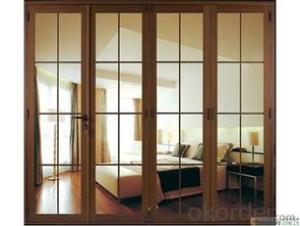

hot luxurious appearance aluminium wood folding door

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Profile:

A. Alloy: GAluminum Brand

B. Wall thickness: 1.2mm--2.0mm

C. Finishing: Anodize Sliver & Bronze / Powder Coating Any Color/ Electrophoresis Sliver& Champagne/ PVDF

D. With Thermal Break, More Energy Saving/ Normal / Aluminum Wood Material, Wood Indoor & Aluminum Outdoor

2. Glass:

A. Thickness: Single 5mm -12mm, Double Glazing 5mm+6A+5mm, 5mm+9A+5mm, 5mm+9A+6mm, 6mm+12A+6mm

B. Color: According to your needs.

C. Special: Low-e / reflective / tempered / float

3. Hardware: Made in China / Made in Germany

4. Accessories:

A. Use Glass Silicone / Use Glazing Rubber

B. Stainless steel accessories

5. Production standard: Make according to your detail requirements.

- Q: That is, the calculation of the box and the method of the fan, please write a careful point I was an apprentice would like to ask the teacher and do not want to ask the master please help out Thank you!

- The general sliding window to pull out the width of the addition of a 2 is equal to the width of the fan, but generally minus 1-2 mm will be better

- Q: Bathroom door price is probably how much? Aluminum door that kind of.

- his is not in accordance with how much money is a square meter is installed, the market is estimated to be 350-1500 a square range. I suggest you look to the building materials market, the best choice for more well-known and cost-effective brand. Like Pai Ya this brand, in the aluminum, metal, glass and other materials are very experienced, because in the process technology is more mature, relatively low manufacturing costs, naturally cheaper, the price of about 700-800 per square meter. Of course, the brand is not the same, the price is not the same.

- Q: Ask you, China aluminum doors, windows of the conventional size, please detailed and accurate answer, thank you! The The anxious! Thank you, China, Li Gong, but I want is that the specific size, such as windows: 300-1600mmx500-1600mm. Such a detailed format. Please continue to add Kazakhstan ~ anxious, first thank you, the score can be added. ) Lake ㄣ water, but why people on this, so I asked ah

- General residential building, the height of the window is 1.5m, plus windowsill height 0.9m, then the window from the floor 2.4m, also left 0.4m structure height The In public buildings, windowsill height from 1.0 ~ 1.8m range, open to the public walkway sash, the bottom height should not be less than 2.0m. to The height of the window is based on lighting, ventilation, space image and other requirements to decide, but pay attention to the problem of high window stiffness, if necessary, Set a beam or "Fight Tang". In addition, the windowsill below 0.8m, should take protective measures. ?? Modern glass curtain wall, the height of the whole piece of glass has been more than 7.2m, it is not part of the scope of the general window. Window width ?? Window width generally from 0.6m, wide to constitute a "window", but pay attention to the use of the width of the window, the left and right next door room noise problems As well as sliding the sling of the sliding range of the problem, but also pay attention to the wide window between the wide window will cause the glare on the wall, the classroom, exhibition room are Inappropriate.

- Q: Looking for Metal doors for Steel Entry Doors,Exterior Steel Doors,Metal Doors,Stanley Steel Exterior Doors Commercial Steel Doors,Steel Doors Frames,Residential Steel Entry Doors all at one place.

- Special order at Home Depot...

- Q: Do an aluminum alloy doors and windows processing and installation company to go through what procedures

- The first step, the company name 1, to provide a copy of all the shareholders ID card 2, the proportion of corporate and partner investment 3, the preparation of the company name 1-5 4, the development of the company's business scope of the main project 5, the company address to determine The second step, to provide registration information: 1, all the shareholders of the ID card 2, housing lease contract 3, housing property certificate 4, open a bank account and proof of funding 5, verified by the accounting firm and issued a report The third step, reported to the Trade and Industry Bureau review and approval 1, reported to the Trade and Industry Bureau preliminary examination 2, submitted to the Trade and Industry Bureau for approval, 3, for business license (is a copy) The fourth step, for business code certificate The fifth step, for the national tax, land tax tax registration certificate Answer: qq627440408 | three | 2017-6-14 19:31 The first step, the company name The second step, to provide registration information: The third step, reported to the Trade and Industry Bureau review and approval The fourth step, for business code certificate The fifth step, for the national tax, land tax registration certificate

- Q: Does anyone know if I can replace 2007 wrangler half doors with full metal doors? Ive been looking around and cant seem to find any full doors so im not sure. And if you can, does anyone know where i can find them in aftermarket sales?

- hello and yes these doors are very interchangable im in the opsite position i have full doors and are lookin for the half doors and looking to trade or sell them! please email me back

- Q: Bathroom of titanium and magnesium alloy door package or a good double package

- Bathroom titanium magnesium alloy door is generally a single package, the back of a tile, do not need to package, if the gap between the ceramic tile and the door is too large, it is generally used polymer or aluminum alloy, stainless steel flat bar pressure Single and double the price of the package because of the different geographical differences, we are here a single package is 80 yuan, double package 150

- Q: Open an aluminum alloy doors and windows factory early need to prepare what?

- Site equipment personnel doors and windows materials (main material, auxiliary materials) mainly have engineering

- Q: Ordinary aluminum alloy door how much money?

- The door should be counted in square meters

- Q: Titanium magnesium alloy door 1.0 thickness enough?

- If the material is thick enough, in fact, the main open the door is rust and lubrication, open pull easy, the door structure will be very durable. So must be done rust and lubrication. The installation master is often too lazy to apply grease. Otherwise a few months began to rust, abnormal sound and slippery. It is best to use fully synthetic grease, with food safety certification. Tiger hotterube or Krupp can be, colorless and transparent, low temperature, water and antifreeze, odorless, durable, peach leopard leopard with 130 grams of toothpaste-like packaging, easy to use.

Send your message to us

hot luxurious appearance aluminium wood folding door

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

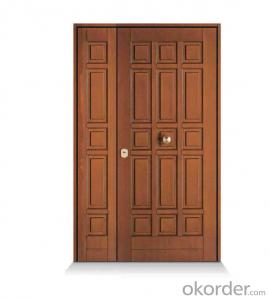

Similar products

Hot products

Hot Searches