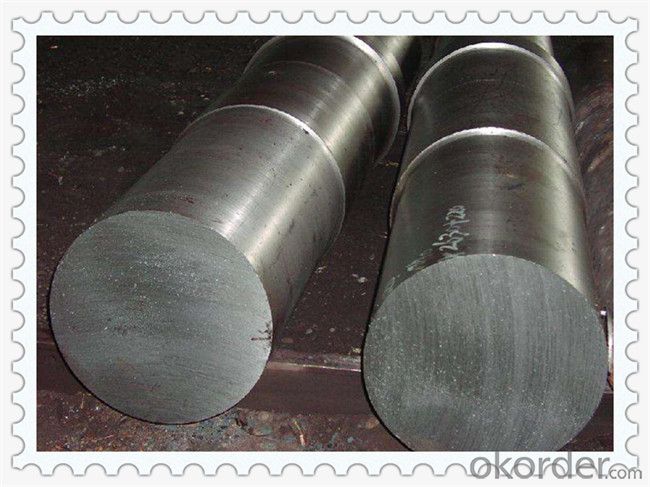

Q235 Hot Rolled Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

SS490 hot rolled carbon steel round bar

Dimensions: 15-300mm

Near the seaport, low cost, quick delivery

SGS BV inspection, Good reputation &service

Product name | SS490 hot rolled carbon steel round bar |

Dimensions | 15-300mm |

Length | 4-12m |

Standard | ASTM,BS,GB,JIS |

Other Grade | Q215,Q235,HPB300,SS330-SS490,A36,SAE1015-1020,S235JR,S275JR,ST37-2,etc |

Brand | RGTS |

Application | Mild Steel Round Bar is used for making security grills, screens, Construction and Machine Manufacture. |

Finish condition | hot rolled |

Appearance | new |

Sales mode | factory direct sales |

Quality assurance | mill test certificate is provided, third party inspection is acceptable |

Trade term | FOB/CIF/CFR |

Payment term | 30%T/T in advance, balance against B/L copy;Sight irrevocable LC |

Delivery time | Within 15-30 days after receiving original LC or deposit, also according to the quantity |

Loading port | Xingang tianjin, China |

Certification | ISO9001:2000/BV |

SS490 hot rolled carbon steel round bar details

Size Tolerance: +/-5mm

Length tolerance: +100mm/-0mm

Side length tolerance: +/-2mm

Straightness:Max 6mm/m

Both end of each bar must be cut

Ladle furnaced and vacuum de-gassed

Show heat No. on each bar

SS490 hot rolled carbon steel round bar

Chemical Composition:

P% ≤0.050

S% ≤0.050

Cr% ≤0.20

Physical Property (MPa):

Y/S: ≥285

T/S: 490~610

- Q: Can steel round bars be used in the production of sporting goods?

- Sporting goods can indeed utilize steel round bars. Steel, a versatile material renowned for its strength and durability, proves fitting for a wide spectrum of applications within the sporting goods industry. To illustrate, steel round bars can be employed to fabricate various components, including shafts, handles, frames, and supports for sporting equipment such as golf clubs, hockey sticks, weightlifting bars, and exercise machines. The robust tensile strength of steel ensures that these components can withstand the rigorous forces and pressures exerted during sports activities, thus affording stability and longevity to the resultant products. Additionally, steel round bars can be effortlessly machined, welded, and molded into different shapes and sizes to meet the particular requirements of each sporting good. Furthermore, steel's ability to resist corrosion renders it an ideal choice for outdoor sporting equipment that is subjected to diverse weather conditions. In summary, steel round bars are an immensely popular option in the production of sporting goods owing to their strength, durability, versatility, and capacity to endure the demands of various sports.

- Q: What is the difference between a forged and a peeled steel round bar?

- A forged steel round bar and a peeled steel round bar are both types of steel bars used in various industries for different applications. However, there are distinct differences between the two in terms of their manufacturing processes and physical characteristics. A forged steel round bar is made by heating a solid steel billet to a high temperature and then applying pressure to shape it into the desired form. This process involves the use of machinery, such as hammers or presses, to shape the steel and create the round bar. The forging process imparts strength and durability to the steel, making it suitable for applications that require high strength and resistance to wear and tear. On the other hand, a peeled steel round bar is produced through a different manufacturing process known as peeling or turning. In this process, a solid steel bar is rotated against a cutting tool, which removes the outer layer of the bar, resulting in a smooth and precise surface finish. Peeling removes any surface defects or imperfections present in the original bar, improving its dimensional accuracy and surface quality. In terms of physical characteristics, forged steel round bars typically have a rougher surface texture due to the nature of the forging process. This rough texture can provide enhanced grip or adhesion when used in certain applications. Additionally, forged bars often have a denser and more uniform internal grain structure, which contributes to their superior mechanical properties. Peeled steel round bars, on the other hand, possess a smooth and shiny surface finish as a result of the peeling process. This smooth surface makes peeled bars suitable for applications that require aesthetic appeal or require a low coefficient of friction. However, the peeling process may result in a slight reduction in the overall diameter of the bar. In summary, the main difference between a forged and a peeled steel round bar lies in their manufacturing processes and resulting physical characteristics. Forged bars are created through the application of pressure, resulting in a rougher surface texture and superior mechanical properties. Peeled bars, on the other hand, are produced by removing the outer layer of a steel bar, resulting in a smooth surface finish and improved dimensional accuracy. The choice between these two types of bars ultimately depends on the specific requirements of the application at hand.

- Q: Can steel round bars be used in the manufacturing of appliances?

- Yes, steel round bars can be used in the manufacturing of appliances. Steel is a durable and versatile material that can be shaped into different forms, including round bars, which can be used for various purposes in appliance manufacturing such as structural support, handles, or components.

- Q: How do you calculate the length of a steel round bar?

- To calculate the length of a steel round bar, you need to measure its diameter and then use a simple formula involving the diameter and the mathematical constant pi (π). First, use a caliper or a measuring tape to measure the diameter of the steel round bar at its widest point. Make sure to measure across the center of the bar for an accurate result. Once you have the diameter, you can calculate the circumference of the round bar by multiplying the diameter by pi (π). The formula to calculate the circumference is: Circumference = π × Diameter Finally, to determine the length of the round bar, you either need to know the number of complete rotations it makes or measure the distance covered by it. If you know the number of rotations, multiply the circumference by the number of rotations. If you are measuring the distance covered, simply use the measured distance as the length of the round bar.

- Q: Are steel round bars suitable for the production of springs?

- Indeed, springs can be produced using steel round bars. Steel, renowned for its exceptional strength and durability, finds widespread application in spring manufacturing. The circular configuration of these bars facilitates effortless shaping and molding, rendering them an ideal choice for spring production procedures. Steel round bars can be conveniently machined and heat-treated to impart the desired spring attributes, including elasticity and resilience. Furthermore, steel boasts a remarkable tensile strength, enabling it to endure substantial loads. Consequently, it proves well-suited for applications necessitating robust and dependable springs.

- Q: Are steel round bars used in the construction industry?

- Yes, steel round bars are commonly used in the construction industry. They are often used as structural elements, such as reinforcement in concrete structures, as well as in the fabrication of various components and fittings.

- Q: Can steel round bars be used for making handrails?

- Yes, steel round bars can be used for making handrails. Steel round bars are commonly used in construction and fabrication due to their strength and durability. They can be easily shaped and welded to create handrails that provide support and safety for staircases, balconies, and other elevated areas. Additionally, steel round bars can be finished with various coatings or treatments to enhance their corrosion resistance and aesthetics. Overall, steel round bars are a popular choice for making handrails due to their strength, versatility, and ability to withstand heavy usage.

- Q: Are steel round bars resistant to fire?

- Steel round bars are highly resistant to fire. Steel is known for its excellent fire resistance properties due to its high melting point and low thermal conductivity. In the event of a fire, steel round bars will not easily ignite or burn. Additionally, steel's structural integrity remains intact even at high temperatures, making it a preferable choice for construction materials in fire-prone areas. This resistance to fire makes steel round bars a reliable and safe option for various applications, including building structures, industrial equipment, and fire-resistant barriers.

- Q: Can steel round bars be used for making automotive chassis?

- Yes, steel round bars can be used for making automotive chassis. Steel round bars offer excellent strength, durability, and load-bearing capabilities, making them suitable for withstanding the weight and stress of an automotive chassis. Additionally, steel's flexibility and malleability allow for customization and shaping to meet specific design requirements.

- Q: How do you calculate the weight of a steel round bar based on its length and diameter?

- To calculate the weight of a steel round bar based on its length and diameter, you can use the following equation: Weight = (π/4) x (Diameter^2) x Length x Density Here, π represents the mathematical constant pi (approximately 3.14159), Diameter is the measurement of the steel round bar across its widest point, Length is the overall length of the bar, and Density is the density of steel, which is typically around 7850 kilograms per cubic meter. To calculate the weight, first square the diameter, then multiply it by the length and density. Finally, multiply the result by π/4 to obtain the weight of the steel round bar in the desired units (typically kilograms or pounds). It's important to note that this equation assumes the steel round bar is a solid cylinder with a uniform diameter. If the bar has any variations or irregularities, the weight calculated using this equation may not be entirely accurate.

Send your message to us

Q235 Hot Rolled Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords