Automotive Grade Hot Rolled Aluminum Coil 5005H14 - Aluminum Coil Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Hot Rolled Aluminium Coil 5005H14 for Automotive

Name | Aluminum Coil |

Brand | CNBM |

Alloy | 1100H-18, 3003-H24,3003-H26,3005-H26,8011,3004,3105,5005,etc. |

Thickness | 0.1~1.5mm |

Width | <2000mm< span=""> |

MOQ | 1 MT |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 1MT - 2MT |

2. Application of Hot Rolled Aluminium Coil 5005H14 for Automotive

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Hot Rolled Aluminium Coil 5005H14 for Automotive

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

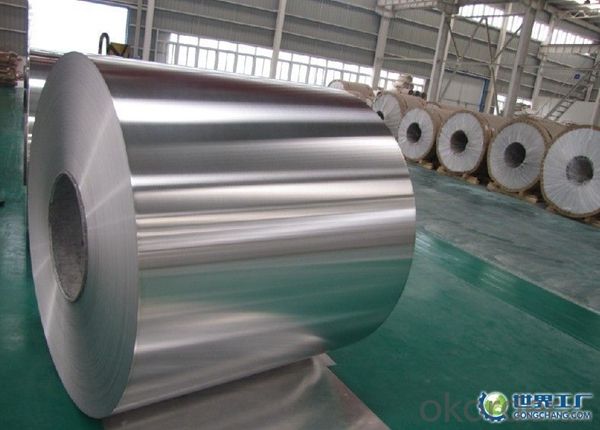

5. Image of Hot Rolled Aluminium Coil 5005H14 for Automotive

6. Package and shipping of Hot Rolled Aluminium Coil 5005H14 for Automotive

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the maximum temperature resistance of aluminum coils?

- The maximum temperature resistance of aluminum coils depends on various factors, such as the alloy composition, purity, and the specific application. However, in general, aluminum has a relatively low melting point of around 660 degrees Celsius (1220 degrees Fahrenheit). Consequently, the maximum temperature resistance of aluminum coils typically ranges between 200 and 400 degrees Celsius (392 to 752 degrees Fahrenheit). Beyond these temperatures, aluminum may start to undergo structural changes, such as softening or deformation, which can impact its performance and integrity. Therefore, it is important to consider the specific requirements and limitations of the application when determining the maximum temperature resistance of aluminum coils.

- Q: Is it possible to create baskets or containers using aluminum coils?

- <p>Yes, aluminum coils can be used to make baskets or containers. Aluminum is a lightweight, durable, and malleable material that can be easily shaped and bent into various forms. It is commonly used in manufacturing due to its strength and resistance to corrosion. For baskets or containers, aluminum coils can be woven or molded into the desired shape, offering both functionality and aesthetic appeal. However, it's important to consider the thickness and gauge of the aluminum to ensure the structure's stability and durability for its intended use.</p>

- Q: How do aluminum coils compare to nickel coils in terms of conductivity?

- Compared to nickel coils, aluminum coils typically exhibit lower electrical conductivity. This is mainly attributable to the fact that aluminum has a higher resistivity than nickel. Concerning conductivity, nickel emerges as a superior electrical conductor owing to its lower resistivity. Consequently, nickel coils are frequently favored in situations where high conductivity is vital, like in electrical circuits or heating elements. Nonetheless, it is crucial to acknowledge that aluminum coils still possess reasonable conductivity and may prove suitable for specific applications where cost-effectiveness or lightweight properties outweigh other considerations.

- Q: Are aluminum coils available in different colors?

- Yes, aluminum coils are available in different colors.

- Q: What are the pros and cons of utilizing aluminum coils in storage applications?

- <p>Aluminum coils offer several advantages for storage, including high durability, corrosion resistance, and lightweight properties which make them easy to handle. They are also recyclable and have good thermal conductivity, which can be beneficial in temperature-controlled environments. However, there are downsides such as higher initial costs compared to some other materials and potential for denting or damage if not properly handled. Additionally, while aluminum is generally non-magnetic, it can be attracted to strong magnets, which might be a consideration in certain storage scenarios.</p>

- Q: Is it possible to utilize aluminum coils in the automotive industry?

- <p>Yes, aluminum coils are widely used in the automotive industry. They are employed in various applications such as engine parts, heat exchangers, and body panels due to their lightweight, corrosion resistance, and high strength-to-weight ratio. Aluminum's recyclability and energy efficiency in production also contribute to its popularity in vehicle manufacturing.</p>

- Q: What is the thickness tolerance of aluminum coils?

- The thickness tolerance of aluminum coils varies depending on the grade and manufacturing process. Typically, aluminum coils have a standard thickness tolerance of approximately +/- 0.005 inches (+/- 0.13 mm). However, it is important to note that this tolerance can be further adjusted or refined based on the specific requirements of the customer and the capabilities of the manufacturer. Certain specialized aluminum coil manufacturers may offer even tighter thickness tolerances, usually around +/- 0.002 inches (+/- 0.05 mm), to cater to more precise or demanding applications. To ensure the desired thickness tolerance is met for a specific project or application, it is always recommended to consult with the manufacturer or supplier.

- Q: Are aluminum coils suitable for decorative purposes?

- Aluminum coils are indeed appropriate for decorative purposes. Aluminum possesses versatility as a material, enabling it to be effortlessly shaped into different sizes and forms, which renders it suitable for decorative applications. Its lightweight characteristic, endurance, and resistance to corrosion make it an optimal selection for both interior and exterior decorative projects. Moreover, aluminum can undergo various finishes and coatings, such as powder coating or anodizing, to enhance its visual allure. These coatings present a wide array of colors, textures, and patterns, thereby facilitating boundless design possibilities. Furthermore, aluminum coils can be effortlessly manipulated into intricate designs, qualifying them for decorative elements like trims, accents, panels, or even sculptures. In summary, aluminum coils provide a cost-effective, long-lasting, and visually pleasing alternative for diverse decorative purposes.

- Q: What are the different coil winding methods for aluminum coils?

- There are several different coil winding methods for aluminum coils, each with its own advantages and suitability for specific applications. 1. Layer winding: This method involves winding the aluminum wire in a single layer around the coil mandrel. It is commonly used in low voltage applications and provides good thermal conductivity and heat dissipation. 2. Random winding: In this method, the aluminum wire is wound randomly around the coil mandrel, without any specific pattern. It is often used in high voltage applications, as it helps to reduce the risk of corona discharge and provides better insulation. 3. Concentric winding: As the name suggests, concentric winding involves winding the aluminum wire in concentric circles around the coil mandrel. This method is suitable for applications where space is limited, as it allows for a higher number of turns in a compact coil. 4. Interleaved winding: Interleaved winding involves winding multiple layers of aluminum wire in an interleaved pattern. This method helps to reduce the overall size of the coil while maintaining a high number of turns and increasing the inductance. 5. Helical winding: In helical winding, the aluminum wire is wound in a helix pattern, either at a constant pitch or with varying pitch. This method is often used in applications where a high inductance is required, such as inductors and transformers. 6. Sectional winding: Sectional winding involves dividing the coil into multiple sections and winding each section separately. This method is commonly used in large-scale applications, as it allows for easier handling and installation of the coil. Each of these coil winding methods has its own strengths and considerations, and the choice of method depends on factors such as the specific application requirements, space limitations, and desired electrical characteristics.

- Q: How do aluminum coils contribute to energy-efficient lighting systems?

- Due to its unique properties and functionalities, aluminum coils play a vital role in energy-efficient lighting systems. The conductivity of aluminum is exceptional, enabling efficient energy flow within the system. This ensures minimal energy loss during transmission, thereby maximizing the overall energy efficiency. Additionally, aluminum coils are lightweight and sturdy, making them perfect for use in lighting systems. The lightweight nature of aluminum allows for effortless installation and handling, ultimately reducing the energy needed during manufacturing and installation. Furthermore, the durability of aluminum guarantees that the coils can endure the demands of daily use without compromising performance, thereby contributing to the longevity and efficiency of the lighting system. Moreover, aluminum possesses excellent thermal conductivity, enabling efficient heat dissipation. In lighting systems, managing heat is crucial as excessive heat can diminish the lifespan and efficiency of bulbs. By utilizing aluminum coils, the heat generated by the lighting system can be effectively dispersed, minimizing the risk of overheating and ensuring optimal performance. To summarize, aluminum coils enhance energy-efficient lighting systems by providing efficient electrical conductivity, lightweight and durable construction, and effective heat dissipation. These properties help minimize energy loss, reduce energy requirements during manufacturing and installation, and enhance the overall efficiency and lifespan of the lighting system.

Send your message to us

Automotive Grade Hot Rolled Aluminum Coil 5005H14 - Aluminum Coil Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords