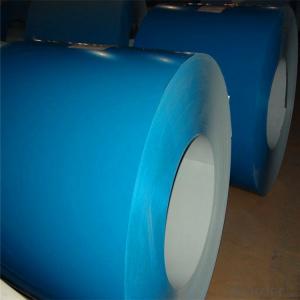

HOT DIPPED GALVANIZED STEEL COL ZINC COATING STEEL COILS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Dipped Galvanized Steel Coil

Specifications

1,hight-quality products

2,competitive price

3,perfect post-sale service

Product Name | Hot Dipped Galvanized Steel Coil |

Certification | ISO9001:2008 |

Standard | JIS 3302 / ASTM A653 / EN10143 |

Grade | DX51D,SGCC,ect |

Zinc Coating | galvanized(GI) |

Zinc thickness | 40-600g/m2 |

Thickness | 0.12mm~5.0mm |

Width | 600mm-1250mm |

Coil ID | 508mm/610mm |

Coil weight | 3-8 MT |

Technique | Hot rolled/cold rolled/galvanized |

Surface structure | Mini/regular/big/zero spangle, Chromate treatment/chromate-free treatment/untreated unoiled/oiled |

Special Application | Wear resistant steel, high- strength steel plate |

Advanced | Advanced production technology Excellent r&d management team Sophisticated production equipment Constant pursuit of high-quality goods First-class after-sales service |

- Q: What are the safety precautions while handling steel coils?

- To prevent accidents and injuries when dealing with steel coils, it is crucial to adhere to specific safety measures. Consider the following key precautions: 1. Personal Protective Equipment (PPE): It is essential to wear suitable PPE, including steel-toed boots, safety glasses, gloves, and a hard hat. This protective gear will safeguard against potential hazards like falling objects, sharp edges, and flying debris. 2. Training and Proper Lifting Techniques: Ensure that workers handling steel coils have received thorough training in safe lifting techniques. This involves lifting with the legs, maintaining a straight back, and avoiding twisting motions. By utilizing proper lifting techniques, the risk of back strains and injuries can be minimized. 3. Secure Storage and Stacking: When storing or stacking steel coils, ensure they are placed on a stable and level surface. Employ appropriate storage equipment like racks or pallets to prevent coils from shifting or falling. Stack the coils securely to prevent toppling or collapsing. 4. Inspection and Maintenance: Regularly inspect steel coils for any defects, such as sharp edges, loose bands, or damaged packaging. Avoid handling coils that appear damaged or unstable. Conduct regular maintenance on equipment like forklifts or cranes used for moving the coils to ensure safe operation. 5. Communication and Signaling: Implement clear communication and signaling protocols among workers involved in handling steel coils. This can involve hand signals or radio communication to coordinate movements and prevent accidents, especially in areas with limited visibility. 6. Load Limits and Capacity: Be aware of the load limits and capacity of the equipment used to move steel coils, such as forklifts or cranes. Overloading equipment can lead to instability, tipping, or collapse, thereby increasing the risk of accidents and injuries. 7. Proper Lashing and Securing: When transporting steel coils, employ appropriate lashing and securing methods to prevent movement or falling during transportation. This may entail using straps, chains, or other restraints to keep the coils securely in place. 8. Emergency Preparedness: Establish an emergency plan in case of accidents or injuries. Ensure that workers are trained in first aid and that emergency response equipment, such as fire extinguishers and first aid kits, are easily accessible. By adhering to these safety precautions, the likelihood of accidents and injuries when handling steel coils can be significantly reduced, creating a safer work environment for all individuals involved.

- Q: How are steel coils used in the production of automotive wheels?

- Steel coils are used in the production of automotive wheels as they are shaped and molded into rims before being welded or bolted onto the wheel hubs. The steel coils provide the necessary strength and durability required for the wheels to handle the weight and stresses of the vehicle, ensuring a safe and reliable driving experience.

- Q: .Yea, so I just saw the old Conan movie with Arnold. Good movie, but I still don't get it. What IS the riddle of steel???I get that like from the begining Conan's dad is like telling him a story about Crom and giants, and people got steel once Crom killef the giants. Then, later on in the movie Conan's talking to his lil' asian homie, and Conan tells him that when he dies... he'll go before Crom, and Crom will ask him what the riddle of steel is, and if he doesn't know it he'll get kicked out of barbarian heaven!But, what is the riddle of steel???C'mon guys... I want to in to barbarian heaven! LolBut, seriously though... what us it???.

- Riddle Of Steel

- Q: I need help! Please help, I'm in Chemistry, and me and my friend Lucy are making a presentation on steel and iron, so how is steel manufactured? Thank you. :D

- The steel consists of ( Iron ) and another matter... but the popular one is iron+carbon / iron+silver - When iron is smelted from its ore by commercial processes, it contains more carbon than is desirable. To become steel, it must be melted and reprocessed to reduce the carbon to the correct amount, at which point other elements can be added. This liquid is then continuously cast into long slabs or cast into ingots. Approximately 96% of steel is continuously cast, while only 4% is produced as cast steel ingots. The ingots are then heated in a soaking pit and hot rolled into slabs, blooms, or billets. Slabs are hot or cold rolled into sheet metal or plates. Billets are hot or cold rolled into bars, rods, and wire. Blooms are hot or cold rolled into structural steel, such as I-beams and rails. In modern foundries these processes often occur in one assembly line, with ore coming in and finished steel coming out. Sometimes after a steel's final rolling it is heat treated for strength, however this is relatively rare.

- Q: how much pressure can steel withstand? and how much pressure can concrete withstand? per m3 or cm3? thanks

- About all I remember is concrete can stand tremendous compression but almost no stretch .

- Q: How are steel coils used in the production of electrical systems?

- Steel coils are used in the production of electrical systems as they serve as the core component of transformers and inductors. They provide a magnetic field necessary for the efficient functioning and transformation of electrical energy.

- Q: Steel resist tension. Then why we provide steel in compression zone ?

- There are several reasons to add compression steel. Keep in mind, supported steel (meaning it can't buckle) resists compression as well. Compression steel helps reduce long term deflections. Concrete creeps under sustained loads. Steel lessens the compression, meaning less sustained compressive stress to cause creep deflection. It makes members more ductile. Since the steel takes some of the compressive stress, the compression block depth is reduced, increasing the strain in the tension steel at failure, resulting in more ductile behavior (the moment at first yield remains largely the same with compression steel added, but the increase in capacity after yield is significant). Compression steel insures that the tension steel yields before the concrete crushes, meaning it helps change the failure mode to tension controlled. It makes beams easier to construct. With bars in the top and bottom, you have longitudinal reinforcement in all 4 corners of the shear stirrups to keep them in place when pouring the concrete. Also, for continuous members, its often easier to run your negative moment steel the full length of the beam rather than trying to cut it off in the positive moment regions. Serviceability concerns. You're going to end up putting steel in that region anyway to for temperature and shrinkage.

- Q: How are steel coils used in the production of industrial tanks?

- Steel coils are used in the production of industrial tanks as they are rolled into cylindrical shapes and welded together to form the tank's body. The coils provide a durable and strong structure, capable of withstanding high pressure and temperature conditions. Additionally, the steel coils can be customized to meet specific size and shape requirements, allowing for efficient and cost-effective tank production.

- Q: What are the common applications of cold-rolled stainless steel coils?

- Due to their unique characteristics and versatility, cold-rolled stainless steel coils find widespread use in various industries. The following are some common applications of these coils: 1. Automotive Industry: Manufacturing parts like exhaust systems, trim, and body panels in the automotive industry extensively utilize cold-rolled stainless steel coils. The corrosion resistance and aesthetic appeal of stainless steel make it an ideal choice for these purposes. 2. Construction Industry: The construction industry heavily relies on stainless steel coils for roofing, cladding, and structural components. The durability, strength, and resistance to corrosion of cold-rolled stainless steel coils make them a preferred material in building and infrastructure projects. 3. Kitchen Appliances: Kitchen appliances such as refrigerators, ovens, and dishwashers commonly incorporate stainless steel coils. The hygienic properties, easy maintenance, and sleek appearance of stainless steel make it popular for these applications. 4. Food Processing Industry: In the food processing industry, cold-rolled stainless steel coils are extensively used due to their non-reactive nature and resistance to corrosion. These coils are used for manufacturing equipment, storage tanks, and conveyor systems in food processing plants. 5. Medical Equipment: Cold-rolled stainless steel coils are widely employed in the medical industry for manufacturing surgical instruments, implants, and medical devices. The biocompatibility, strength, and resistance to corrosion of stainless steel make it suitable for these critical applications. 6. Oil and Gas Industry: The oil and gas industry utilizes cold-rolled stainless steel coils in various applications, including pipelines, storage tanks, and offshore platforms. The high resistance to corrosion and extreme temperature conditions make stainless steel a reliable choice in this demanding industry. 7. Aerospace Industry: Stainless steel coils find use in the aerospace industry for manufacturing aircraft components, engine parts, and structural elements. The lightweight yet high-strength properties of stainless steel make it an ideal material for these applications. In summary, cold-rolled stainless steel coils have diverse applications across industries such as automotive, construction, kitchen appliances, food processing, medical, oil and gas, and aerospace. The unique combination of durability, corrosion resistance, strength, and aesthetic appeal makes stainless steel coils a preferred choice in various industrial sectors.

- Q: i have a pocket knife that is stainless steel that my mom found in the parking lot and i am wondering if oxygen peroxide will rust it? and if it dose is there something else i can use to get rid of the rust?

- Stainless does rust over time (EVERYTHING rusts it's called oxidation) Whenever something comes in contact with oxygen, the molecules will bond with the oxygen to form an oxide. Iron form iron oxide or rust which is reddish brown, apples turn brown after several minutes after it's been bitten. It all depends on the type of material used to manufacture the stainless. Stainless is made up of .2%-2% carbon, 11%%-28.5% chromium and iron. Some stainless is further advanced by adding other metals like nickel, molybdenum or niobium. Most stainless pocket knives are either normal steel coated with stainless or a cheaper form of stainless (it will have a high 300 number or very low 400 stamped on it). Other time, stainless will rust when a form of iron scratches the surface and contaminates the stainless, this is easily treatable if you get it quickly. Oxygen peroxide should not rust it, since the oxygen has already bonded with each other to form peroxide (2 oxygen molecules). It's the simplest form, but not the most stable (which means it could make your knife rust further). But I recommend steel wool or a scratch pad used to clean cook where (usually green or brown) to remove the rust.

Send your message to us

HOT DIPPED GALVANIZED STEEL COL ZINC COATING STEEL COILS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords