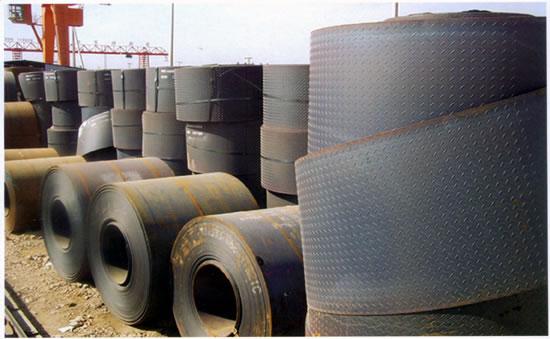

Hot rolld checkered coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The pattern roll steel patterns also known checker plate, its surface withdiamond or rib plate.

&Nbsp; steel patterns due to the surface with ribs, slide effect, can be used asbuilding floor, escalators, work frame pedal, ship deck, car floor etc..

Pattern plate specifications to the fundamental thickness (rib thicknessexcluding) said, with 2.5-8 mm 10 specifications. Diamond plate steel plate for1-3.

Class B common carbon steel rolling, the provisions of chemical composition meet the GB700 "ordinary carbon structural steel technical conditions".

Pattern plate of high no less than 0.2 times the thickness of the substrate;

Checkered steel plate according to the weight of the actual weight of deliveryor theory;

Mark example: made of Q235-A, size 4*1000*4000mm.

Peaberry pattern plate, mark it as: round bean plate Q235-A-4*1000*4000-GB/T 3277-91

Diamond pattern plate, mark it as: diamond pattern plate B 3-4*1000*4000-GB3277-82

Steel with hot-rolled state of delivery;

Checkered steel plate surface without bubble, scar, crack, folding andinclusion, plate without delamination.

The surface quality is divided into two levels:

The general accuracy: steel surface with a thin layer of oxide scale and rustallowed, due to other local defects on the surface of oxide scale formed offrough and height or depth exceeds the allowable deviation of the ancient.

Burr height is not obvious and not more than the individual trace lines highallows patterns. The largest area of a single defect pattern with the square of the length of not more than.

High precision: steel surface with a thin layer of oxide scale, allowing the rust and the height or depth of no more than other local defects of half thethickness tolerance.

Pattern intact, a height of not more than half of the tolerance of thickness of the local slight burr allowed patterns.

- Q: I'm looking for a good source as to the 'structural formula' of steel. I'm not quite sure if that's what it's actually called, but here's a link to what I'm looking for.

- There is none. There is no steel molecule, so one can't draw its molecular structure. Most steel has a body-centered cubic (ferrite) crystal structure (some stainless steels are face-centered cubic - austenite). Depending on the alloying elements, it's typically a random solid solution. Most of the lattice sites will be occupied by iron atoms, but other atoms from the alloying components will replace random sites. Smaller atoms like carbon are in the interstitial points, meaning they fit in between the larger atoms. Depending on the alloy and the processing conditions, you can also get a mix of phases, including more complex structures like cementite (iron carbide), molybdenum carbide, manganese sulfide, or martensite (a non-equilibrium tetragonal phase).

- Q: Molton is formed at 2800 F. Thats a fact. Now jet fuel at its hottest is 1800. Where does the other 1000 degress come in? And it was found at the WTC 7 site. Was this hit by a plane? A simple fire COULD NOT produce molton. This is a fact. Molton is formed during controlled demoliton of a building since all the bombs in the buiding go off and its very very hot. The fact there was MOLTON at the site is shocking to some since it is IMPOSSIBLE for molton to form from jet feul alone. Impossible. It needed another source. Now the claim that I'll get is that it weakened the stell but then we would find weak steel not molton. Why do you seem to throw this off of your shoulder? Do you not want to belive it? I'm no jet fuel guy but I know you cannot make molton by using just jet fuel. This is really proof that 9/11 was an inside job.

- People who believed the buildings collapsed because of the planes are far far off. 1. Burning jet fuel CANNOT melt steel - FACT! 2. The twin towers were built to withstand a hit from a Boeing 707 - FACT 3. NORAD didn't respond - for the first time EVER! - FACT! 4. The pentagon has the most CCTV cameras than any other buildings in the world and they only release the tape which the plane is not visible, they also confiscated the tape from the store opposite which would have shown the plane - if it existed. State sponsored terrorism has been around for along tI'me, im surprised at how many people still believe the official story.

- Q: How do steel coils contribute to the energy storage industry?

- Steel coils play a vital role in the energy storage industry by serving as a key component in large-scale energy storage systems such as pumped hydro storage and compressed air energy storage. These coils are used in the construction of storage tanks and pressure vessels, which are essential for storing and releasing energy on demand. Additionally, steel coils are also utilized in the manufacturing of battery systems used in grid-scale energy storage applications, providing structural support and ensuring safety and reliability.

- Q: So here's the deal:I recently bought McCann's Instant Steel-Cut Oatmeal, and I'm wondering about any possible nutritional differences between the instant and regular stove-top. In case you haven't seen it, instant steel-cut comes in individual packets and is cooked only by adding boiling water, the same as instant rolled oatmeal (i.e. Quaker).When I asked about instant vs. stove-top rolled oats, my doctor said there are no significant nutritional differences, but since the main health appeal of steel-cut is the coarse grain, it doesn't seem possible for the finer ground instant to be as nutritious.I can't find much info about this, so any help is appreciated!

- Most people who are used to rolled oats have a very hard time adjusting to steel cut oats that are cooked only 30 minutes. For many, it's not much different than eating them raw. (Raw, soaked oats is called cram. Having to eat uncooked oats, as only the poorest would do, gives us the expression 'to cram it down your throat'.) Better still is to cook them thoroughly at night then reheat portions for breakfast if you're in a hurry. They'll keep about five days at a time under refrigeration. Any small nutritional loss from longer cooking is more than compensated by the better digestibility of well-cooked oats. That is, the nutrition is wasted if the oats pass undigested through the body. For most of us, that would happen. Indeed, we are not cows. Neither are we horses. People need to cook their oats.

- Q: Im in the process of replacing the gutters/down spouts on my house. The top of the house is four sided. The bottom level has a porch area with 3 sides, two smaller roofs in the back, and one small roof on the side with all stainless steel gutters. A two story house. Not sure of the demensions. They were made at a Steel Mill where the previous owner, worked.This guy wants to buy the stainless gutters but I need to know the market value of this steel and offer him a price. Can someone tell me what I can sell it for? Does it go by the pound? Foot? Can you give me an idea please? Theres a lot of it! I have no clue what to do! Thanks!

- Depends on the company but you'd probably get a decent amount of money. Try searching different sites.

- Q: Is it faster to smith steel or mithril in Rinescape assuming I'm going to mine everything myself?Mining level: 76Smithing level: 55

- i think steel

- Q: I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- If you want a good quality knife, stay away from Stainless, I would suggest one that is a mix of high and low carbon steel, high carbon holds the edge, but is brittle, low carbon is more malleable, which prevents from breaking when used.

- Q: What are the different types of steel coil handling attachments?

- In industrial settings, various types of steel coil handling attachments are commonly utilized. These attachments are designed to handle steel coils of different sizes and weights in a safe and efficient manner. One commonly used attachment is the coil lifter. Made of durable steel, this attachment securely grips the steel coil. It is equipped with adjustable arms or hooks that can be positioned to fit the specific size and shape of the coil. To ensure safe transportation, coil lifters are often used in conjunction with cranes or other lifting equipment. Another frequently seen attachment is the coil grab. Similar to a coil lifter, it securely grips and lifts steel coils. However, coil grabs have a more compact design and are generally used in applications where space is limited. They can be operated manually or attached to a crane or forklift. Additionally, there are coil tongs specifically designed for handling smaller steel coils. These tongs are commonly used in manufacturing or processing facilities where coils need to be lifted and moved within confined spaces. With adjustable jaws, coil tongs provide a secure grip on the coil. In certain cases, magnetic attachments are employed for handling steel coils. These magnets attract and hold onto the steel, allowing for easy lifting and transportation. Magnetic attachments are particularly useful in environments with extreme temperatures or when the steel coils are coated. It is important to consider the size, weight, and specific requirements of the application when selecting a steel coil handling attachment. Industrial equipment suppliers can offer guidance in choosing the most suitable attachment for a particular situation.

- Q: What's the length of a coil of cold rolled steel? Is there a standard?

- And the length has a lot to do with the thickness. So the total length of the volume is not good.

- Q: engineering sloutions related to steel fabrication

- not okorder /

Send your message to us

Hot rolld checkered coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords