Hot-dip Zinc Coating Steel Sheets in Coils of Prime Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

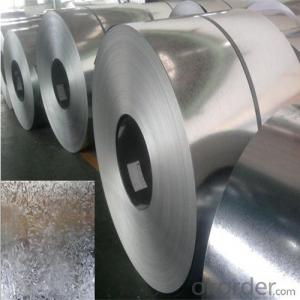

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Can steel coils be used in the production of aerospace components?

- Yes, steel coils can be used in the production of aerospace components. Steel coils are commonly used in the manufacturing of various aerospace components such as structural frames, fasteners, landing gear, and engine parts. The high strength, durability, and versatility of steel make it a suitable material for these critical components in the aerospace industry.

- Q: What is the average tensile strength of a steel coil?

- The average tensile strength of a steel coil can vary depending on the specific grade and type of steel used. However, on average, steel coils typically have a tensile strength ranging from 300 to 2,500 megapascals (MPa).

- Q: How long can steel coils be stored before they need to be used?

- Steel coils can typically be stored for an extended period of time, ranging from a few months to several years, depending on various factors such as the coating, storage conditions, and the type of steel. However, it is generally recommended to use or sell steel coils within a year or two to ensure their optimal quality and performance.

- Q: I have a new stainless steel trash compactor under a butcher block counter. We refinished the countertop, but unfortunately the person who did it wasn't careful with the orbital sander and sanded the top edge of the stainless steel compactor door, ruining the finish. The sander marks are not deep - just surface scratches - but they are unsightly. Is there any way to restore the finish to the stainless steel without having to buy a new door?

- How To Refinish Stainless Steel

- Q: so I am trying to drill holes in stainless steel shelving to hang something but my drill wont make any more than a small dent in the steel. I bought a bit for hard metals but it didn't do any better. I have an admittedly small drill (9.6v). is that the problem? do I just need a more powerful drill? any serious advice is appreciated. thanks

- Just put drops of water at the spot of drilling to keep your drill bit cool. The reason your drill bit gets dull is because it gets hot and melts.You may need to re sharpen your drill bit or purchase a new one.

- Q: How are steel coils inspected for bendability?

- Steel coils are inspected for bendability through a combination of visual examination, mechanical testing, and dimensional analysis. Visual inspection involves identifying any visible defects such as cracks, dents, or surface irregularities that could affect the coil's bendability. Mechanical testing is conducted to measure the coil's resistance to bending and evaluate its flexibility. This includes performing bend tests to determine the coil's ability to withstand a specified degree of bending without breaking or cracking. Additionally, dimensional analysis is performed to ensure that the coil meets the required thickness, width, and length specifications, as these factors also impact its bendability.

- Q: I work with stainless steel a lot and I know it's rust resistant but it's definitly not STAIN resistant. You might be able to remove some stains easier from it than you can from some other surfaces but when it does stain, its hard as heck to clean it. It takes forever to scrub stains off my stainless steel pans so maybe it should just be called rustless steel?

- It is called stainless because it is much more highly resistant to rust and corrosion. It is stainless in camparison to other steels, such as carbon steel.

- Q: How are steel coils loaded onto trucks or containers?

- Steel coils are typically loaded onto trucks or containers using specialized equipment such as cranes, forklifts, or coil trailers. The coils are lifted and secured onto the truck or container using straps, chains, or clamps to ensure safe transportation.

- Q: What is the average size of a steel coil?

- The average size of a steel coil can vary depending on the specific application and industry. However, in general, steel coils typically have a width ranging from 600mm to 2000mm and a weight between 2 to 25 metric tons.

- Q: How are steel coils used in the manufacturing of intake manifolds?

- Steel coils are typically used in the manufacturing of intake manifolds as the primary material for forming the manifold's structure. These coils are shaped and cut into specific dimensions to create the necessary components, such as runners and plenums, which help regulate the flow of air and fuel mixture into the engine. The steel coils are often subjected to additional processes, including welding, machining, and surface treatments, to ensure the final intake manifold meets the required specifications and performance standards.

Send your message to us

Hot-dip Zinc Coating Steel Sheets in Coils of Prime Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords