Hot Rolled Alloy U Channel Steel ASTM,JIS,GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Alloy U Channel Steel ASTM,JIS,GB Standard Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Dimensions: | 50*37*4.5-400*104*14.5mm | Grade: | Q235/345,SS400,A36/572/992,Gr50,S235JRG2,S235/275/335JR,ect |

| Place of Origin: | Tianjin China (Mainland) | Brand Name: | CNBM | Model Number: | RGTS-u channel |

| Shape: | U Channel | Application: | construction material or bracket | Perforated Or Not: | Not Perforated |

| Other goods: | C channel steel | Experience: | 15years | Spot goods: | Regular size have stock |

| Inspection: | SGS, BV | Delivery condition: | EXW,FOB,CFR,CIF | Quality: | Prime |

| Weight: | 5.438-71.488kg/m | Thickness tolerance: | +/-0.05mm | Model: | 5#-40# |

| Product: | channel steel |

Packaging & Delivery

| Packaging Detail: | In four circles of 6.5 steel wire rods for 6 meter goods. In six circles of 6.5 steel wire rods for 12 meter goods. Each bundle not exceeding 4mt. Also can be packing as customer's requirements |

| Delivery Detail: | within 15-30 days after receiving original L/C or deposit |

Hot Rolled Alloy U Channel Steel ASTM,JIS,GB Standard Specification

Size | 50mm*50mm-400mm*400mm |

Wall thickness | 1.5mm-25mm |

Length | 1m-12m ,by customer’s requirements |

International Standard | ISO 9001-2008 / ISO 630 / JIS / ASTM |

Standards | ASTMA53/ASTM A573/ASTM A283 /BS1387-1985/ GB/T3091-2001,GB/T13793-92, ISO630/E235B/ JIS G3101/JIS G3131/JIS G3106/ |

Materials | Q195,Q215,Q235B,Q345B,S235JR/S235/S355JR/S355SS440/SM400A/SM400B |

Product Category | Metallurgy, Mineral &Energy |

Technique | HOT ROLLED |

Packing | 1.Big OD: in bulk 2.Small OD: packed by steel strips 3.woven cloth with 7 slats 4.according to the requirements of customers |

Usage | Mechanical & manufacture, Steel structure,Shipbuilding, Bridging, Automobile chassis |

Main market | Middle East, Africa, Asia and America ,Australia |

Country of origin | China |

Productivity | 5000 Metric Tons per Month |

Remark | Payment terms :T/T ,L/C Terms of trade :FOB ,CFR,CIF ,DDP,EXW Minimum order : 20 tons Lead time :on or before 10-30 working days . |

Another Name | u channel steel , channel steel, steel channel |

Surface processing | Galvanized, coated, or as your request |

Technical | Hot rolled mild steel |

Other Service | Customized Sizes, Galvanized And punching |

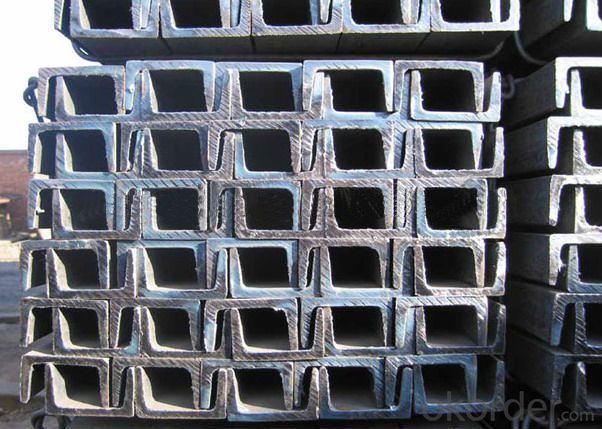

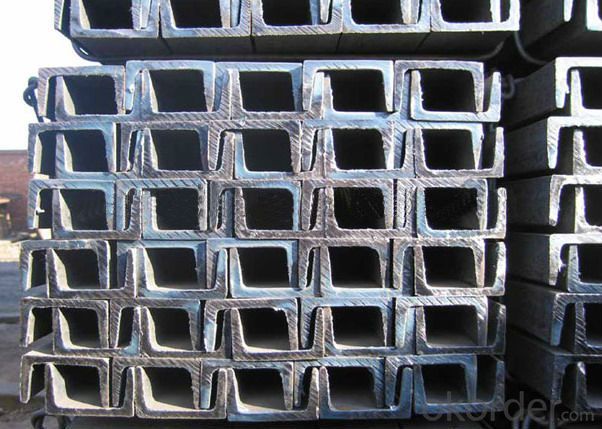

Hot Rolled Alloy U Channel Steel ASTM,JIS,GB Standard Pictures

- Q: I have three houses, the length is 7 meters, the width is 4 meters, I would like to use a 4 meter trough board to do the support, and then put concrete slabs on the channel, the two floor of the roof also do so, can I do that? If it is possible to use a large trough plate, a thick concrete slab, and a thick steel bar for concrete slabs Thank you

- Channel steel plus concrete slabs can be used as floor slabs.

- Q: What is the lifespan of steel channels?

- The lifespan of steel channels can vary depending on various factors such as the quality of the steel, the environmental conditions it is exposed to, and the level of maintenance it receives. Generally, steel channels have a long lifespan and are known for their durability and strength. With proper maintenance and regular inspections, steel channels can last for several decades or even longer. However, factors such as corrosion and wear and tear over time can affect their lifespan. It is important to protect steel channels from moisture and corrosive substances to prolong their lifespan. Additionally, regular inspections and maintenance can help identify any signs of damage or deterioration early on, allowing for timely repairs or replacements to ensure the longevity of the steel channels.

- Q: Can steel channels be used in seismic zones?

- Yes, steel channels can be used in seismic zones. Steel is a strong and ductile material that is able to withstand the forces generated during an earthquake. In seismic zones, it is important to use materials that can flex and deform without breaking or collapsing, and steel channels are specifically designed to provide this flexibility. Steel channels are commonly used in seismic design and construction because they have excellent load-bearing capacity and are resistant to bending and twisting forces. They are often used as structural members in buildings and bridges to support heavy loads and provide stability. Additionally, steel channels can be reinforced with additional measures such as bracing or cross-section enhancements to further improve their seismic performance. These reinforcements help to distribute the seismic forces more evenly and reduce the risk of failure or damage. However, it is important to note that the design and installation of steel channels in seismic zones should comply with building codes and regulations specific to the region. These codes typically provide guidelines for seismic design and dictate the minimum requirements for structural elements to ensure the safety and stability of the building. In conclusion, steel channels can be effectively used in seismic zones due to their strength, ductility, and ability to withstand seismic forces. However, proper design, installation, and compliance with building codes are crucial to ensure their performance and safety in such areas.

- Q: Can steel channels be used for modular construction systems?

- Yes, steel channels can be used for modular construction systems. Steel channels are versatile and can be easily fabricated to create modular components such as beams, columns, and support structures. They provide excellent strength and durability, making them suitable for supporting heavy loads in modular construction. Steel channels can be easily connected and integrated into modular systems, providing a flexible and efficient construction solution. Additionally, the use of steel channels allows for easy customization and adaptability to different project requirements and designs.

- Q: What are the different industry standards for steel channels?

- There are several industry standards for steel channels, which are used to ensure consistency and quality in the manufacturing and usage of these structural components. Some of the commonly recognized standards for steel channels include: 1. American Standard Channels (C) - These steel channels are defined by the American Iron and Steel Institute (AISI) and are widely used in North America. The dimensions, properties, and tolerances for American Standard Channels are specified in ASTM A6/A6M. 2. European Standard Channels (UPN) - These steel channels are defined by the European Committee for Standardization (CEN) and are prevalent in Europe. The dimensions, properties, and tolerances for European Standard Channels are specified in EN 10365. 3. British Standard Channels (BS) - These steel channels are defined by the British Standards Institution (BSI) and are commonly used in the United Kingdom. The dimensions, properties, and tolerances for British Standard Channels are specified in BS 4-1. 4. Japanese Standard Channels (JIS) - These steel channels are defined by the Japanese Industrial Standards (JIS) and are widely used in Japan and other Asian countries. The dimensions, properties, and tolerances for Japanese Standard Channels are specified in JIS G 3192. 5. Australian/New Zealand Standard Channels (AS/NZS) - These steel channels are defined by the Standards Australia and Standards New Zealand organizations and are commonly used in Australia and New Zealand. The dimensions, properties, and tolerances for Australian/New Zealand Standard Channels are specified in AS/NZS 3679.1. It is important to note that these standards may slightly differ in terms of dimensional tolerances, chemical composition, mechanical properties, and designations. Therefore, understanding and adhering to the appropriate industry standard is crucial for ensuring compatibility and compliance with the specific requirements of a particular project or application involving steel channels.

- Q: What are the different types of welding techniques used for steel channels?

- Steel channels can be welded using various techniques, each chosen based on project requirements and desired outcomes. Some common techniques include: 1. Stick welding, also known as Shielded Metal Arc Welding (SMAW), involves creating an arc between a flux-coated electrode and the workpiece. This versatile technique produces strong welds and is frequently used for steel channels. 2. Gas Metal Arc Welding (GMAW), also called MIG welding, utilizes a continuously fed wire electrode through a welding gun. A shielding gas protects the weld from atmospheric contamination. GMAW is popular for steel channels due to its high productivity and ease of use. 3. Flux-Cored Arc Welding (FCAW) is similar to GMAW, but the electrode is filled with flux, eliminating the need for a shielding gas. This technique is suitable for steel channels in outdoor or windy conditions where shielding gas may be less effective. 4. Gas Tungsten Arc Welding (GTAW), or TIG welding, employs a non-consumable tungsten electrode to create the arc. A separate filler metal is used for welding. GTAW is ideal for steel channels that require high-quality welds, providing precise control and visually appealing results. 5. Submerged Arc Welding (SAW) is an automatic process that uses granulated flux to cover the arc and weld zone. The arc is submerged under a flux layer, protecting the weld from atmospheric contamination. SAW is commonly used for thick steel channels due to its high deposition rates and deep penetration capabilities. Numerous welding techniques are suitable for steel channels. The choice depends on project requirements, desired weld quality, and the welder's skill level.

- Q: Can steel channels be custom-made?

- Indeed, it is possible to customize steel channels. Construction and engineering projects often utilize steel channels, and they can be tailored to specific requirements in terms of dimensions, length, and shape. Customization entails adjusting the size, thickness, and material grade of the steel channels to align with the project's demands. This versatility enables a vast array of applications and guarantees that steel channels can be adapted to suit diverse structural and design specifications.

- Q: Which is cheaper, the same size, ordinary channel steel and light channel steel? Price difference is not big?

- If the cost per meter, of course, is light and cheap.The specific gap, you can also refer to the hardware manual, the two are compared. Because of the tonnage, the prices are almost the same.

- Q: How are steel channels used in structural applications?

- Steel channels are widely used in structural applications due to their excellent strength and versatility. They are commonly used in the construction industry for supporting heavy loads and providing structural integrity to buildings, bridges, and other infrastructures. One of the main applications of steel channels is in the framing of buildings. They are often used as beams or columns to support the weight of floors, walls, and roofs. Steel channels are chosen for these applications because they can withstand a significant amount of load without deforming or collapsing. In addition to building frames, steel channels are also used for bracing and reinforcing structures. They can be used as diagonal braces to provide lateral stability and prevent the structure from swaying or collapsing under wind or seismic forces. Steel channels are also utilized as reinforcement in concrete structures, such as retaining walls and foundations, to enhance their strength and durability. Steel channels are also employed in the manufacturing of machinery and equipment. They provide a stable and rigid framework for heavy machinery, allowing them to operate smoothly and efficiently. In this context, steel channels are often used as support beams, frames, or structural components in various industrial applications. Furthermore, steel channels find application in the transportation industry. They are used in the construction of bridges and overpasses, where their high strength and load-bearing capacity are essential for safely carrying vehicles and pedestrians. Steel channels are also utilized in the manufacturing of railway tracks and tramways, providing a durable and stable foundation for the transportation system. Overall, steel channels play a crucial role in structural applications by providing strength, stability, and durability to various types of constructions. Their versatility and ability to withstand heavy loads make them a preferred choice in the construction, manufacturing, and transportation industries.

- Q: What are the different load-bearing tests conducted on steel channels?

- There are several load-bearing tests that are conducted on steel channels to assess their structural integrity and performance. These tests help determine the maximum load that a steel channel can bear without failure. Some of the different load-bearing tests conducted on steel channels include: 1. Tensile Test: This test measures the maximum tensile strength of the steel channel by applying a gradually increasing axial load until failure occurs. It helps assess the channel's ability to resist pulling or stretching forces. 2. Compression Test: This test determines the maximum compressive strength of the steel channel by applying a gradually increasing axial load until it buckles or collapses. It provides insights into the channel's ability to withstand compressive forces. 3. Bending Test: In this test, the steel channel is subjected to a gradually increasing load applied perpendicular to its length until it reaches its maximum bending capacity. It assesses the channel's resistance to bending or flexural forces. 4. Shear Test: The shear test measures the maximum shear strength of the steel channel by applying a force parallel to its cross-sectional area until it fails. It helps evaluate the channel's ability to withstand shearing forces. 5. Fatigue Test: This test involves subjecting the steel channel to repeated and varying loads over a specified period to simulate real-world usage conditions. It assesses the channel's resistance to fatigue and its ability to withstand cyclic loading. 6. Impact Test: In this test, a sudden and high-velocity load is applied to the steel channel to simulate impact or shock loading. It helps evaluate the channel's ability to absorb and dissipate energy without failure. 7. Buckling Test: This test is conducted to determine the critical load at which the steel channel buckles or collapses due to instability. It helps assess the channel's resistance to buckling under compressive loads. These load-bearing tests are crucial in ensuring the reliability and safety of steel channels in various applications, such as construction, manufacturing, and infrastructure. By conducting these tests, engineers can determine the load limits and performance characteristics of steel channels, allowing for informed design decisions and ensuring structural integrity.

Send your message to us

Hot Rolled Alloy U Channel Steel ASTM,JIS,GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords