Hot dipped Aluzinc Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

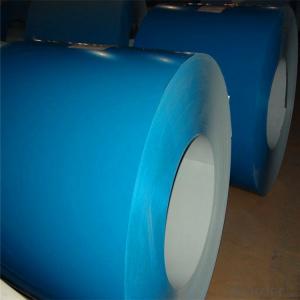

PREPAINTED ALUZINC STEEL COIL

Specification:122O*O.45

Steel Grade & Standard: CG20140923

AZ150

Surface Treatment: non-chromate, oiled

Coil ID:508mm Coil Weight:6-10MT

Package Type:EYE TO SIDE

Thickness Tolerance:+/-0.02mm Width Tolerance:+/-5mm

Zinc Coating Tolerance:-/+10g/m2

- Q: What are the factors affecting the lifespan of steel coils?

- The lifespan of steel coils can be influenced by various factors. To begin with, the quality of the steel utilized in the coil manufacturing process plays a significant role. Steel of high quality, possessing appropriate composition and metallurgical properties, tends to have a longer lifespan in comparison to lower-quality steel. Moreover, the environment in which the steel coils are stored and utilized also impacts their longevity. Exposure to extreme temperatures, humidity, and corrosive substances can result in the degradation and corrosion of the coils, ultimately reducing their lifespan. To prolong the lifespan of the coils, it is crucial to maintain proper storage conditions, including controlled temperature and humidity levels. Additionally, the handling and transportation of steel coils can have an effect on their lifespan. Mishandling, such as dropping or improper loading and unloading, can lead to physical damage, causing premature failure of the coils. Similarly, rough transportation conditions characterized by excessive vibration or impact can contribute to coil deterioration and a reduction in their lifespan. Furthermore, the maintenance and care of the steel coils also play a role in determining their lifespan. Regular inspections, cleaning, and maintenance practices aid in the identification and resolution of potential issues before they escalate into major problems. Moreover, applying protective coatings or treatments to the coils can prevent corrosion and extend their lifespan. In summary, the lifespan of steel coils is influenced by a combination of factors, including steel quality, storage conditions, handling and transportation, and maintenance practices. It is essential to consider these factors and implement appropriate measures to ensure the longevity of the coils.

- Q: What is the role of steel coils in the production of industrial machinery?

- Steel coils play a crucial role in the production of industrial machinery as they are used as raw material for manufacturing various components and parts. These coils are typically cut, shaped, and formed into desired shapes and sizes to create structural frames, panels, gears, shafts, and other vital elements of machinery. The high strength and durability of steel make it an ideal choice for withstanding heavy loads, vibrations, and harsh operating conditions, ensuring the reliability and longevity of industrial machinery.

- Q: i cant find this stuff about steel:conductivitystrengthcorrosion resistancecommon applicationsif you know of any interesting facts, i could use those 2!thanx!

- go okorder and search for steel.......

- Q: How are steel coils loaded onto trucks or containers?

- Steel coils are typically loaded onto trucks or containers using specialized equipment such as coil lifters or coil hooks. These devices safely secure the coils and allow them to be lifted and positioned onto the truck or container. The coils are then secured in place using straps or other restraints to prevent them from shifting during transportation.

- Q: What are the different types of steel coil cuts?

- There are several different types of steel coil cuts, including hot-rolled, cold-rolled, galvanized, and stainless steel coil cuts.

- Q: I need to penetrate steel on my car but don't know which bit to use. Are there special bits for steel?

- Yes. But normal drills are god for steel. Most good regular twist drills sold will go through mild steel no problem. Just so long as you don't buy a wood auger or a carbide-tipped concrete drill

- Q: How are steel coils inspected for color consistency?

- Steel coils are inspected for color consistency through visual inspection by trained personnel. They compare the color of the coils against a color standard to ensure uniformity and consistency across the entire batch.

- Q: Will hot dip galvanizing affect the properties of the steel

- depends on what your are dipping...i.e what its composition and properties were, was it a spring steel prior?

- Q: Is cold steel actually steel? Does it hurt? Why is it used in training? First one to goodly answer those questions gets 10 points.

- Cold steel was an expression originally used to signify a sword. From feeling the cold of the blade as it entered the body.

- Q: What are the common surface treatments for galvanized steel coils?

- The common surface treatments for galvanized steel coils include passivation, chromate coating, and oiling. Passivation is a process where a thin layer of protective material, such as zinc phosphate or chromate, is applied onto the galvanized steel surface. This layer helps to enhance the corrosion resistance of the steel by providing a barrier against moisture and atmospheric elements. Passivation also improves the adhesion of subsequent coatings or paints that may be applied to the steel. Chromate coating, also known as chromating or chromate conversion coating, involves the application of a thin layer of chromate onto the galvanized steel surface. This coating provides an additional layer of protection against corrosion and improves the appearance of the steel. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is another common surface treatment for galvanized steel coils. This involves the application of a thin layer of oil onto the surface of the steel, which helps to prevent the formation of rust and corrosion during storage and transportation. Oiling also provides temporary protection against moisture and other environmental factors until the steel is further processed or used in its final application. These surface treatments are commonly used to enhance the performance, durability, and appearance of galvanized steel coils, ensuring that they can withstand harsh conditions and maintain their quality over time.

Send your message to us

Hot dipped Aluzinc Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords