Hot Rolled Stainless Steel Coils/Sheets From China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

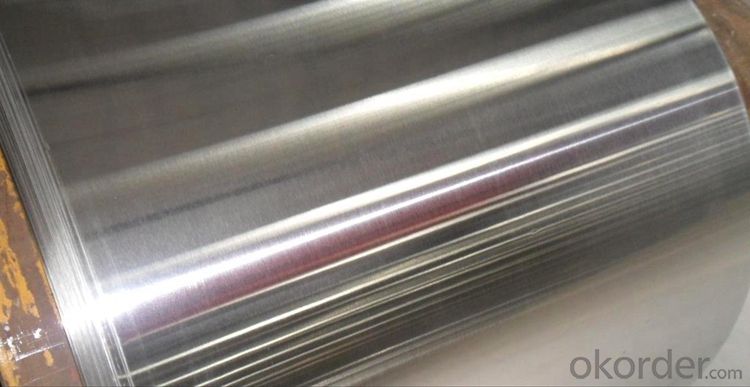

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: What are the different types of stainless steel sheet edges?

- Stainless steel sheets come in three main types of edges: mill edge, slit edge, and deburred edge. 1. The mill edge is the most common type and is produced during manufacturing. It has a rough, unfinished edge that is typically straight and perpendicular to the sheet's surface. It is suitable for applications where a smooth edge is not necessary. 2. Slit edge sheets are created by cutting large rolls of stainless steel into narrower widths. These edges are smoother and more precise compared to the mill edge. They are commonly used in applications that require a polished and precise edge, such as architectural finishes or fabrication processes. 3. A deburred edge is achieved by removing any sharp or rough edges from the stainless steel sheet. This is done to improve safety during handling or installation. Deburring can be done through grinding, sanding, or using specialized tools. The resulting edge is smooth and free from burrs or sharp protrusions. It's important to consider the specific application and requirements when choosing the edge type for a stainless steel sheet. Each type has its own advantages and limitations, and factors like aesthetics, functionality, and safety should be taken into account when selecting the appropriate edge for a project.

- Q: Can stainless steel sheets be used for elevator mirrors?

- Certainly! Elevator mirrors can indeed be made using stainless steel sheets. Stainless steel, being both durable and versatile, is a favored material for elevator interiors due to its sleek and polished look. By polishing stainless steel sheets to a mirror-like finish, they can be effectively utilized as reflective surfaces for elevator mirrors. Furthermore, stainless steel's resistance to corrosion makes it well-suited for the humid and frequently challenging conditions typically encountered in elevators.

- Q: Are stainless steel sheets suitable for food processing?

- Indeed, stainless steel sheets prove to be an excellent choice for food processing purposes. The food and beverage industry extensively utilizes stainless steel owing to its exceptional properties and hygienic characteristics. Notably, it does not react with food, is highly resistant to corrosion, and does not introduce any taste or smell to the processed food. Moreover, stainless steel is effortless to clean and upkeep, rendering it an optimal selection for food processing machinery, worktops, and various other surfaces. Additionally, it withstands elevated temperatures and effectively resists bacterial proliferation, thereby establishing itself as a reliable and secure material for food processing activities.

- Q: Are stainless steel sheets suitable for decorative applications?

- Yes, stainless steel sheets are suitable for decorative applications. Stainless steel is a versatile material that offers both durability and aesthetic appeal, making it ideal for various decorative purposes. It is commonly used in interior design, architecture, and furniture manufacturing due to its sleek and modern look. Stainless steel sheets can be shaped, cut, and fabricated into different patterns, textures, and finishes, allowing for endless design possibilities. Whether it is for wall cladding, backsplashes, countertops, or decorative accents, stainless steel sheets can enhance the visual appeal of any space. Additionally, stainless steel is resistant to corrosion, staining, and heat, ensuring its long-lasting beauty even in challenging environments.

- Q: Can stainless steel sheets be used for countertops?

- Yes, stainless steel sheets can be used for countertops. Stainless steel is a durable and versatile material that is resistant to stains, heat, and bacteria, making it an excellent choice for kitchen countertops. It is easy to clean, maintain, and has a sleek and modern appearance. Stainless steel countertops are commonly used in commercial kitchens but are also becoming increasingly popular in residential settings due to their durability and hygienic properties.

- Q: Are stainless steel sheets suitable for medical implants?

- Yes, stainless steel sheets are suitable for medical implants. Stainless steel is a common material used in medical implants due to its desirable properties such as corrosion resistance, strength, and biocompatibility. These sheets can be fabricated into a variety of shapes and sizes, making them versatile for different types of implants. Additionally, stainless steel has been extensively studied and proven to be safe for long-term implantation in the human body. It is also cost-effective compared to other implant materials. However, it is important to note that the specific grade of stainless steel and the surface finish are critical factors in determining the suitability for medical implants. The grade of stainless steel must meet the requirements for biocompatibility and corrosion resistance, while the surface finish should be smooth to minimize the risk of infection and promote proper tissue integration. Overall, stainless steel sheets are a reliable and widely used material for medical implants.

- Q: What's the difference between stainless steel 304 and stainless steel 202?

- 304 stainless steel is a common stainless steel material, the density of 7.93 g/cm3, the industry is also called 18/8 stainless steel. High temperature resistance of 800 degrees, with good processability, high toughness characteristics, widely used in industry and furniture decoration industry and food and medical industry. The common marking methods in the field are 0Cr18Ni9, SUS304.

- Q: What are the advantages of using stainless steel sheets in the medical industry?

- Using stainless steel sheets in the medical industry offers several benefits: 1. Maintaining Hygiene and Cleanliness: Stainless steel's non-porous nature makes it easy to clean and disinfect, making it an excellent option for medical equipment, surgical instruments, and hospital furniture. It resists bacteria, mold, and other pathogens, ensuring a hygienic environment. 2. Ensuring Longevity and Durability: Stainless steel can withstand harsh conditions, including high temperatures, humidity, and corrosive substances. This durability extends the lifespan of medical equipment and instruments, reducing the need for frequent replacements. 3. Providing Strength and Safety: Stainless steel sheets offer exceptional strength and structural integrity, making them suitable for applications that require resistance to impact and pressure. This is crucial in the medical industry, where instruments and equipment are constantly utilized and handled. 4. Resisting Stains and Corrosion: Stainless steel is highly resistant to stains and corrosion, even in aggressive environments. This property is essential in medical facilities where exposure to various chemicals and liquids is common. The resistance to corrosion ensures that stainless steel sheets remain intact and do not release harmful substances into the environment. 5. Enhancing Aesthetic Appeal: Stainless steel sheets have a sleek and modern appearance that contributes to the overall aesthetic appeal of medical equipment and instruments. This creates a positive impression on patients, instilling confidence in the quality and cleanliness of the medical facility. 6. Promoting Recyclability: Stainless steel is a sustainable material that can be recycled without any loss in quality. This reduces the environmental impact of the medical industry by minimizing waste and conserving resources. In conclusion, stainless steel sheets offer advantages such as hygiene, durability, strength, resistance to stains and corrosion, aesthetic appeal, and recyclability. These qualities make stainless steel a reliable and cost-effective choice for medical equipment, instruments, and other applications in healthcare settings.

- Q: What is the function of a stainless steel plate at the top of the steel chimney?

- At present, the commonly used classification methods are classified according to the characteristics of the steel structure, the chemical composition of steel and the combination of the two. Generally divided into martensitic stainless steel, ferritic stainless steel, austenitic stainless steel, duplex stainless steel and precipitation hardening stainless steel, etc., or divided into chromium, stainless steel and nickel stainless steel two categories.

- Q: Are stainless steel sheets environmentally friendly?

- There are multiple reasons why stainless steel sheets are considered environmentally friendly. Firstly, stainless steel is an incredibly durable and long-lasting material. Unlike plastic or wood, stainless steel sheets have a lifespan of several decades and do not easily deteriorate. This means that they do not need frequent replacement, resulting in reduced waste production. Moreover, stainless steel is entirely recyclable. When it reaches the end of its life cycle, stainless steel can be melted down and used to create new products without losing any of its original properties. This significantly decreases the demand for raw materials and reduces the energy required for manufacturing new items. Additionally, stainless steel sheets are non-toxic and do not release harmful chemicals into the environment. Unlike certain plastics or treated woods, stainless steel does not emit VOCs or other pollutants that can contribute to air or water pollution. Furthermore, stainless steel is corrosion-resistant, requiring minimal maintenance and eliminating the need for chemicals or coatings to protect it from rust or degradation. This reduces dependence on environmentally harmful substances and minimizes the release of pollutants into the environment. In conclusion, stainless steel sheets are environmentally friendly due to their durability, recyclability, non-toxic nature, and resistance to corrosion. These characteristics make stainless steel a sustainable and responsible choice for various applications, ranging from construction to household appliances.

Send your message to us

Hot Rolled Stainless Steel Coils/Sheets From China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords