Hot Dipped Galvanized steel Pipe Gold supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Gold supplier Hot Dipped Galvanized steel Pipe Details

| Thickness: | 0.45 - 15 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 219 mm |

| Place of Origin: | Tianjin China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Structure Pipe,Industry |

| Technique: | ERW | Certification: | ISO9001,ISO | Surface Treatment: | Galvanized |

| Special Pipe: | Thick Wall Pipe | Alloy Or Not: | Non-alloy | Brand Name: | TJXAHY |

| packing: | as your requirements | galvanized steel pipe: | galvanized steel pipe | galvanized pipe BS 1387-1985: | galvanized pipe BS 1387-1985 |

| hot dip galvanized pipe: | hot dip galvanized pipe | Samples: | can be provided | product name: | Gold supplier !!!!! Hot Dipped Galvanized Pipe |

| Name: | Hot Dipped Galvanized steel Pipe | Grade: | 10#,20#,45#,16Mn,A106(B,C),A335, P11,A53(A,B),Q195,Q215,Q235,Q345,10#-45#,A53-A369,Q195-Q345 | Standard: | ASTM A106-2006,BS |

Packaging & Delivery

| Packaging Detail: | standard seaworthy packing |

| Delivery Detail: | 7--20days after receiving the deposit |

Gold supplier Hot Dipped Galvanized steel Pipe Specification

O.D | O.D tolerance | W.T | Thickness Tolerance |

10.3--219MM | ±0.03 | 0.6--10MM | ±0.02 |

Length | 2--12M,according to customers' requirements | ||

Zinc coating | 275--350g/m2 | ||

International Standard | ISO 9001;2008 | ||

Standard | ASTM A 53/BS 1387-1985 | ||

Material | Q195/Q215/Q235/Q345 | ||

Product Category : | Metallurgy,Mineral & Energy | ||

Technique: | Welded | ||

Usage | 1.For low pressure liquid delivery such as water,gas and oil 2.For construction,e.g building greenhouse | ||

Main market: | Middle east,Africa,North and South America,East and West Europe,South and southeast Asia,Australia | ||

Place of Origin | China | ||

HS code: | 7306309000 | ||

Remarks | 1)Payment term:T/T 2)Trade Terms:FOB/CFR/CIF 3)Minimum quantity of order:25 MT (25,000KGS) 4)Delivery period:10 to 30 Days. | ||

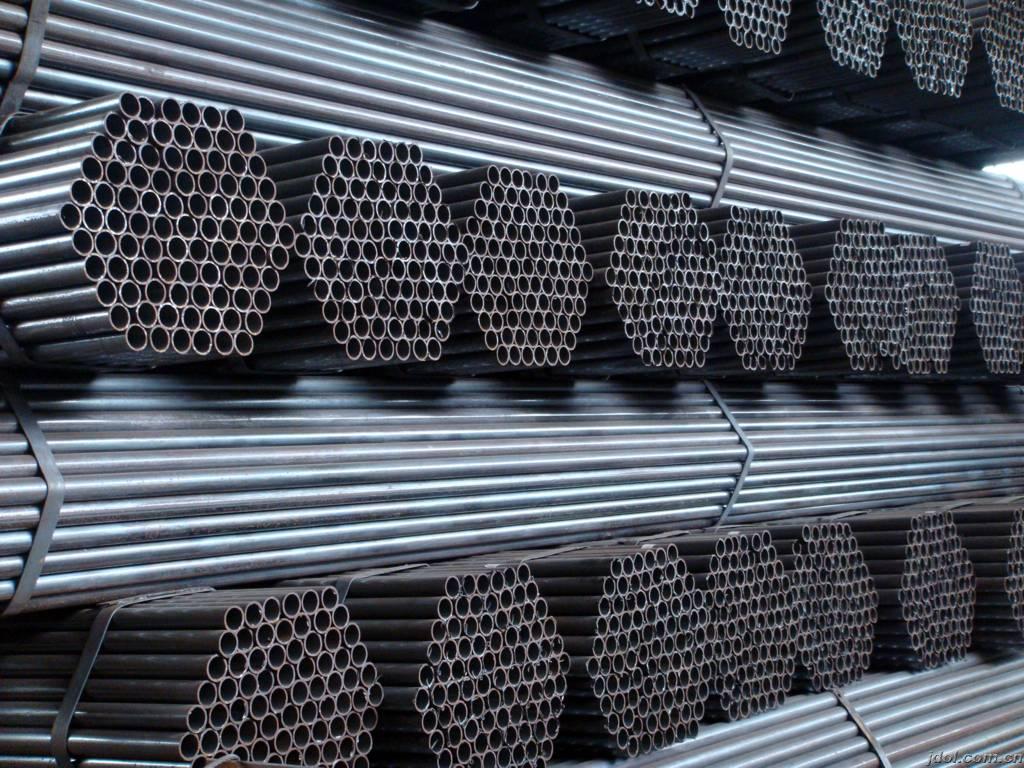

Gold supplier Hot Dipped Galvanized steel Pipe Pictures

- Q: Can steel pipes be used for oil and gas pipelines?

- Yes, steel pipes can be used for oil and gas pipelines. Steel pipes are commonly used in the oil and gas industry due to their strength, durability, and resistance to corrosion. They can withstand high pressure and extreme temperatures, making them suitable for transporting oil and gas over long distances.

- Q: Can steel pipes be used for underground cooling systems?

- Indeed, underground cooling systems can make use of steel pipes. Thanks to their durability, strength, and resistance to corrosion, steel pipes are widely employed in numerous applications, including underground cooling systems. They are adept at handling the rigorous demands of cooling systems, such as high pressure and temperature requirements. Moreover, steel pipes can be conveniently installed and maintained by means of welding or threading them together. Nonetheless, it is crucial to ensure that the steel pipes are adequately coated or insulated in order to avert corrosion and uphold heat transfer efficiency.

- Q: How are steel pipes threaded?

- Steel pipes can be threaded using a process called threading. Threading is the process of creating screw-like grooves on the outer surface of the pipe, which allows it to be connected to other pipes or fittings using threaded connections. There are several methods for threading steel pipes, including manual threading, electric threading machines, and hydraulic threading machines. In manual threading, a handheld pipe threading tool called a die is used. The die is placed on the outside of the pipe, and the pipe is rotated while pressure is applied to create the threads. This method is suitable for small diameter pipes and is typically used for on-site repairs or in small-scale operations. Electric threading machines are commonly used for larger diameter pipes. These machines consist of a motor-driven spindle, which rotates the pipe, and a die head that holds the threading dies. The operator simply feeds the pipe into the machine, and the threading dies cut the threads onto the pipe automatically. Hydraulic threading machines are similar to electric threading machines but use hydraulic power to rotate the pipe and create the threads. These machines are typically used for larger diameter pipes or in heavy-duty applications. Regardless of the method used, it is important to ensure that the pipe is properly prepared before threading. This may involve cleaning the pipe, removing any burrs or sharp edges, and applying a lubricant to reduce friction during the threading process. Overall, threading is a common and efficient method for creating threaded connections on steel pipes. It allows for easy assembly and disassembly of pipes and fittings, making it a popular choice in various industries such as plumbing, construction, and oil and gas.

- Q: Galvanized steel pipe, PPR pipe, PE pipe, U-PVC pipe and HDPE double wall corrugated pipe and what is the difference between the characteristics of

- PE pipe, polyethylene pipe, the past is also commonly used in low temperature water, but because of its short life now use less prone to aging, more PE material for the production of plastic bags;

- Q: How are steel pipes insulated to prevent condensation?

- Steel pipes are typically insulated using materials such as foam or fiberglass wraps, which act as a barrier between the cold pipe surface and the surrounding air. This insulation prevents the formation of condensation by reducing heat transfer and maintaining the pipe temperature above the dew point of the air.

- Q: The plastic pipe and steel pipe difference

- Plastic pipe and plastic inner coating, and coated inside and outside. (of course, some are epoxy coated, and some are PE).The plastic tube is one kind of steel pipe, steel plastic pipe has many types, including plastic, plastic, and plastic coated, and epoxy, which are known are steel tubes.

- Q: Welded and seamless steel pipe how to distinguish?

- Different price:Because the production process of seamless steel tube is more complex, so the price is more expensive than a seamed steel pipe, and pipe joints mainly adopts steel (steel) two welded, fixed price, the most widely used are.

- Q: What is the role of steel pipes in the construction of bridges?

- Steel pipes play a crucial role in the construction of bridges as they are used for various purposes such as supporting the weight of the bridge, providing structural integrity, and allowing for the flow of fluids or gases. Steel pipes are often used as support columns or piles in bridge foundations, providing stability and strength to the structure. They are also used for constructing bridge piers, trusses, and beams, ensuring the bridge can withstand heavy loads and forces. Additionally, steel pipes can be utilized for the transportation of water, gas, or other fluids across the bridge, making them essential for the overall functionality and longevity of the bridge.

- Q: What is a tight steel tube?

- The tight steel tube is called "galvanized steel pipe with sleeve connection" or "flat pipe of steel metal for electrical installation". JDG. The utility model relates to a novel protective conduit for an electric circuit. The connecting sleeve and the metal accessory are provided with a wire pipeline composed of screw fastening connection technology, and the utility model does not need to do cross grounding, welding and covering, and the appearance is silvery white or yellow.

- Q: What are the advantages of using steel pipes over other materials like PVC or copper?

- There are several advantages of using steel pipes over other materials like PVC or copper. Firstly, steel pipes have superior strength and durability, making them suitable for high-pressure applications and extreme weather conditions. Secondly, steel pipes have excellent corrosion resistance, ensuring a longer lifespan compared to PVC or copper. Additionally, steel pipes offer better fire resistance, making them safer for certain applications. Lastly, steel pipes have higher thermal conductivity, allowing for efficient heat transfer.

Send your message to us

Hot Dipped Galvanized steel Pipe Gold supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords