Hot Rolled Stainless Steel Coil 304 Narrow Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

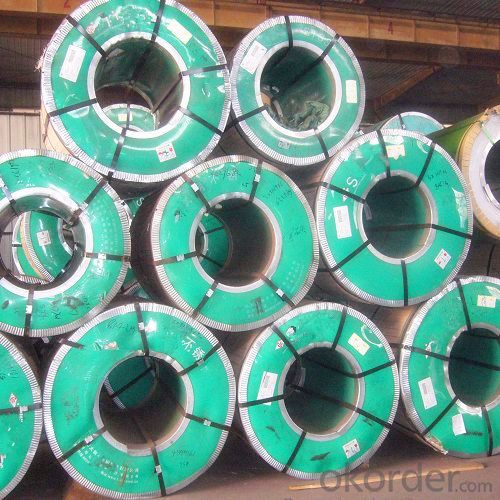

Hot Rolled Stainless Steel Coil 304 Narrow Strip

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.my company long-term

supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Specifications

1.surface:NO.1

2.standard:JIS, AISI, GB

3.width: 0.55m, 0.65m, 1.0m, 1.22m, 1.5m, 2.0m or requirement

ASTM 304

(%):C=0.07, Mn=2.00, P=0.045, S=0.030, Si=0.075, Cr=17.5-19.5, Ni=8.0-10.5, N=0.10

Physical Properties

Tensile strength σb (MPa) ≥ 520

the conditions yield strength σ0.2 (MPa) ≥ 205,

elongation δ5 (%) ≥ 40

Reduction of ψ (%) ≥ 50,

hardness: ≤ 187

HB; ≤ 90

HRB; ≤ 200H

Type | Hot Rolled Stainless Steel Coil 304 Narrow Strip |

Thickness | 2.5mm-4.0mm |

Width | 510mm, 550mm, 650mm |

Length | according to weight |

Brand name | CNBM |

Standard | ASTM, AISI, DIN, GB, JIS etc |

Material | 304 |

Application | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | Within 15 days since getting the deposit or LC origin |

Surface | NO.1 |

Productivity | 5000 tons/month |

- Q: Can stainless steel strips be bent or formed?

- Indeed, it is possible to bend or form stainless steel strips. Stainless steel possesses exceptional malleability, allowing for effortless shaping and bending into diverse configurations. This attribute has contributed to its widespread adoption across multiple sectors, encompassing construction, automotive, and manufacturing. To shape or bend stainless steel strips, a variety of techniques can be employed, including cold bending, roll forming, and press braking. The choice of method hinges upon the desired form and the thickness of the stainless steel strip. Nevertheless, it is crucial to acknowledge that achieving precise and optimal outcomes in the bending or forming process necessitates specialized equipment and expertise.

- Q: What are the different types of corrosion that can affect stainless steel strips?

- There are several types of corrosion that can affect stainless steel strips. 1. General corrosion: This is a uniform attack on the surface of the stainless steel strip, resulting in a loss of material over a large area. It occurs when the protective oxide layer on the stainless steel is damaged or compromised, usually due to exposure to aggressive chemicals or high temperatures. 2. Pitting corrosion: Pitting corrosion is localized corrosion that leads to the formation of small pits or holes on the stainless steel surface. It occurs when certain aggressive chemicals or environments penetrate the protective oxide layer, causing localized breakdown and corrosion. 3. Crevice corrosion: Crevice corrosion occurs in narrow gaps or crevices on the stainless steel strip, such as gaps between overlapping materials or under gaskets. These crevices provide a stagnant environment where aggressive chemicals can accumulate, leading to localized corrosion. 4. Stress corrosion cracking (SCC): SCC is a type of corrosion that occurs under tensile stress in the presence of a corrosive environment. It can lead to sudden failure of the stainless steel strip, even at stress levels well below its yield strength. SCC is often associated with exposure to certain chemicals or environments, such as chlorides or sulfides. 5. Intergranular corrosion: Intergranular corrosion affects the grain boundaries of the stainless steel strip, causing localized corrosion along these boundaries. It occurs when the stainless steel is exposed to certain conditions, such as high temperatures or welding, which can cause sensitization and subsequent corrosion along the grain boundaries. 6. Galvanic corrosion: Galvanic corrosion occurs when stainless steel comes into electrical contact with a dissimilar metal in the presence of an electrolyte, such as water or saltwater. The electrical potential difference between the two metals leads to accelerated corrosion of the less noble metal (stainless steel in this case). It is important to consider these different types of corrosion when selecting the appropriate stainless steel grade and implementing proper corrosion prevention measures to ensure the longevity and performance of stainless steel strips.

- Q: What are the factors affecting the thermal conductivity of 111 stainless steel strips?

- The factors affecting the thermal conductivity of 111 stainless steel strips include the composition and microstructure of the steel, the presence of alloying elements, the grain size and orientation, the temperature, and the presence of impurities or defects in the material.

- Q: Can stainless steel strips be formed into different shapes?

- Yes, stainless steel strips can be formed into different shapes through various metalworking processes such as bending, rolling, and stamping.

- Q: Are stainless steel strips resistant to heat?

- Stainless steel strips exhibit exceptional heat resistance, rendering them highly suitable for applications involving elevated temperatures. They possess the ability to endure temperatures as high as 1200°C (2200°F) while retaining both their strength and structural integrity. This impressive heat resistance can be attributed to the significant chromium content found in stainless steel, which generates a protective oxide layer on the surface. This layer effectively shields against oxidation and ensures the maintenance of mechanical properties, even under extreme heat conditions. Consequently, stainless steel strips find extensive utilization in critical sectors such as automotive, aerospace, food processing, and construction, where heat resistance stands as an indispensable requirement.

- Q: What industries commonly use stainless steel strips?

- Stainless steel strips are commonly used in various industries such as automotive, aerospace, construction, food processing, pharmaceutical, and manufacturing.

- Q: Can stainless steel strips be used in the aerospace engine components?

- Aerospace engine components can indeed utilize stainless steel strips. Stainless steel is renowned for its impressive strength, durability, and ability to withstand corrosion, making it ideal for various applications in the aerospace sector. When it comes to engine components, specifically turbine blades, stainless steel strips are employed for their exceptional heat resistance and mechanical properties. These strips are capable of enduring high temperatures and pressures, ensuring reliable performance even in extreme conditions. Furthermore, they offer excellent fatigue resistance, which is vital for components that regularly experience stress and strain cycles within the engine. In conclusion, the incorporation of stainless steel strips in aerospace engine components can enhance the efficiency, safety, and lifespan of aircraft engines.

- Q: What are the common uses of stainless steel strips in the aerospace fastener industry?

- Due to their exceptional properties, stainless steel strips find widespread use in the aerospace fastener industry. Fasteners, such as bolts, screws, and rivets, are commonly manufactured using stainless steel strips, fulfilling a crucial role in securing aircraft components and ensuring the aircraft's structural integrity and safety. The aerospace industry favors stainless steel strips for several reasons. These strips possess a high strength-to-weight ratio, corrosion resistance, and the ability to withstand extreme temperatures. Consequently, they are well-suited for fasteners exposed to challenging environments like high altitudes, extreme temperatures, and corrosive substances. Stainless steel strips also serve as essential materials for spring clips and retaining rings in the aerospace fastener industry. These components are vital for securing different parts of an aircraft, including panels, wires, and hoses. The flexibility and durability of stainless steel strips make them ideal for these applications, as they can endure repeated stress while retaining their shape and strength over time. Additionally, stainless steel strips play a role in producing shims and spacers in the aerospace fastener industry. Shims, thin strips inserted between surfaces to fill gaps or ensure precise alignment, and spacers, used to maintain specific component distances, benefit from the excellent dimensional stability and resistance to deformation offered by stainless steel strips. These qualities are crucial for applications where precision and reliability are paramount. To summarize, stainless steel strips have extensive applications in the aerospace fastener industry. Their high strength, corrosion resistance, ability to withstand extreme temperatures, and dimensional stability make them indispensable in manufacturing fasteners, spring clips, retaining rings, shims, and spacers. These components play a vital role in maintaining the structural integrity and safety of aircraft, establishing stainless steel strips as a crucial material in the aerospace industry.

- Q: What is the maximum width available for stainless steel strips?

- The maximum width available for stainless steel strips can vary depending on the specific manufacturer and supplier. However, in general, stainless steel strips are commonly available in widths ranging from 0.5 inches to 24 inches. Additionally, some manufacturers may offer wider strips up to 48 inches or more, depending on the specific requirements and capabilities of their production facilities. It is important to check with individual suppliers to determine their specific maximum width capabilities for stainless steel strips.

- Q: Can stainless steel strips be used in harsh weather conditions?

- Yes, stainless steel strips can be used in harsh weather conditions. Stainless steel is known for its excellent corrosion resistance, making it highly resistant to rust and other forms of degradation caused by exposure to moisture, humidity, and extreme temperatures. This makes stainless steel strips a reliable and durable choice for applications that are exposed to harsh weather conditions, such as outdoor structures, building facades, roofing, and marine environments. Stainless steel's resistance to corrosion is due to the presence of chromium in its composition, which forms a protective layer on the surface of the metal, preventing it from reacting with the surrounding environment. Additionally, stainless steel is also resistant to UV radiation and can withstand high winds, making it suitable for use in areas prone to storms and hurricanes. Overall, stainless steel strips are an excellent option for applications that require strength, durability, and resistance to harsh weather conditions.

Send your message to us

Hot Rolled Stainless Steel Coil 304 Narrow Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords