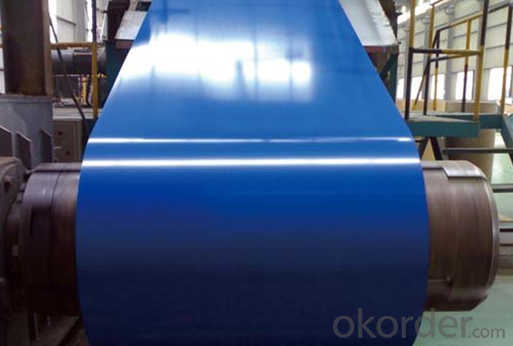

Hot-Dip Galvanized Steel/Pre-Painted Steel Coil for Tiles Thicness0.18mm-1.5mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications;

1. Aluzinc coating mass: 30g-275g/sqm

2. Coil weight: 4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

8. Supply Ability: 30000MT/month

9. Application: The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

10. Delivery time: Within 30 days after the receipt of L/C or Signed the contract or according to customer's requirement.

Special design available according to requirement; Anti-corrosion And high-temperature resistant with black painting; All the production process Are made under the ISO9001: 2000 strictly

Package:

Sea worthy Export Packing Standard export and seaworthy packing. (waterproof paper and metal sheet protection with

fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil)

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

- Q: What are the dimensions of steel coils used in the metal furniture industry?

- The dimensions of steel coils used in the metal furniture industry can vary depending on the specific requirements of each manufacturer. However, commonly used dimensions include coil widths ranging from 24 to 60 inches (61 to 152 cm) and coil diameters ranging from 36 to 72 inches (91 to 183 cm). The thickness of the steel coils can also vary, typically ranging from 0.020 to 0.250 inches (0.05 to 0.64 cm). These dimensions allow manufacturers to efficiently produce various types of metal furniture, such as chairs, tables, and cabinets, by utilizing the steel coils as raw materials for their production processes.

- Q: I had heard of steel braided fuel lines but ive also seen some air and coolant lines that are steel braided. Are these commonly used? I guess what I'm asking is if its a good idea to use them.

- Steel braided line are mainly use in turbulence areas, where they need to be protected. i would recommend replacing your brake line with it but not your coolant or air lines. there are other materials that are well suitable for coolant and air lines.

- Q: What are the different types of steel coil treatments?

- Enhancing the properties and performance of steel coils involves various types of treatments. The treatments include: 1. Heat treatment known as annealing. It involves heating the steel coil to a specific temperature and gradually cooling it. This treatment alleviates internal stresses, enhances ductility, and boosts the overall strength of the coil. 2. Chemical treatment called pickling. It entails submerging the steel coil in an acid or chemical solution to eliminate impurities, scale, and rust from the surface. This treatment enhances the surface finish and cleanliness of the coil. 3. Application of a protective coating such as oil. A thin layer of oil or another protective substance is applied to the surface of the steel coil. This treatment prevents corrosion, improves lubricity, and safeguards the coil during storage and transportation. 4. Galvanizing, a process that involves coating the steel coil with a layer of zinc. This protective layer shields the coil from corrosion, creating a barrier between the steel and the surrounding environment. It ensures long-term durability and resistance to rust. 5. Tempering, a heat treatment process that includes heating the steel coil to a specific temperature and swiftly cooling it. This treatment enhances the toughness and strength of the coil, making it more resistant to impact and deformation. These are just a few instances of the various types of steel coil treatments commonly employed. Each treatment has its own unique purpose and advantages, and the choice of treatment will depend on the desired properties and applications of the coil.

- Q: How are steel coils inspected for yield strength using tensile testing?

- Steel coils are inspected for yield strength using a testing technique called tensile testing. Tensile testing involves subjecting a sample of the steel coil to controlled tension until it reaches its breaking point. This test helps determine various mechanical properties of the steel, including yield strength. To inspect steel coils for yield strength using tensile testing, a small strip of the coil is cut and prepared for testing. The strip is placed in a tensile testing machine, which consists of two grips that firmly hold the strip at opposite ends. The machine then applies a steadily increasing force to the strip, causing it to elongate until it ultimately breaks. During the test, the machine measures the force applied and the elongation of the strip. The yield strength is determined by identifying the point on the stress-strain curve where the material begins to deform plastically, or exhibit permanent deformation without any increase in load. The yield strength is typically reported as the stress required to cause a specific amount of plastic deformation, commonly 0.2% or 0.5%. This value represents the maximum stress that the steel can withstand without permanent deformation occurring. By conducting tensile testing on a sample of the steel coil, it is possible to determine its yield strength. This information is crucial for ensuring the quality and reliability of the steel coil, as it indicates the maximum stress it can withstand before permanent deformation occurs. Additionally, this testing method allows for the evaluation of other mechanical properties, such as ultimate tensile strength, elongation, and modulus of elasticity, providing a comprehensive understanding of the steel's performance characteristics.

- Q: How are steel coils inspected for surface defects after processing?

- Steel coils are inspected for surface defects after processing through a visual inspection process. Specially trained inspectors carefully examine the coils for any visible defects such as scratches, dents, or irregularities in the surface. They use advanced lighting techniques and magnification tools to ensure a thorough inspection. Additionally, automated systems may also be employed to detect and flag any defects that may have been missed during the visual inspection.

- Q: Would the Ruger Sr22 pistol or the SW MP 15-22 be any good for the steel challenge?

- Steel plates are very difficult for a .22lr

- Q: How are steel coils protected from extreme weather conditions?

- Steel coils are typically protected from extreme weather conditions using various methods such as covering them with waterproof wraps, storing them in climate-controlled warehouses, or applying anti-corrosion coatings. These measures ensure that the coils are shielded from moisture, temperature fluctuations, and other environmental factors that could potentially damage or degrade the steel.

- Q: i mean the properties include the elasticity, impact load and ductility. am doing assignment about the perfect material that should be possessed by spring and i found alloy steel is the perfect and am confused whether stainless steel is the same with alloy steel ?

- Is Stainless Steel An Alloy

- Q: What are the environmental and social impacts of mining, processing and using steel?

- It contains less than 0.25 % carbon. These steels are hot worked and produced for beam and structural application. Low carbon steels are not hardened appreciably by hardening process of heat treatment. A decrease in carbon content improves ductility mild steels are used for wires, rods, thin sheets, solid drawn tube, boiler plates, steel joints, channels and angles, structural sections, drop forgings. they are further classifies into dead mild, and mild steel dead mild steel It contains 0.05% to 0.15% carbon. It is used for making steel wires, sheets, rivets, screws, pipe, nail and chain. It has a tensile strength of 390 N/mm2 and a hardness of about 115 BHN. there are many company which produce their products from this raw material like tube, pipe, S31803 Duplex tube fitting, pipe fitting etc

- Q: How are steel coils used in the production of structural steel?

- Steel coils are widely used in the production of structural steel due to their versatility and efficiency. These coils, which are made by rolling steel into a cylindrical shape, serve as the raw material for various structural steel products. One of the primary uses of steel coils in the production of structural steel is in the manufacturing of beams and columns. These coils are processed in steel mills, where they undergo cutting, shaping, and bending to form the desired profiles. Beams and columns are essential components of any building or infrastructure project as they provide support and stability. Steel coils are also used in the fabrication of steel plates, which are widely used in the construction industry. These plates are used for flooring, cladding, and roofing purposes, adding strength and durability to structures. By using steel coils as the starting material, manufacturers can produce steel plates of various thicknesses and sizes according to project requirements. Furthermore, steel coils are an integral part of the production process for pipes and tubes. These coils are formed into a cylindrical shape and then welded or seamless to create pipes and tubes of different diameters. Steel pipes and tubes are vital for various applications, including water and gas transportation, structural frameworks, and industrial systems. In addition to these applications, steel coils are also used in the production of other structural steel products such as angles, channels, and hollow sections. These products are widely used in construction projects, providing structural support, reinforcement, and aesthetic appeal. Overall, steel coils play a crucial role in the production of structural steel by serving as the raw material for various products. Their versatility, ease of processing, and strength make them an ideal choice for manufacturers, ensuring the production of high-quality and reliable structural steel components.

Send your message to us

Hot-Dip Galvanized Steel/Pre-Painted Steel Coil for Tiles Thicness0.18mm-1.5mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords