrity. Additionally, the guided bend test is performed to assess the ability of the weld to withstand bending without cracking or breaking. Another technique used is the macro etch test, where a sample is prepared by cutting a cross-section of the coil and then etching it with a chemical solution. This test helps reveal any imperfections or inconsistencies in the weld, such as porosity, slag inclusions, or lack of fusion. Furthermore, the hardness test is conducted to measure the hardness of the weld. This is important as excessive hardness can lead to cracking or brittleness, while insufficient hardness may result in weld failure under certain conditions. Additionally, non-destructive testing methods like ultrasonic testing, magnetic particle inspection, or radiographic examination can also be employed to detect any internal defects, such as cracks or voids, in the steel coil welds without damaging the material. These welding tests are crucial in ensuring the quality and weldability of steel coils before they are used in various applications. By conducting thorough inspections, any potential issues can be identified and addressed, ensuring that the steel coils meet the required standards for weldability and structural integrity.

- Q: Two different shaving razors I'm looking to buy have different specs. in terms of the metals used for the blade; one being 1045 surgical stainless steel, the other 440 stainless (not sure if its A B or C, but probably 440A or 440B because it's not specified). So which one is better for the intended use as a shaving razor?

- Type 440 combines such a high grade of cutlery steel, toughness and economy that it is actually known as razor blade steel. Browsing around (a lot) more, it seems that 1045 Surgical Steel is popular in straight razors used by barbers. These razors are honed by stropping with leather and last practically forever. From the above, I would guess that it might be easier to lose the edge on 1045, but also easier to re-sharpen it, that it won't easily knick because probably not so hard as 440. I'm not sure if it would be more expensive, unless it has a superior handle etc. So, I would expect to spend a little more effort over the lifetime of the 1045, maybe pay a little more for it, but have a longer lifetime. hth.

- Q: How do steel coils impact the overall cost of production?

- The overall cost of production in various industries is greatly affected by steel coils. Initially, the expense of the steel coils themselves can be quite significant. The price of steel is influenced by several factors, including supply and demand, raw material costs, and market fluctuations. Any increase in the price of steel coils can directly impact the overall cost of production, as they are a major component in the manufacturing process. Furthermore, the operational costs of production are also influenced by steel coils. These coils are commonly used in different manufacturing processes, such as stamping, rolling, and forming, which require specialized machinery. The efficiency and effectiveness of these processes greatly depend on the durability, quality, and size of the steel coils. If the coils are of low quality or not suitable for the specific production requirements, it can result in increased downtime, machinery maintenance, and rework, all contributing to higher production costs. Additionally, the transportation costs associated with steel coils can impact the overall cost of production. Steel coils are typically heavy and bulky, requiring special handling and transportation arrangements. The logistics costs can be significantly influenced by factors such as the distance between the supplier and the production facility, as well as the chosen mode of transportation. Any rise in transportation expenses, such as fuel prices or shipping fees, can directly affect the overall cost of production. Lastly, the availability of steel coils can also impact production costs. During periods of high demand or limited supply, the price of steel coils may increase, resulting in higher production costs. Moreover, if there is a shortage of steel coils due to trade restrictions or disruptions in the supply chain, manufacturers may have to resort to alternative materials or sources, which could be more expensive or of lower quality. These factors can have a ripple effect on the overall cost of production. In conclusion, steel coils have a significant impact on the overall cost of production. Their cost, quality, transportation, and availability all influence the efficiency, effectiveness, and affordability of the manufacturing process. Therefore, manufacturers must carefully consider and manage these factors to optimize their production costs and maintain competitiveness in their respective industries.

- Q: every time i look for steel over the internet like to build cars motorcycles ect i only get steel pipes where can i get steel sheets

- This okorder /... Most towns have a steel supply house/ business, check your yellow pages. Also check with local welding and machine shops. They can give you ideas and or their suppliers. They often have bits and pieces that you might buy, instead of ordering a full sheet of material. Wingman

- Q: 1943 steel pennies

- if you collect coins, you need to learn that they must never be cleaned. cleaning, while it might make them look pretty, ruins their value as a collectable. ask your coin dealer.

Send your message to us

hot rolled steel coil/sheet -SAE1006 in Good Quality from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords